Method for determining biodegradation degree of crude oil

A technology of biodegradation and crude oil, applied in the direction of measuring devices, instruments, and material analysis through electromagnetic means, can solve the problems of low dependence and inaccurate judgment, and achieve the effect of accurate judgment and low dependence on personal experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

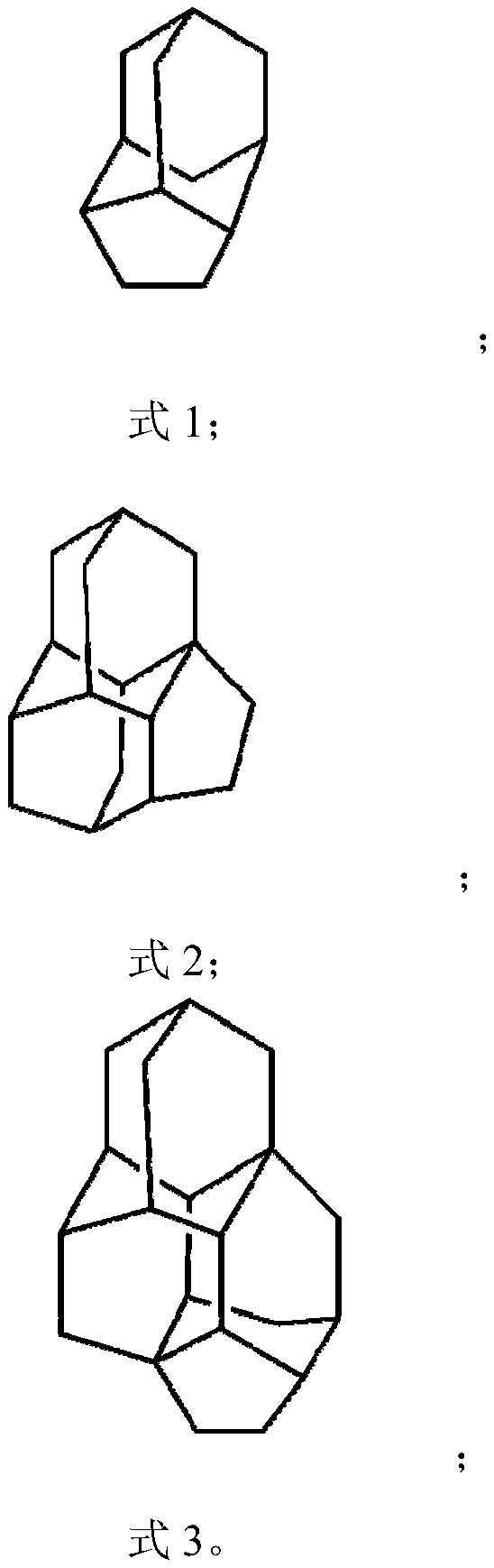

[0032] This embodiment provides a method for determining the degree of biodegradation of crude oil using ethyl noradamantane compounds, wherein the method includes the following specific steps:

[0033] 1) Take 200 mg of condensate oil A with a viscosity of 1.65 mPa·s, add 40 μL of 0.5 μg / μL d16-adamantane to the condensate oil A, then add dichloromethane to 1.5 mL, mix well and set aside;

[0034] 2) Using a comprehensive two-dimensional gas chromatography-time-of-flight mass spectrometer (GC×GC-TOF MS) to detect the mixture to identify and quantitatively analyze the ethyl noradamantane compounds in the condensate A ;

[0035] Obtain the absolute content of unsubstituted single cage ethyl noradamantane, unsubstituted double cage ethyl noradamantane, n-dodecane and n-hexadecane respectively;

[0036] 3) According to the identification and quantitative analysis results obtained in step 2), calculate the content ratio of unsubstituted single cage ethyl noradamantane and unsubst...

Embodiment 2

[0040] This embodiment provides a method for determining the degree of biodegradation of crude oil using ethyl noradamantane compounds, wherein the method includes the following specific steps:

[0041]1) Take 200 mg of condensate oil B with a viscosity of 2.65 mPa·s, add 40 μL of 0.5 μg / μL d16-adamantane to the condensate oil B, then add dichloromethane to 1.5 mL, mix well and set aside;

[0042] 2) Using a comprehensive two-dimensional gas chromatography-time-of-flight mass spectrometer (GC×GC-TOF MS) to detect the mixture to identify and quantitatively analyze the ethyl noradamantane compounds in the condensate B ;

[0043] Obtain the absolute content of unsubstituted single cage ethyl noradamantane, unsubstituted double cage ethyl noradamantane, n-dodecane and n-hexadecane respectively;

[0044] 3) According to the identification and quantitative analysis results obtained in step 2), calculate the content ratio of unsubstituted single cage ethyl noradamantane and unsubsti...

Embodiment 3

[0048] This embodiment provides a method for determining the degree of biodegradation of crude oil using ethyl noradamantane compounds, wherein the method includes the following specific steps:

[0049] 1) Take 200 mg of crude oil C with a viscosity of 5.56 mPa·s, add 40 μL of 0.5 μg / μL d16-adamantane to the normal oil C, then add dichloromethane to 1.5 mL, mix well and set aside;

[0050] 2) Using a comprehensive two-dimensional gas chromatography-time-of-flight mass spectrometer (GC×GC-TOF MS) to detect the mixed solution, so as to identify and quantitatively analyze the ethyl noradamantane compounds in the normal oil C;

[0051] Obtain the absolute content of unsubstituted single cage ethyl noradamantane, unsubstituted double cage ethyl noradamantane, n-dodecane and n-hexadecane respectively;

[0052] 3) According to the identification and quantitative analysis results obtained in step 2), calculate the content ratio of unsubstituted single cage ethyl noradamantane and unsu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com