Porous pneumatic damper

An aerodynamic damper and aerodynamic damping technology, used in bridge parts, bridge construction, building components, etc., can solve the problems of high temperature heat dissipation, difficult to stabilize control, leakage, etc., to reduce construction cost and maintenance cost, achieve heat dissipation effect, avoid temperature The effect of rising too much

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

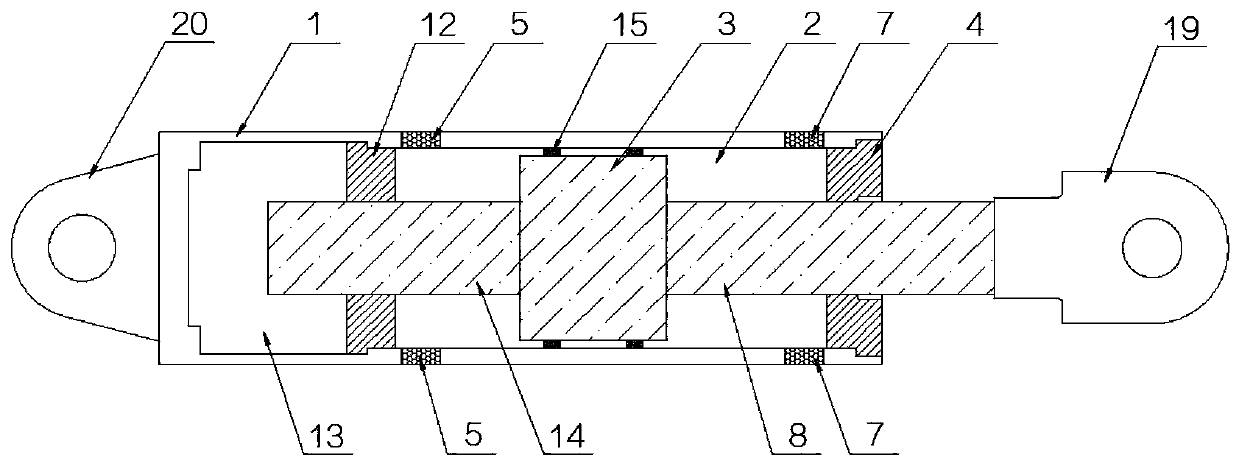

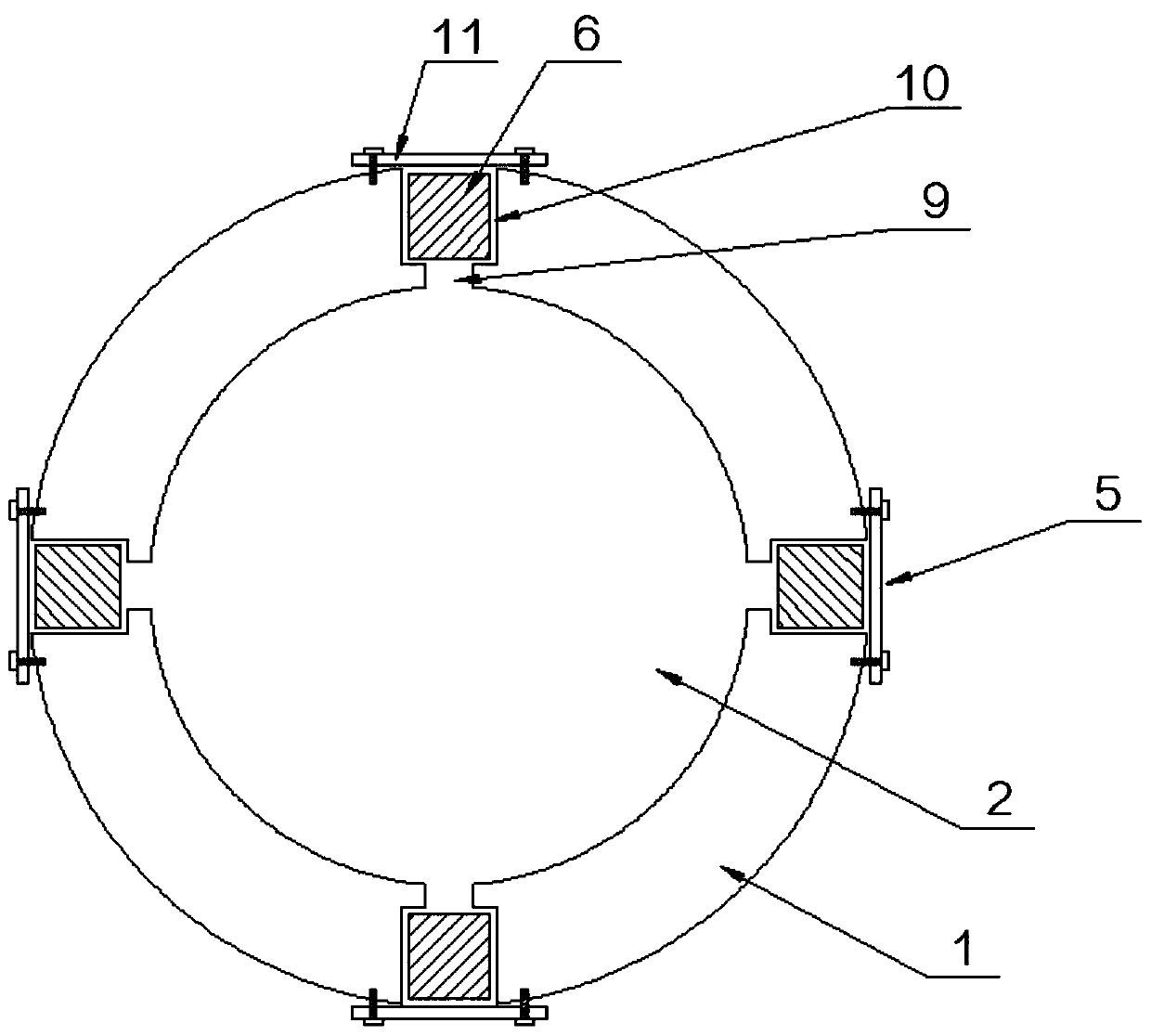

[0028] Such as Figure 1-3 As shown, a porous pneumatic damper includes an outer sleeve 1, a cavity 2 is opened in the outer sleeve 1, a piston 3 is arranged in the cavity 2, and one end of the outer sleeve 1 is opened A first sealing member 4 is fixedly arranged at the place;

