Concrete admixture prepared from sulfur-fixing ash and sulfur-fixing residue, and preparation method thereof

A sulfur-fixing ash and admixture technology, applied in the field of concrete, can solve the problems of increasing the economic burden of ash yard maintenance costs, environmental problems, waste of land, etc., and achieve the effect of superior performance, low cost, and promotion of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

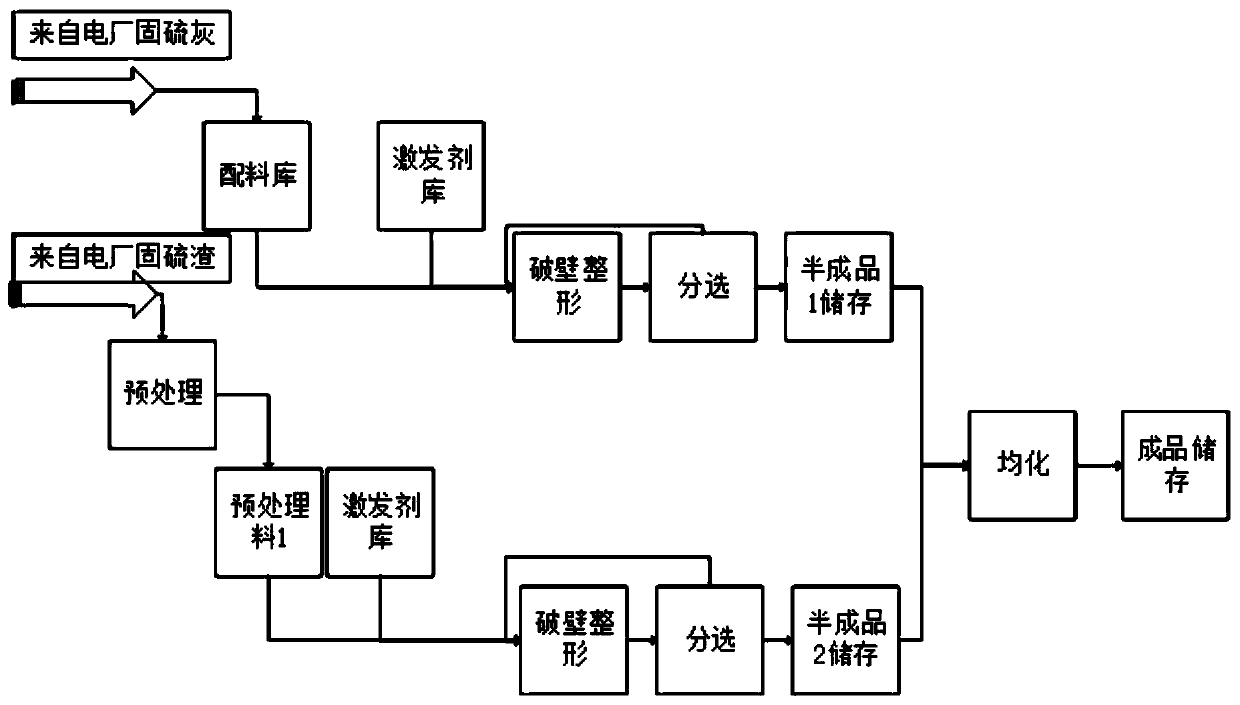

[0027] A concrete admixture developed from sulfur-fixing ash and a preparation method thereof, comprising the following steps (see attached figure 1 ):

[0028] (1) Pretreatment: pretreat the undisturbed sulfur-fixing slag from the power plant to obtain pretreatment material 1

[0029] (2) Alkali excitation: Pneumatically convey the undisturbed sulfur-fixed ash from the power plant to the bucket elevator of the batching warehouse, lift it into the batching warehouse by the bucket elevator, measure it through the rotor scale at the bottom of the batching warehouse, and then pass it through the activator warehouse 1 to give Add 1.0-1.5% alkaline activator to the undisturbed sulfur-fixing ash; add an alkaline activator to the pretreatment material 1 in a ratio of 1.0-1.5% through the activator library 2;

[0030] (3) Wall breaking and shaping and sorting: the undisturbed sulfur-fixing ash added with 1.0-1.5% of the alkaline activator is sent into the superfine powder tube mill f...

Embodiment 2

[0033] A concrete admixture developed by using the sulfur-fixing ash prepared in Example 1 was used for trial batching of concrete, and the performance of the trial batched concrete was tested.

[0034] 1. Grouping situation:

[0035] ① Control group: take C30 concrete as the control group, and its basic mix composition is shown in Table 1;

[0036] ②Experimental group: the concrete that is prepared with the concrete admixture that a kind of sulfur-fixed ash slag that obtains in embodiment 1 is developed is experimental group, and its mixing ratio composition is shown in Table 2;

[0037] Table 1 The composition of the basic mix ratio of the control group

[0038] P.0.42.5 cement water Middle sand gravel Admixture 360kg 160kg 750kg 1140kg 9.0kg

[0039] Table 2 The composition of the experimental group mix ratio

[0040] P.0.42.5 cement Concrete admixture developed from sulfur-fixed ash water Middle sand gravel Admixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com