Method for preparing surface-active onion-like carbon nanospheres based on vapor deposition

An onion-like carbon and surface-active technology, which is applied in the fields of nanotechnology, nanotechnology, and nanotechnology for materials and surface science, can solve the problem of low surface activity of onion-like carbon nanospheres, and achieve good surface activity and thermal stability. Good stability, thermal stability and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

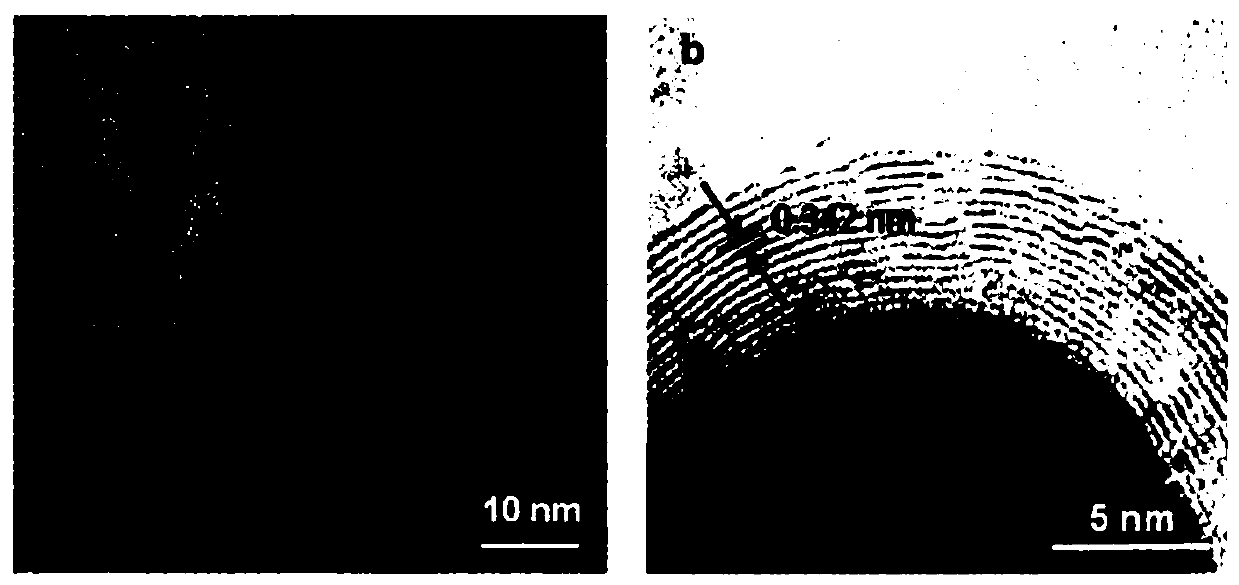

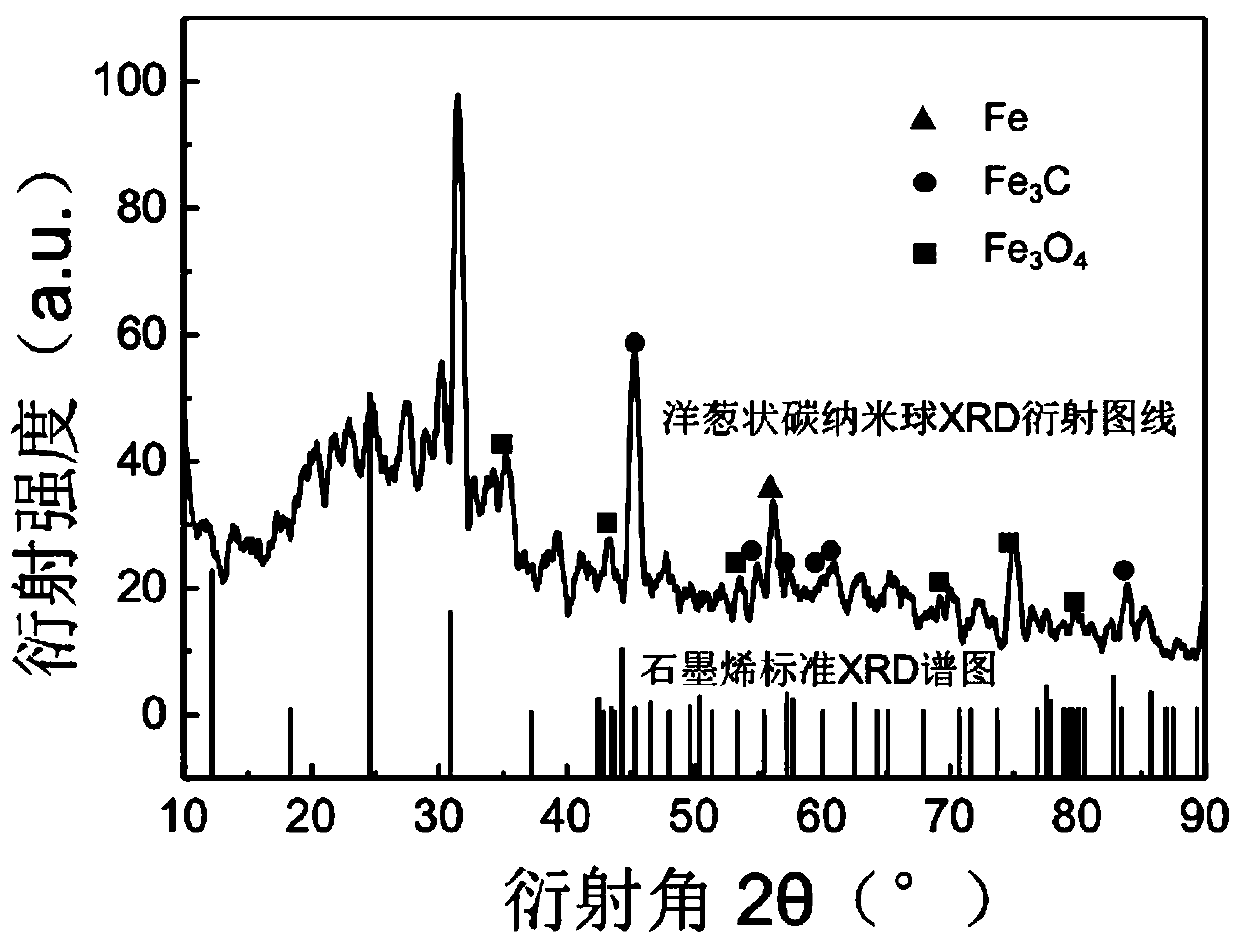

Embodiment 1

[0025] Measure 2.5mL (1.9g) of n-dodecane, weigh 0.1g of ferrocene, put them together in 5mL of deionized water, mix them evenly by ultrasonic, and put them into a quartz boat. Place the quartz boat in a horizontal resistance furnace, and place a glass slide at the rear of the furnace tube to collect the product.

[0026] Use argon as the carrier gas, adjust the flow rate of the carrier gas to 30mL / min to exhaust the air in the furnace tube and start heating; when the temperature rises from room temperature to 100°C at a rate of 10°C / min, reduce the flow rate of the carrier gas to 3mL / min min; continue to heat up to 700°C at the same heating rate, adjust the carrier gas flow rate to 5mL / min, and react for 20 minutes, so that the vaporized n-dodecane is fully carbonized in the high-temperature reaction zone and deposited on the pre-placed glass slide in the furnace tube .

[0027] After the reaction, the flow rate of the carrier gas was adjusted to 10 mL / min, and the glass sli...

Embodiment 2

[0034] Measure 1.5mL (1.1g) of n-dodecane and 0.1g of ferrocene, put them together in 5mL of deionized water, mix them evenly by ultrasonic, and put them into a quartz boat. Place the quartz boat in a horizontal resistance furnace, and place a glass slide at the rear of the furnace tube to collect the product.

[0035] The carbonization reaction was carried out according to the conditions of Example 1, and surface-active onion-like carbon nanospheres with a particle diameter of about 30 nm were prepared.

Embodiment 3

[0037] Measure 2.5mL (1.9g) of n-dodecane and 0.1g of ferrocene, put them together in 10mL of deionized water, mix them evenly by ultrasonic, and put them into a quartz boat. Place the quartz boat in a horizontal resistance furnace, and place a glass slide at the rear of the furnace tube to collect the product.

[0038] The carbonization reaction was carried out according to the conditions of Example 1, and surface-active onion-like carbon nanospheres with a particle diameter of about 30 nm were prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com