[0029] One end of the outer sleeve 1 is provided with a first pneumatic damping hole 5, and the other end of the outer sleeve 1 is provided with a second pneumatic damping hole 7, and the first pneumatic damping hole 5 and the second pneumatic damping hole 7 Porous medium valve bodies 6 are respectively fixed inside, the piston 3 is located between the first pneumatic damping hole 5 and the second pneumatic damping hole 7, a first piston rod 8 is arranged on one side of the piston 3, and the The first piston rod 8 passes through the first sealing member 4 and passes out of the outer sleeve 1 .

[0030] One end of the outer sleeve 1 is provided with a plurality of first pneumatic damping holes 5 at in...

Embodiment 2

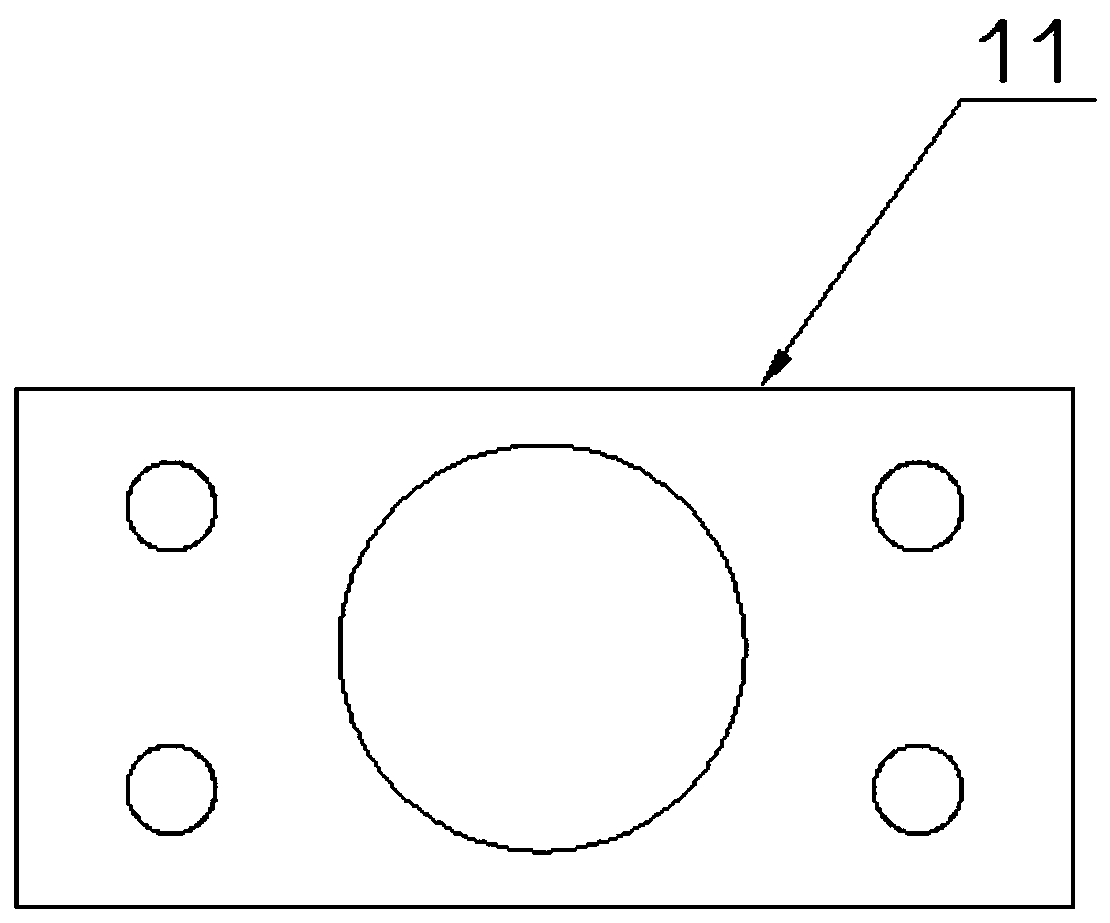

[0043] On the basis of Embodiment 1, the first pneumatic damping hole 5 and the second pneumatic damping hole 7 both include bolt installation grooves 16, and the bolt installation grooves 16 communicate with the cavity and the outside of the outer sleeve 1. The inner wall of the bolt mounting groove 16 is provided with an internal thread;

[0044]Also includes a bolt fastening mechanism 17, the bolt fastening mechanism 17 includes a bolt upper sleeve 171 and a bolt lower sleeve 172 that are mutually adapted, and the bolt upper sleeve 171 includes a head 1711 and a rod 1712 The head 1711 and the stem 1712 both include a second vent hole 1713, the second vent 1713 runs through the head 1711 and the stem 1712, and the outer wall of the stem 1712 of the bolt upper sleeve 171 is provided There are external threads, and a porous medium installation groove 10 is opened in the lower sleeve 172 of the bolt, and a third ventilation hole 18 is opened at the bottom of the porous medium i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com