Ethirimol emulsion in water and preparation method thereof

A pyrithrimol emulsion in water and the technology of pyrithrimol, applied in the field of pesticides, can solve the problems of poor drug efficacy and unstable preparations, and achieve the effects of excellent drug efficacy, excellent stability, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Proportioning 5% pyrimethol water emulsion according to the following percentage by weight:

[0038] Acetrimol 5%

[0039] N-n-octylpyrrolidone 5%

[0040] Tristyrylphenol ethoxylate phosphate 3%

[0041] Propylene Glycol 4%

[0042] water to 100%

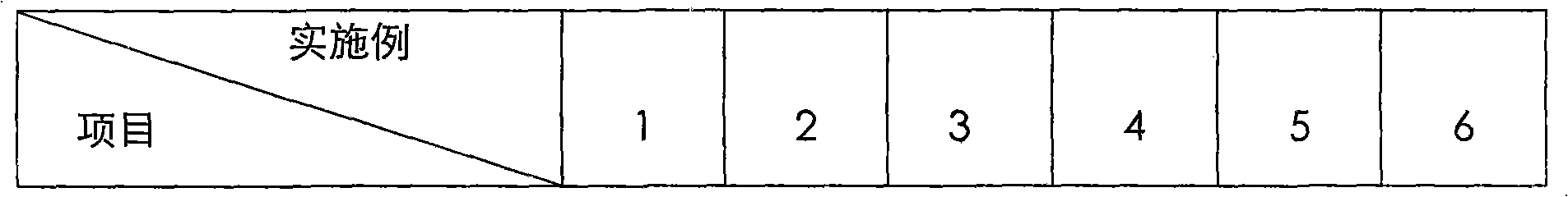

[0043] First add pyrithrimol and N-octylpyrrolidone into the reaction kettle, and completely dissolve pyrithrimol in the solvent under mechanical stirring to obtain the oil phase; tristyrylphenol polyoxyethylene ether phosphate, Put water and propylene glycol into a high-shear kettle, stir to obtain a water phase, add the oil phase evenly into the water phase under a shear of 1000 rpm, and shear for 45 minutes to make it an average particle size of 0.21 microns, Uniform emulsion. The test results of the main technical indicators of the emulsion are shown in Table 1.

Embodiment 2

[0045] Proportioning 15% pyrimethol water emulsion according to the following percentage by weight:

[0046] Acetrimol 15%

[0047] N-Dodecylpyrrolidone 8%

[0048] Castor Oil Ethoxylates 5%

[0049] Propylene Glycol 4%

[0050] water to 100%

[0051] First add pyrithrimol and N-n-dodecylpyrrolidone into the reaction kettle, and completely dissolve pyrithrimol in the solvent under mechanical stirring to obtain an oil phase; mix castor oil polyoxyethylene ether, water and propylene glycol Put it into a high-shear kettle, stir, and prepare the water phase. Add the oil phase into the water phase evenly under the shear of 2000 rpm, and shear for 50 minutes to make it into a uniform emulsion with an average particle size of 0.23 microns. liquid. The test results of the main technical indicators of the emulsion are shown in Table 1.

Embodiment 3

[0053] Proportioning 30% pyrimethol in water emulsion according to the following percentage by weight:

[0054] Acetrimol 30%

[0055] Solvesso200 10%

[0056] Phosphate ester of EO / PO block copolymer 5%

[0057] Propylene Glycol 4%

[0058] water to 100%

[0059] First add pyrithrimol and Solvesso200 into the high-shear kettle and stir to make pyrithrimol completely dissolve in the solvent to obtain the oil phase; mix the phosphate ester of EO / PO block copolymer, water and propylene glycol to form a For the water phase, add the water phase evenly into the oil phase under a shear of 3000 rpm, and shear for 60 minutes to make it into a uniform emulsion with an average particle size of 0.26 microns. The test results of the main technical indicators of the emulsion are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com