Motor vehicle front end

A technology for motor vehicles and heads, which is applied to vehicle parts, machines/engines, bodywork, etc., and can solve problems such as high propulsion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

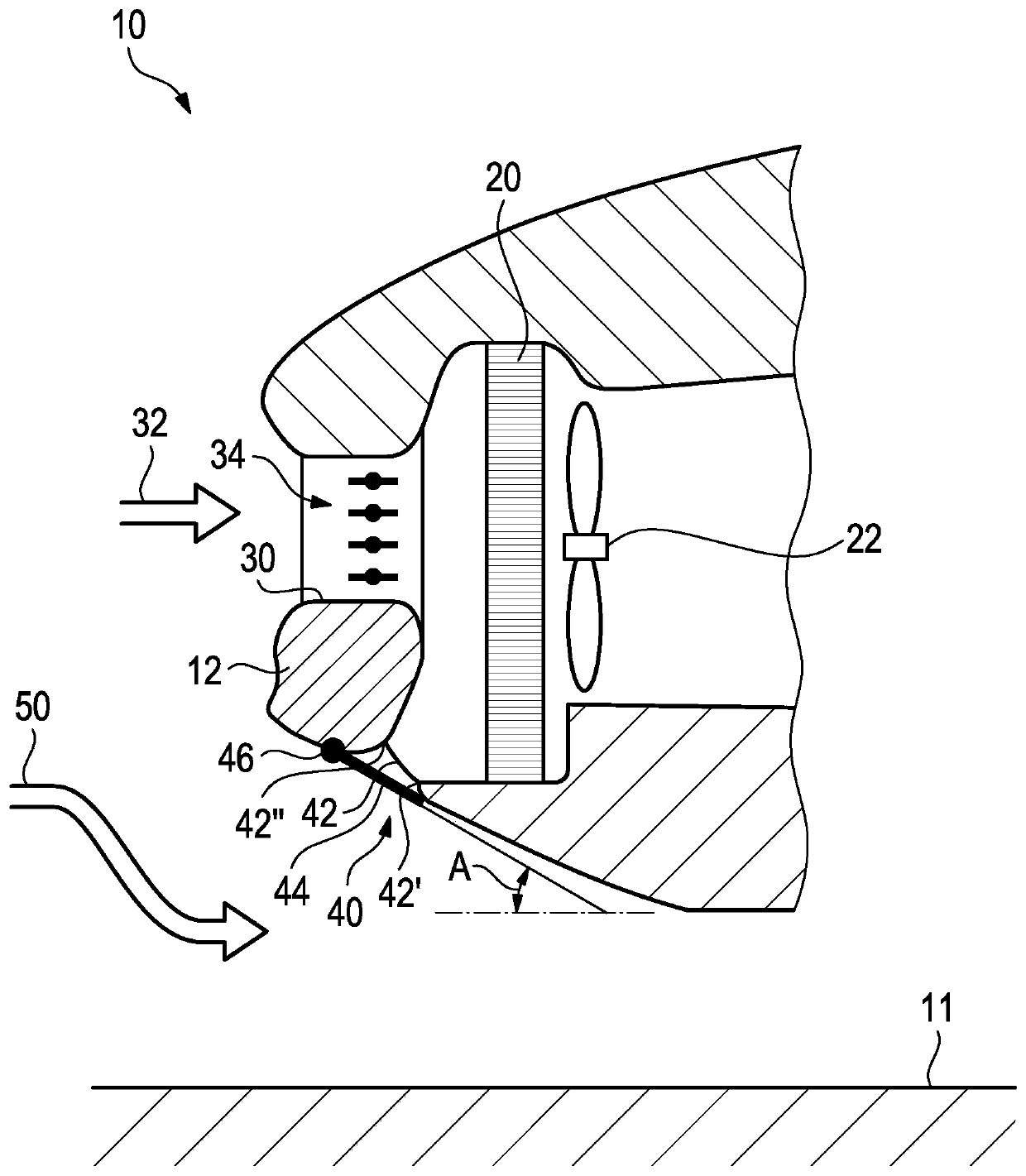

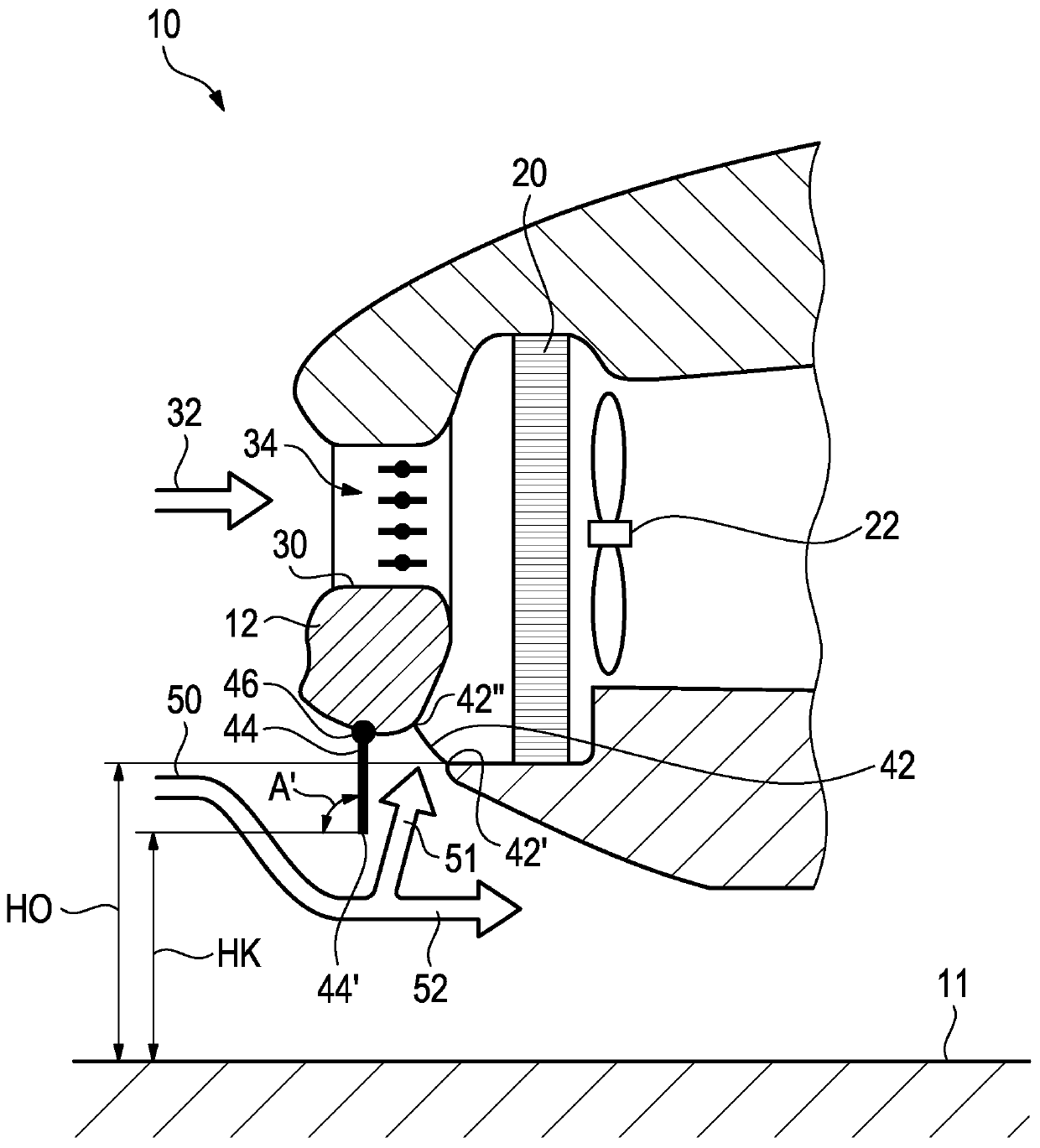

[0035] exist figure 1 and 2 A motor vehicle front 10 of a motor vehicle with a front inclination greater than 15° is shown in FIG. In the motor vehicle head 10 are arranged a heat exchanger 20 , an electric fan 22 arranged downstream of the heat exchanger 20 , and a cooling air assembly for controlling the air supply to the heat exchanger 20 . The cooling air assembly guides and controls the upper air path 32 and the lower air path 50 , both of which can lead to the heat exchanger 20 if necessary.

[0036] The upper air path 32 essentially consists of an upper, forwardly opening inlet opening 30 having a controllable flap arrangement 34 for fluidically opening or closing the inlet opening 30 . The upper air path 32 is arranged above the horizontal body part 12 designed as a bumper and approximately at the level of the heat exchanger 20 .

[0037] Below the horizontal body part 12 there is provided an essentially downwardly opening air intake opening 42 which is associated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com