Hydraulic large-volume crack-resistant concrete and preparation method thereof

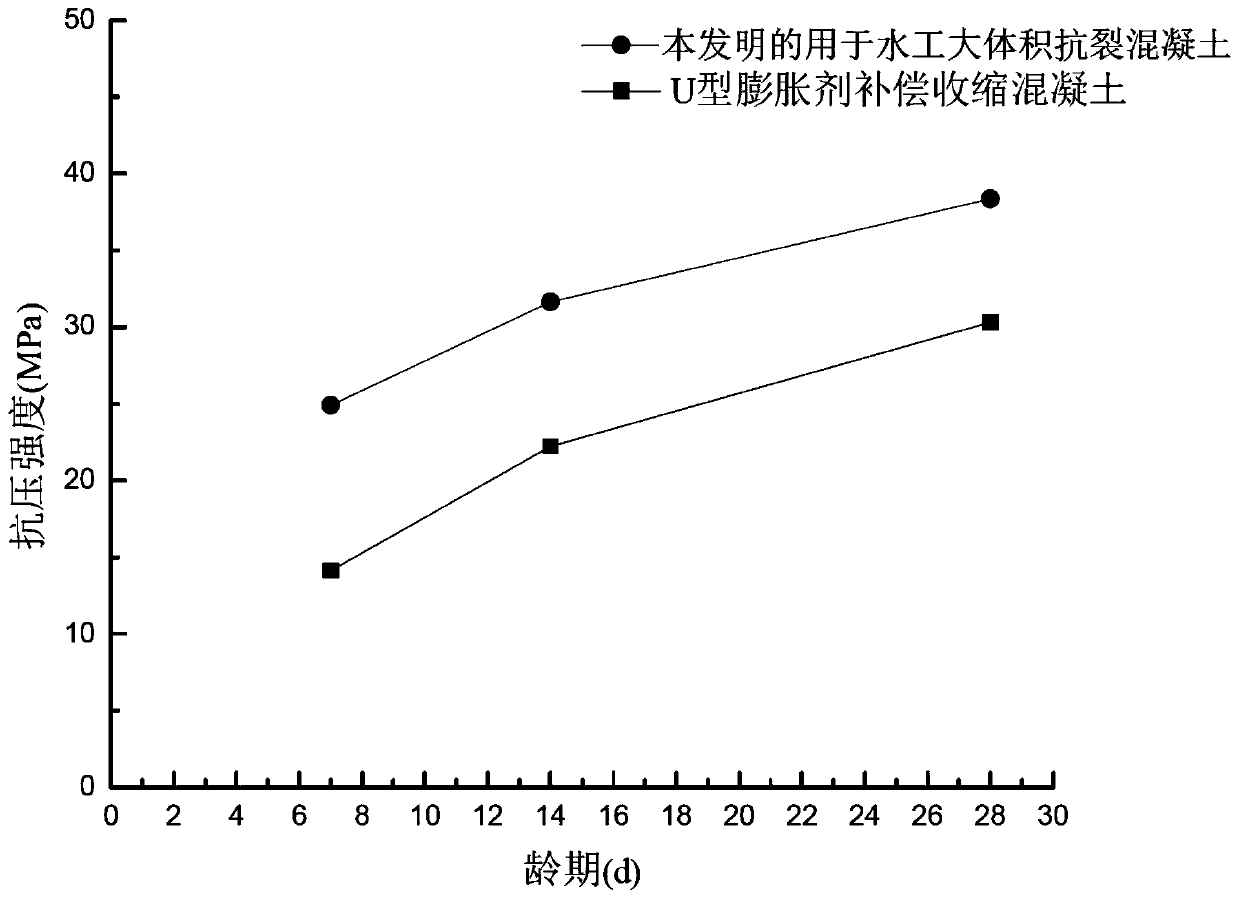

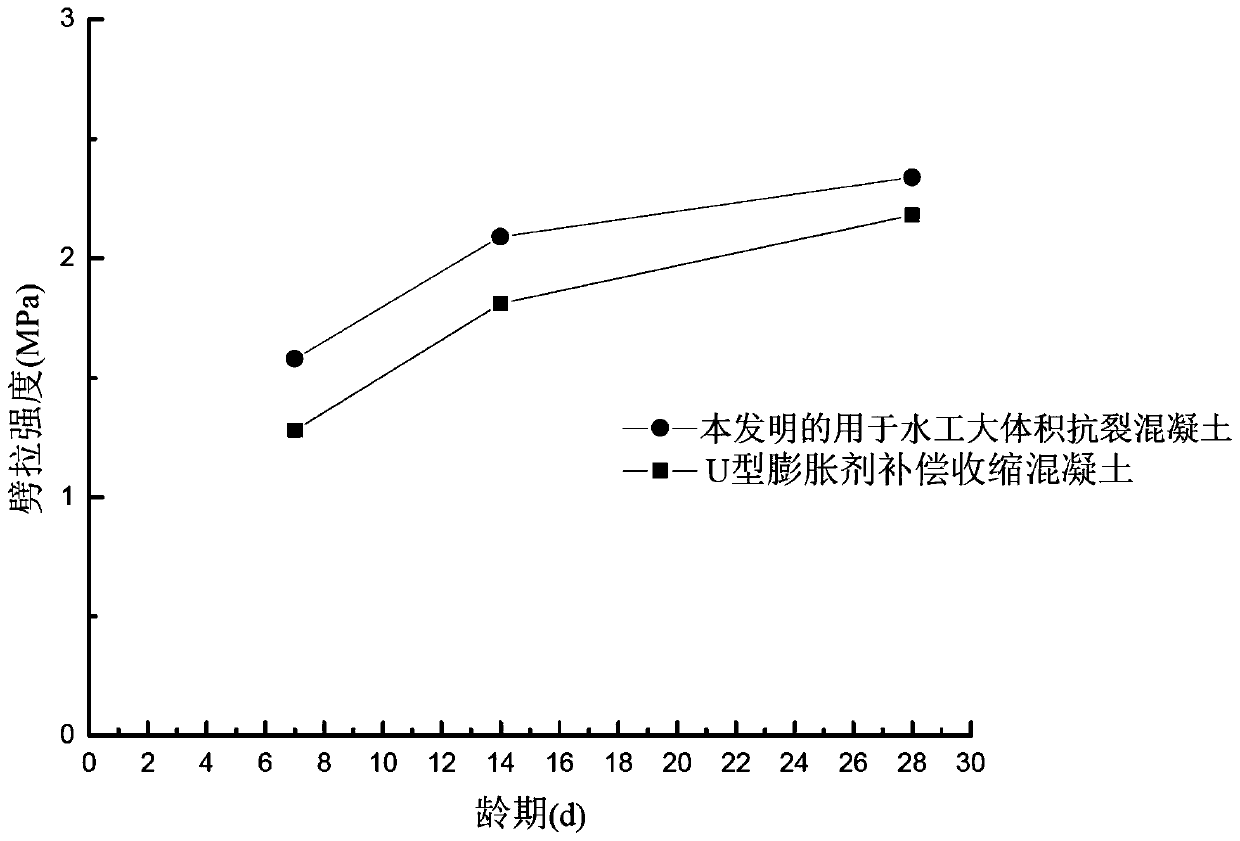

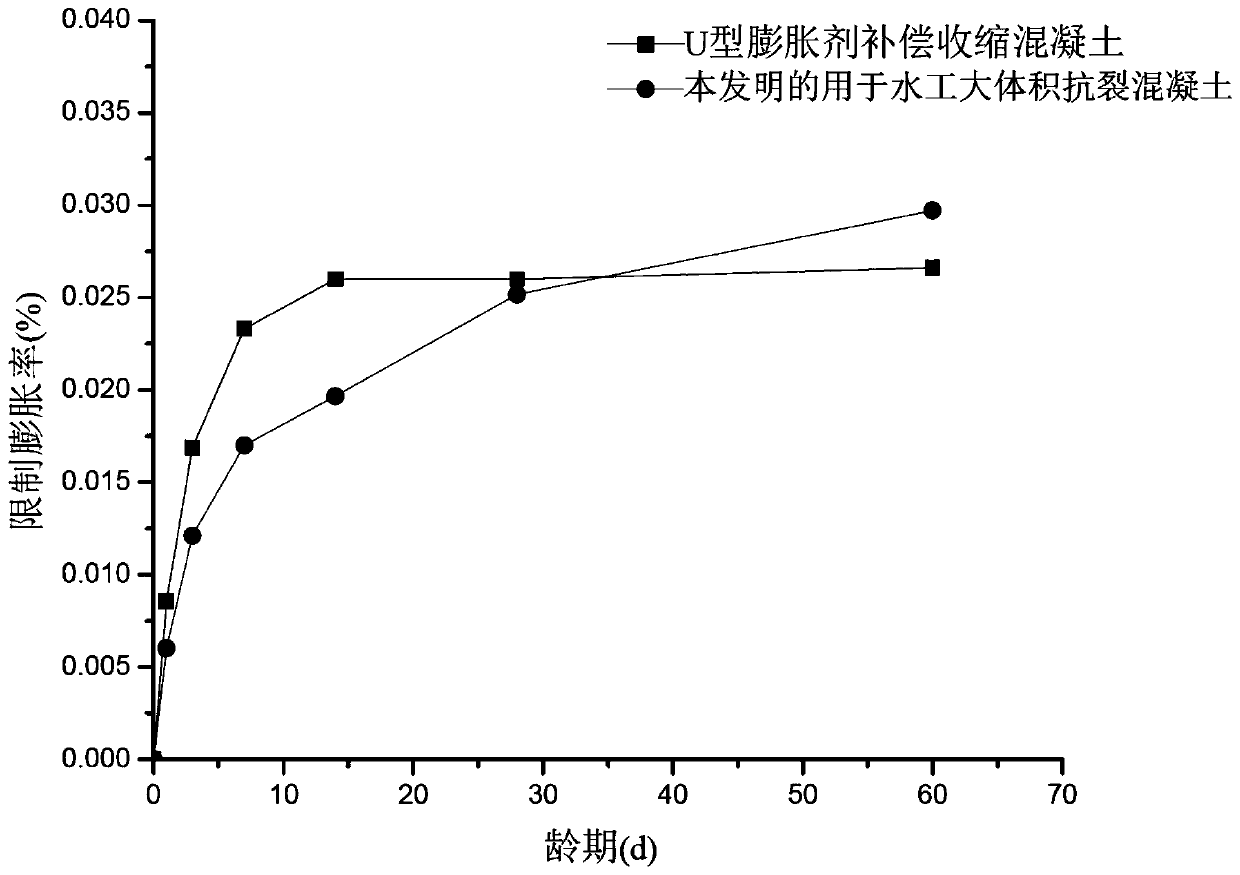

A large-volume, concrete technology, applied in the field of concrete materials, can solve the problems of insufficient crack resistance of shrinkage-compensated concrete, and achieve the effects of reducing cracks, improving crack resistance, and increasing splitting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0032] This embodiment provides a large-volume anti-crack concrete for hydraulic engineering, the components of the large-volume anti-crack concrete for hydraulic engineering include: cement, fly ash, expansion agent, water, sand, gravel, and water reducing agent; Among them, the mass ratio of each component is: cement 5-10%, fly ash 2-4%, expansion agent 1-2%, water 5-10%, sand 28-32%, gravel 50-55%, The water reducing agent is 0.05-0.1%, and the sum of the mass percentages of each component satisfies 100%.

[0033] Wherein, the cement is 42.5 grade ordinary Portland cement; the fly ash is F class I grade fly ash; the expansion agent includes UEA expansion agent and MgO expansion agent; the sand is inactive natural river sand , the fineness modulus is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com