Method for controlling gas production and viscosity increasing of exposure vinegar

A viscous and microbial technology, applied in the field of fermented condiment processing, can solve the problems of gas production, increased viscosity, low output, long cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

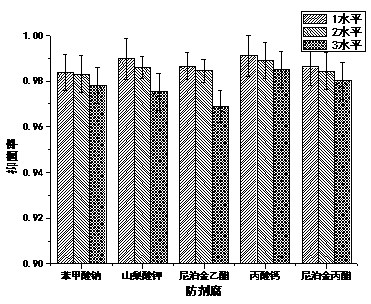

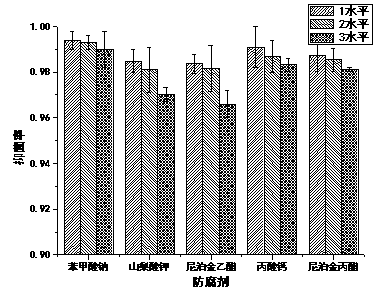

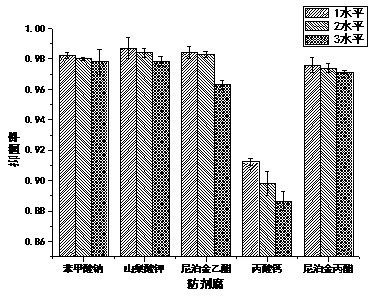

Image

Examples

Embodiment Construction

[0025] A method for preventing and controlling gas production and viscosity increase of sun-dried vinegar, specifically comprising the following steps:

[0026] (1) Separation of microorganisms: Dilute the gas-producing and viscous sun-dried vinegar A to 10% under aseptic conditions. -1 , draw 0.3ml, add it to the culture dish with plate counting agar medium, use a sterile coating stick to gently spread evenly on the culture and surface, seal the culture dish, and place it upside down in a constant temperature incubator and anaerobic incubator, Cultivate at 30°C for 3-5 days, and inoculate normal vinegar B into the above medium as a control;

[0027] (2) Purification: select a plate with a colony count between 20-30, use the plate counting agar medium to carry out streak separation and purification for 3 times, and use the plate counting agar slant medium after purification to preserve it at a temperature of 4°C for subsequent use;

[0028] (3) Screening of miscellaneous bact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com