Inorganic porous support-zeolite membrane complex, method for producing same and separation method using same

An inorganic porous, zeolite membrane technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problem of low heat resistance of polymer membranes, low chemical resistance of polymer membranes, limited scope of application, etc. problem, to achieve the effect of excellent acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

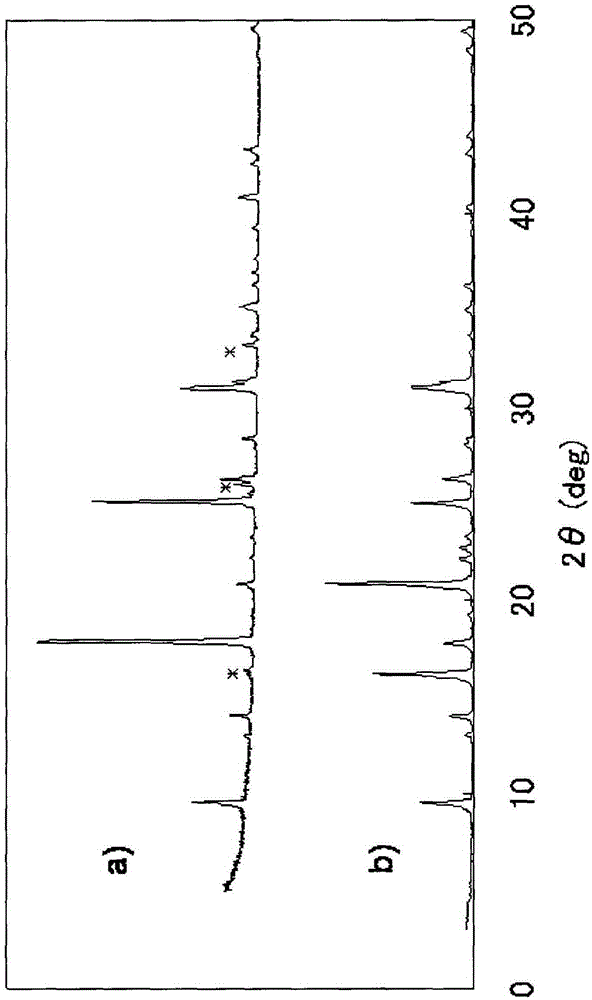

Embodiment 1

[0177] In order to produce a CHA-type zeolite membrane, an aqueous solution of N,N,N-trimethyl-1-adamantylammonium hydroxide (TMADOH) was prepared referring to the description in USP4544538. Examples are given below.

[0178] 5.5 g of 1-adamantanamine (manufactured by Aldrich) was dissolved in 75 ml of methanol, 24.2 g of potassium carbonate was added, and stirred for 30 minutes. 10 ml of iodomethane was added dropwise thereto, followed by stirring for 1 day and night. Then 50 ml of dichloromethane was added and the solid was filtered. The solvent of the obtained solution was removed by an evaporator to obtain a solid. After adding 130 ml of dichloromethane to the solid, the operation of filtering and removing the solvent was repeated twice. Thereafter, the obtained solid was recrystallized with methanol, the recrystallized solid was filtered, washed with diethyl ether, and dried to obtain N,N,N-trimethyl-1-adamantylammonium iodide (TMADI). Thereafter, this TMADI was diss...

Embodiment 2

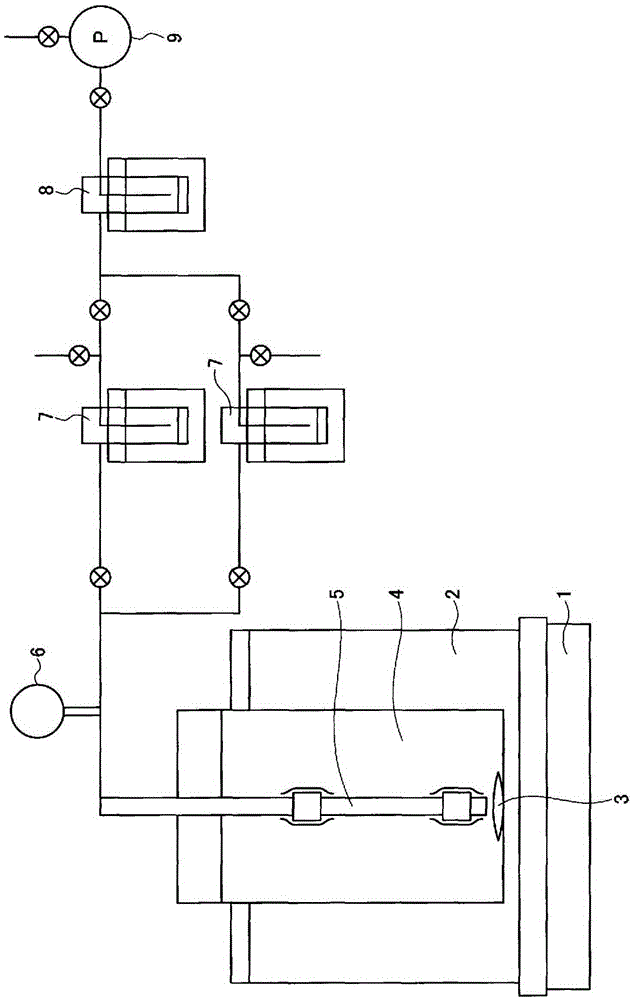

[0189] By directly hydrothermally synthesizing the CHA type zeolite on the inorganic porous support body, the inorganic porous support body CHA type zeolite membrane complex is produced.

