Method and device for extracting mercury forms in grain and application thereof

An extraction device and extraction method technology, applied in the field of chemical separation, can solve the problems of long pretreatment time, human and environmental hazards, and inability to detect mercury forms, so as to shorten the extraction time, reduce the extraction time, and avoid the damage of mercury elements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1 Extraction device for rapid extraction of mercury forms in grains

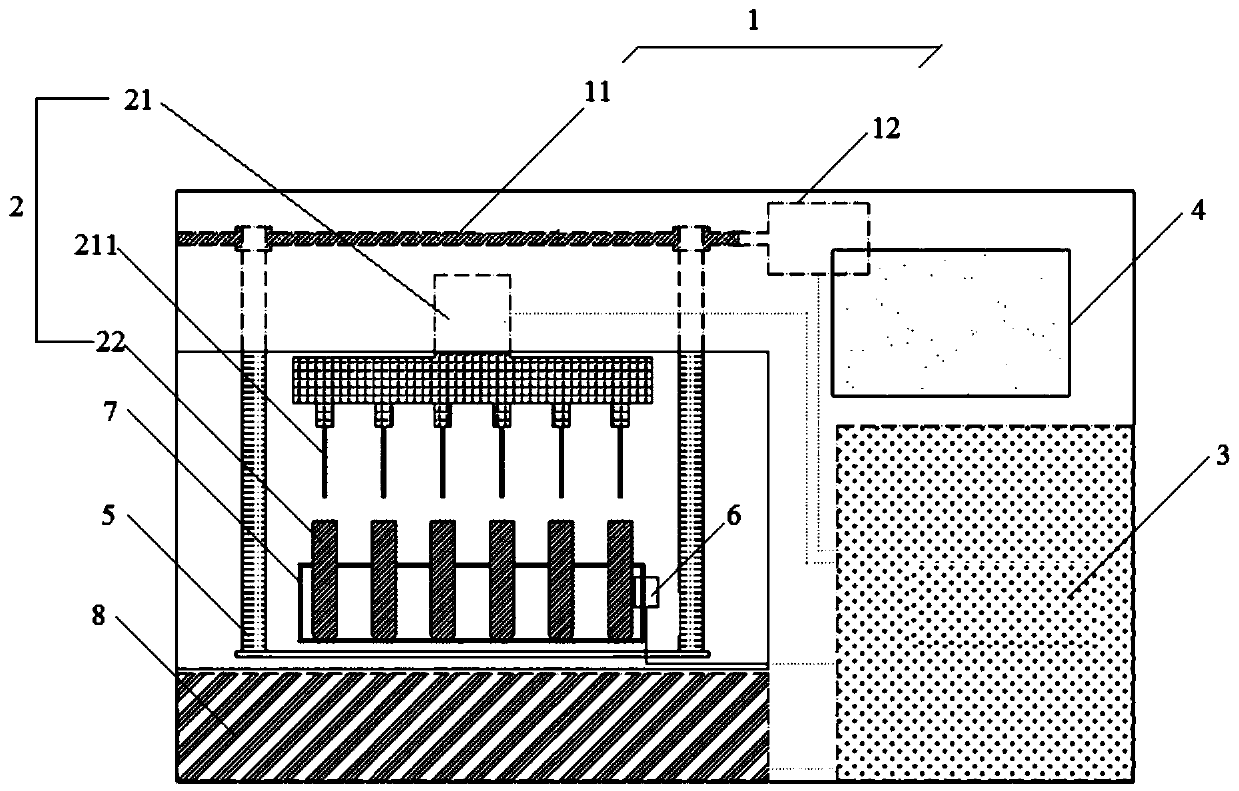

[0059] Such as figure 1 As shown, the extraction device for quickly extracting the form of mercury in grains of the present invention includes a drive unit 1, an ultrasonic unit 2, an electric control unit 3 and a display unit 4, the drive unit 1 is connected to the ultrasonic unit 2 through a belt 5, and the drive unit 1 , the ultrasonic unit 2, and the display unit 4 are respectively connected to the electric control unit 3;

[0060] The drive unit 1 includes a drive shaft 11 and a motor 12, the drive shaft 11 is directly connected to the motor 12, and the motor 12 is powered by a battery 8;

[0061] The ultrasonic unit 2 includes an ultrasonic head 21 and a sample container centrifuge tube 22. The ultrasonic head 21 includes six ultrasonic horns 211, which are respectively placed corresponding to the six sample containers 22, and the sample containers 22 are placed on the container holder ...

