A Air Leakage Prevention Technology by Leaving a Narrow Coal Pillar

A narrow coal pillar and anti-air leakage technology, which is applied in dust prevention, mining equipment, fire prevention, etc., can solve the problems of narrow coal pillar air leakage and other problems, and achieve the advantages of long manual operation safety distance, safe and reliable construction, and rapid increase in tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

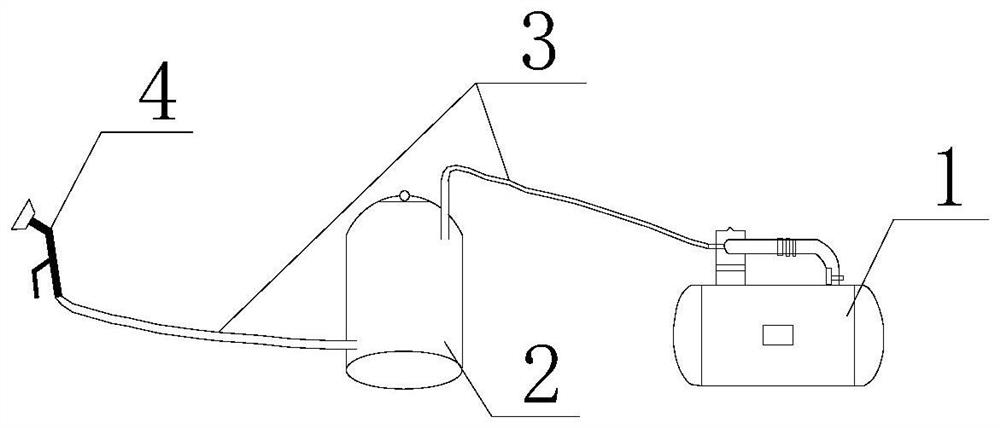

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

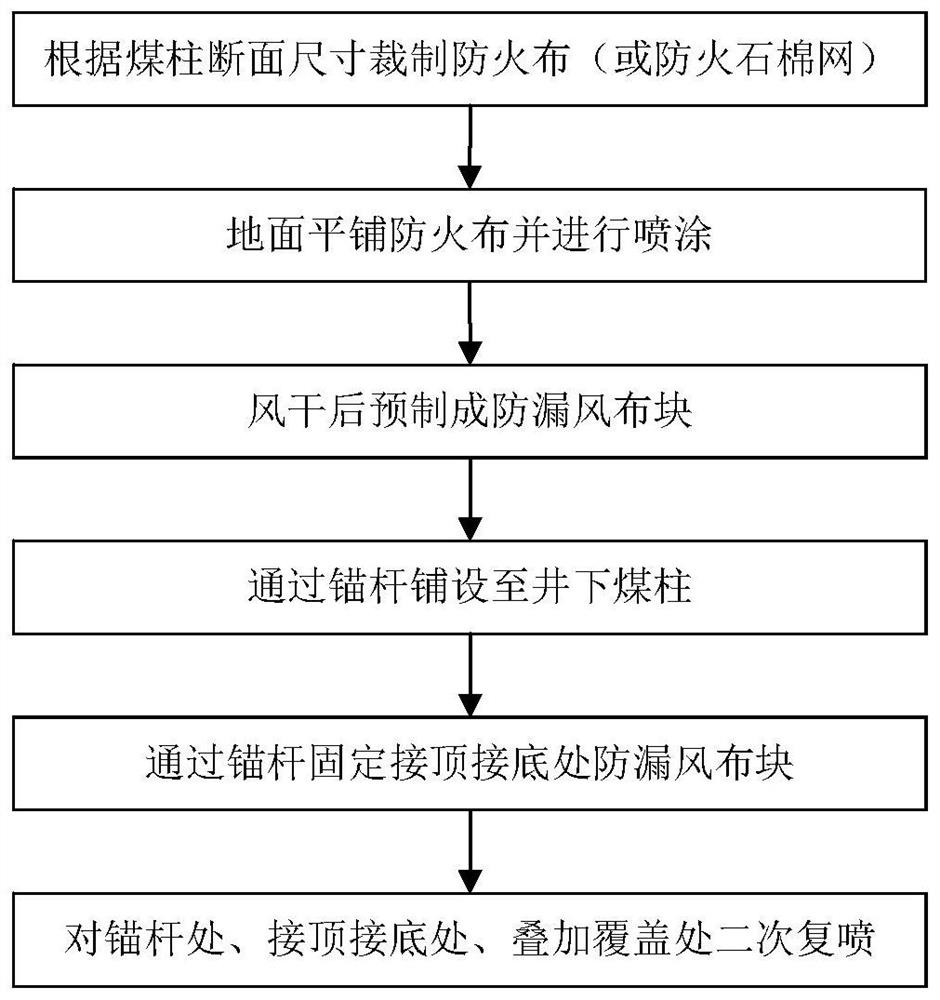

[0026] see figure 1 and figure 2 , an air leakage prevention process for leaving a narrow coal pillar, comprising the following steps:

[0027] Step 1: According to the cross-sectional size of the narrow coal pillars, cut a number of sheet fireproof materials, the sheet fireproof materials are fireproof cloth or fireproof asbestos net; the height of the cut sheet fireproof material is at least greater than that of the narrow coal pillars. Height 40cm.

[0028] Step 2: Lay the cut sheet-like fireproof material flat, and pre-spray to make air-leakage-proof prefabricated fireproof material;

[0029] Step 3: After the anti-leakage prefabricated fireproof material is air-dried and formed, it is laid on the narrow coal pillar through the anchor rod. The longitudinal direction is required to be more than 20cm above and below, and the remaining part is fixed on the top an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com