[0190] As a reaction mixture for hydrothermal synthesis, the following reaction mixture was prepared.

[0191] Add aluminum hydroxide (containing 53.5% by weight Al 2 o 3 , manufactured by Aldrich Corporation) 0.88 g was dissolved by stirring to obtain a transparent solution. Add thereto 2.95 g of N,N,N-trimethyl-1-adamantylammonium hydroxide (TMADOH) aqueous solution (containing 25% by weight of TMADAOH, manufactured by Sachem) as an organic template, and then add colloidal dioxide 10.5 g of silicon (SNOWTEX-40 manufactured by Nissan Chemical Co., Ltd.) was stirred for 2 hours to prepare a mixture for hydrothermal synthesis.

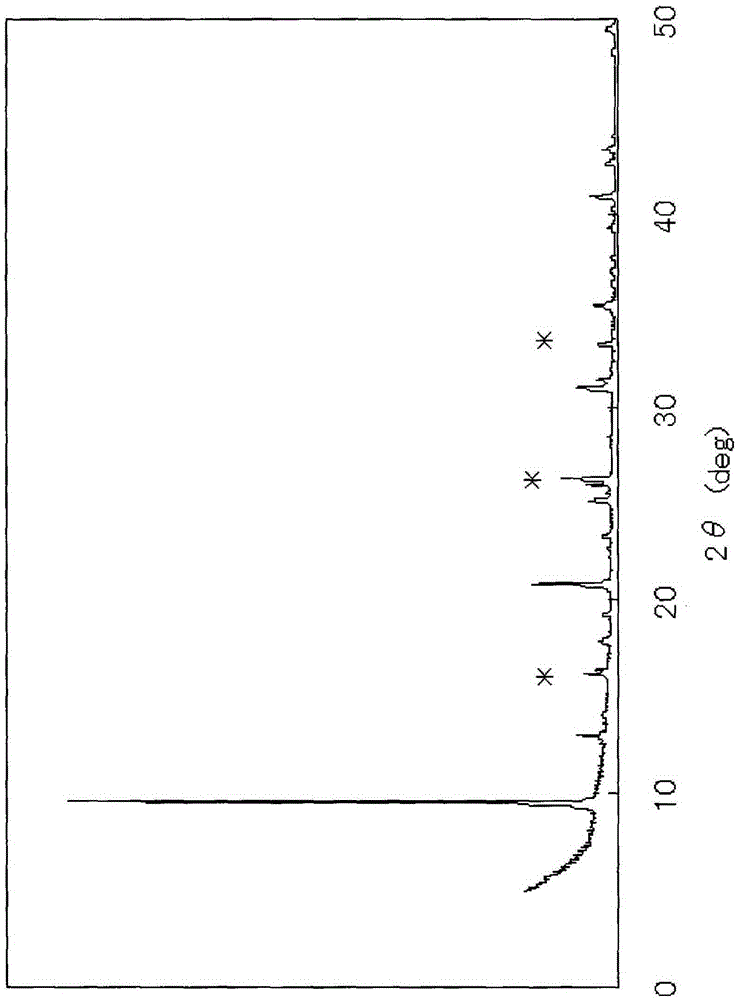

[0192] As the inorganic porous support, a support obtained by the same treatment as in Example 1 was used. Before hydrothermal synthesis, CHA-type zeolite seed cr...

Embodiment 3

[0197] By directly hydrothermally synthesizing the CHA type zeolite on the inorganic porous support body, the inorganic porous support body-CHA type zeolite membrane complex is prepared.

[0198] As a reaction mixture for hydrothermal synthesis, the following reaction mixture was prepared.

[0199] Aluminum hydroxide (containing 53.5% by weight of Al 2 o 3 , manufactured by Aldrich Corporation) 0.88 g was dissolved by stirring to obtain a transparent solution. Add thereto 2.37 g of N,N,N-trimethyl-1-adamantylammonium hydroxide (TMADOH) aqueous solution (containing 25% by weight of TMADAOH, manufactured by Sachem) as an organic template, and then add colloidal dioxide 10.5 g of silicon (SNOWTEX-40 manufactured by Nissan Chemical Co., Ltd.) was stirred for 2 hours to prepare a mixture for hydrothermal synthesis.

[0200] As the inorganic porous support, a support obtained by the same treatment as in Example 1 was used. Before hydrothermal synthesis, a CHA-type zeolite seed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com