Embodiment 2

[0064] Embodiment 2 detects the mercury form in the sample

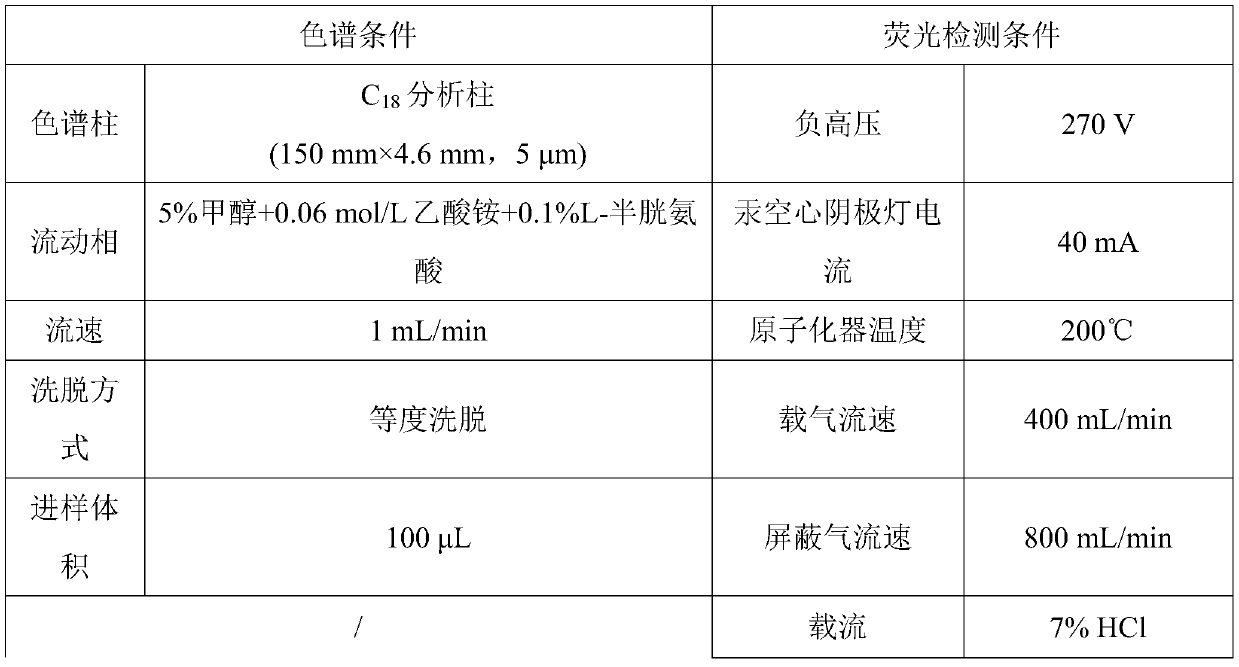

[0065] Adopt liquid chromatography-atomic fluorescence spectrometry to detect inorganic mercury and methylmercury in the liquid to be tested obtained in Example 1, and set a control group, specifically as follows:

[0066] The control group weighed 0.5g of the same brown rice sample as in Example 1, extracted according to the pretreatment method specified in GB5009.17-2014 "National Food Safety Standard Food Determination of Total Mercury and Organic Mercury", and added 5mL of 5mol / L hydrochloric acid, left overnight; Ultrasonic water bath extraction at room temperature for 60min, shaking several times during the period; 5. Add 0.1mL of 10 g / L L-cysteine solution, and finally dilute to 5mL with ultrapure water; filter through a 0.45μm organic filter membrane before testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com