High-side wall concrete construction joint zero-defect construction method

A construction method and concrete technology, applied in building components, building insulation materials, buildings, etc., can solve problems such as construction joint defects, construction joint defects, construction joint surface fracturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

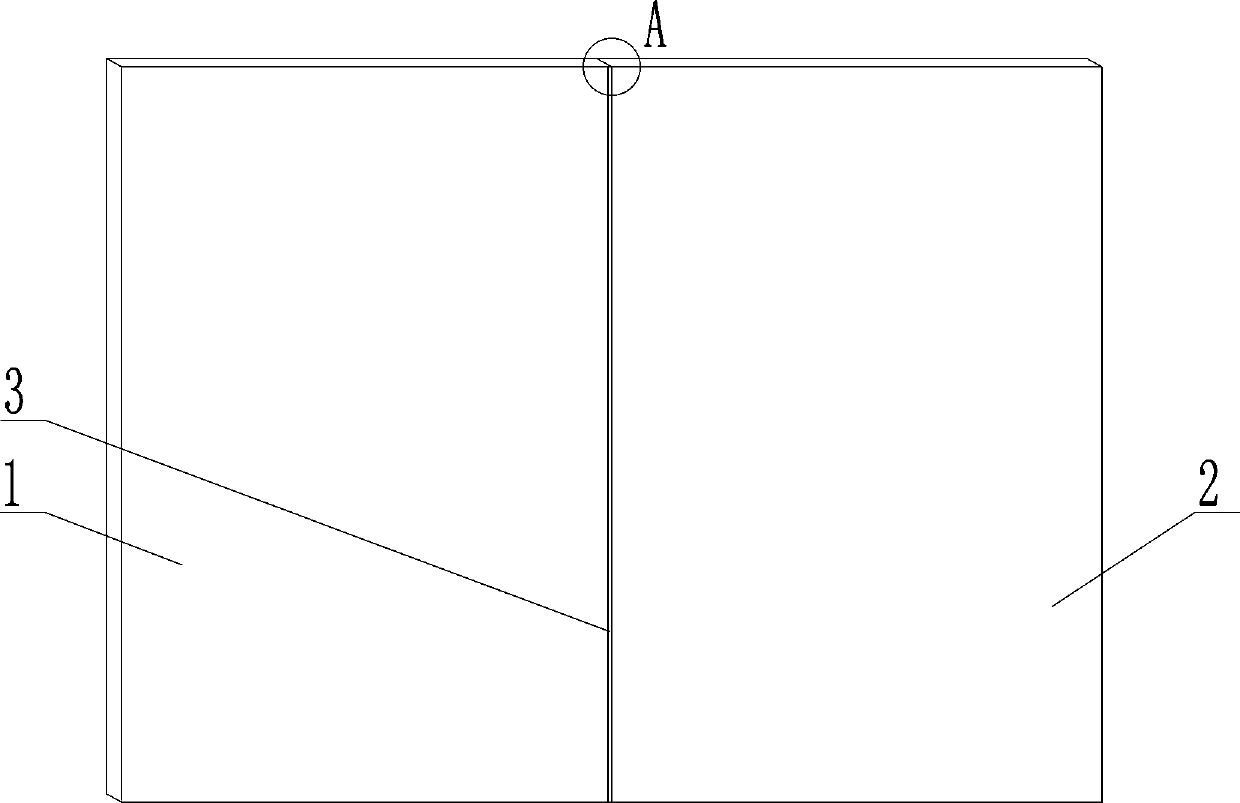

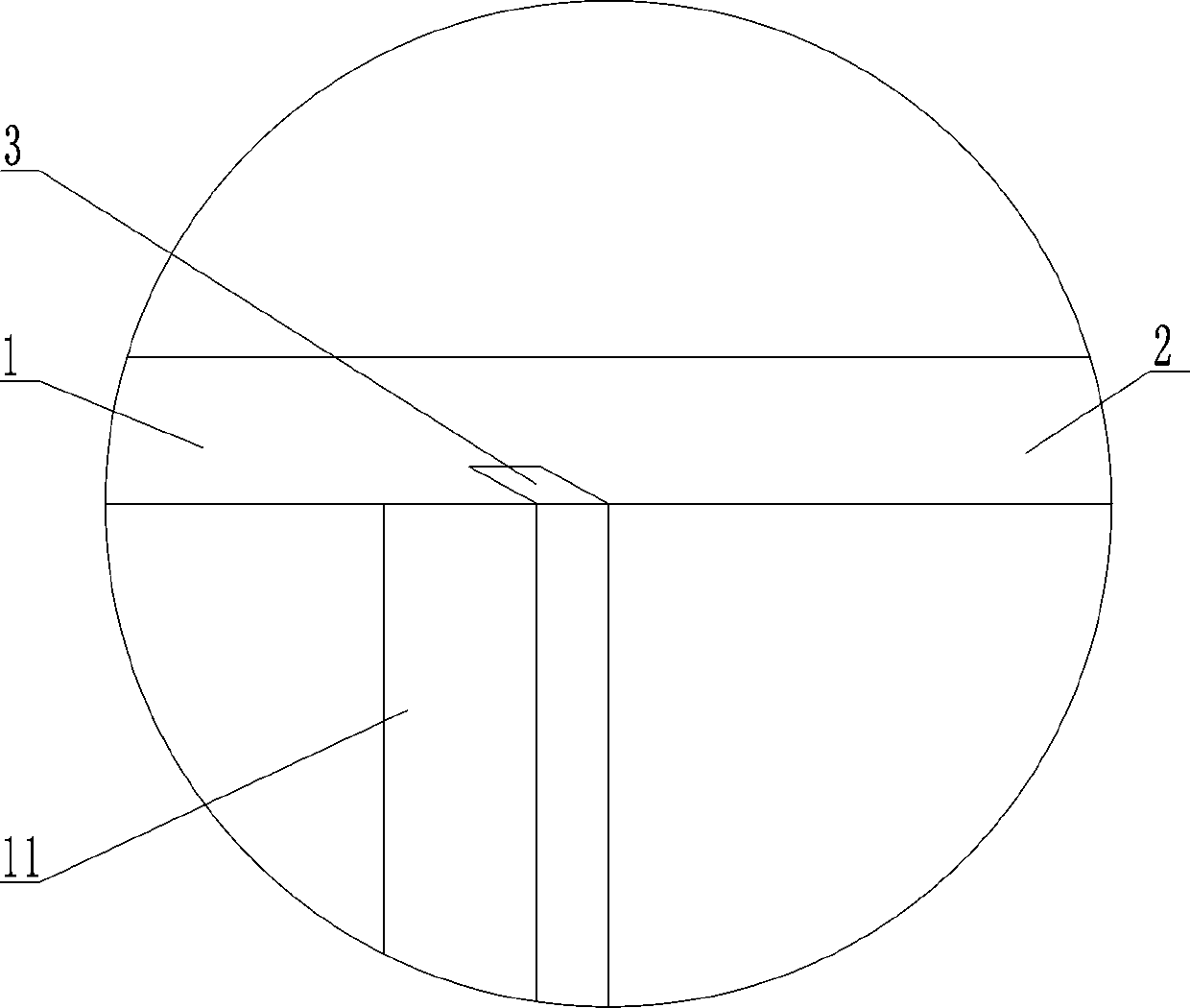

[0036] Such as Figure 1~Figure 2 Among them, a defect-free construction method for high side wall concrete construction joints, it includes the following steps:

[0037] Step 1, processing the overlapping surface of the poured bin 1;

[0038] Step 1-1, circle the uneven part of the concrete;

[0039] Step 1-2, grinding the uneven parts;

[0040] Step 1-3, testing the flatness;

[0041] Step 2, cutting construction joints;

[0042] Step 2-1, draw the cutting line;

[0043] Step 2-2, circular cutting;

[0044] Step 3, construction joint cleaning;

[0045] Step 3-1, cutting surface cleaning;

[0046] Step 3-2, clean up the grinding area 11;

[0047] Step 4, lap control;

[0048] Step 4-1, paste the double-sided tape;

[0049] Step 4-2, control the strength of the roof wire;

[0050] Step 4-3, double-sided tape compression thickness control;

[0051] Step 4-4, detecting the tightness of the lap seam.

[0052] In the preferred solution, in the step 1-1, the hanging is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com