Aramid paper-based material beating and defrosting equipment

A base material, aramid paper technology, applied in pulp beating method, synthetic cellulose/non-cellulose material pulp/paper, papermaking, etc., can solve the damage of bedknives and flying knives, accidents caused by weeds flying out, etc. problems, to achieve the effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

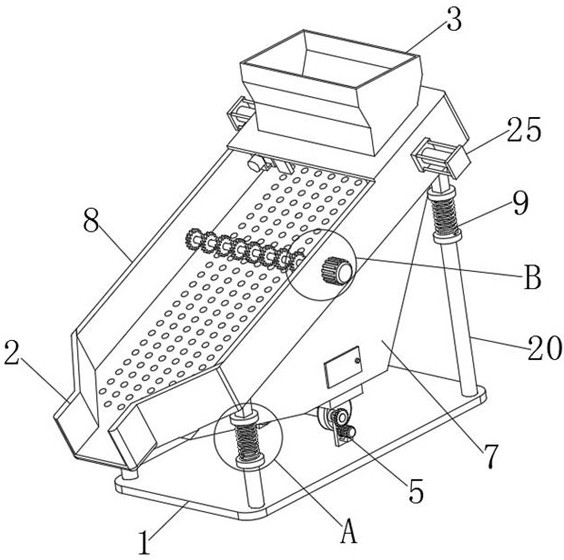

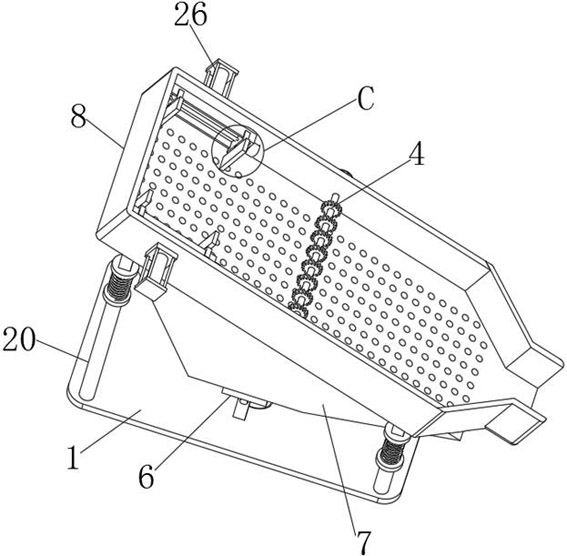

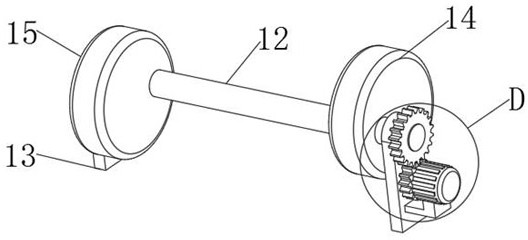

[0029] Specific implementation method: when performing feeding pretreatment on aramid pulp, first, the rotating motor 16 runs, so that the driving gear 18 drives the driven gear 19 to rotate, and because the driven gear 19 is fixedly sleeved on one end of the support shaft 12 , so that the support shaft 12 respectively drives the first rotating wheel 14 and the second rotating wheel 15 to rotate at the bottom of the bottom plate 6, and at the same time, due to the position deviation between the first rotating wheel 14 and the second rotating wheel 15 and the supporting shaft 12 The center of the circle, and then make the first rotating wheel 14 and the second rotating wheel 15 run irregularly at the bottom of the base plate 6, and then realize the effect of vibrating the vibrating screen 8.

[0030]The position that the first rotating wheel 14 and the second rotating wheel 15 are connected with the supporting shaft 12 deviates from the center of circle of the first rotating whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com