Macroporous phenolic resin, preparation method thereof and application thereof in adsorption of 5-hydroxymethyl furfural

A technology for adsorption and separation of phenolic resins, applied in selective adsorption, chemical instruments and methods, and other chemical processes. Production and other issues, to achieve the effect of easy regeneration and recycling, easy regeneration and recycling, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

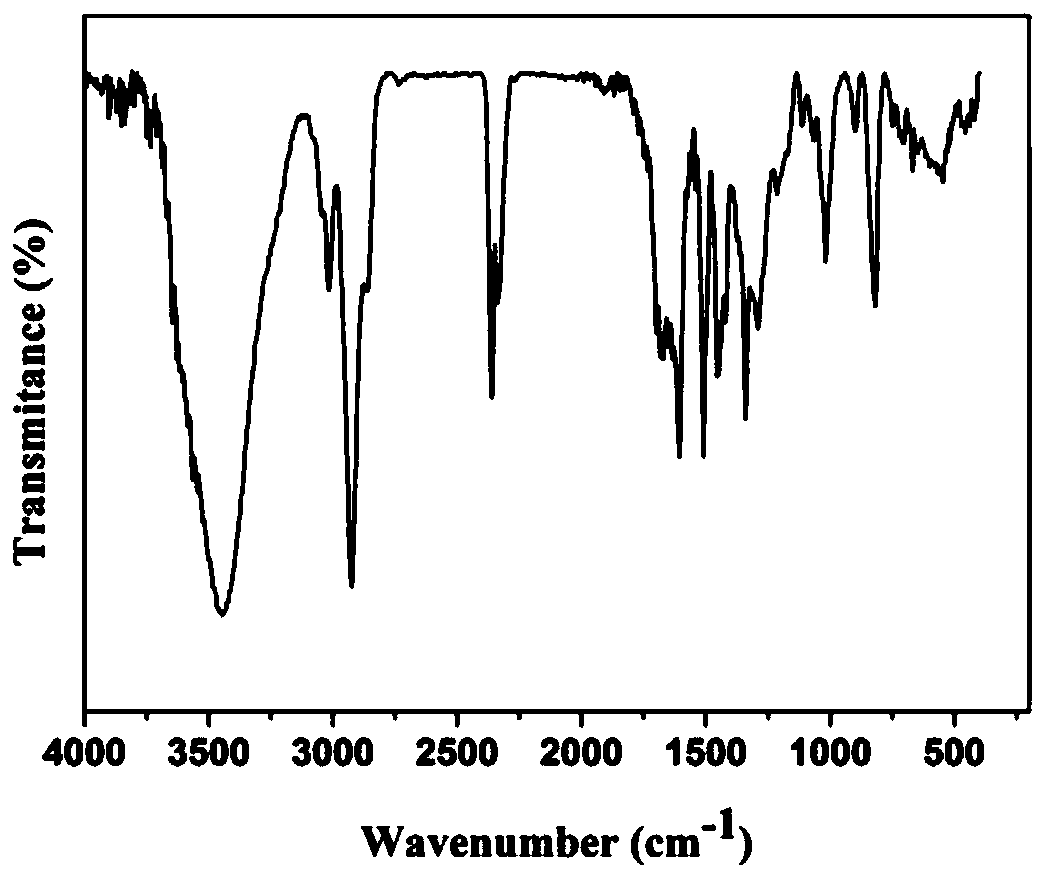

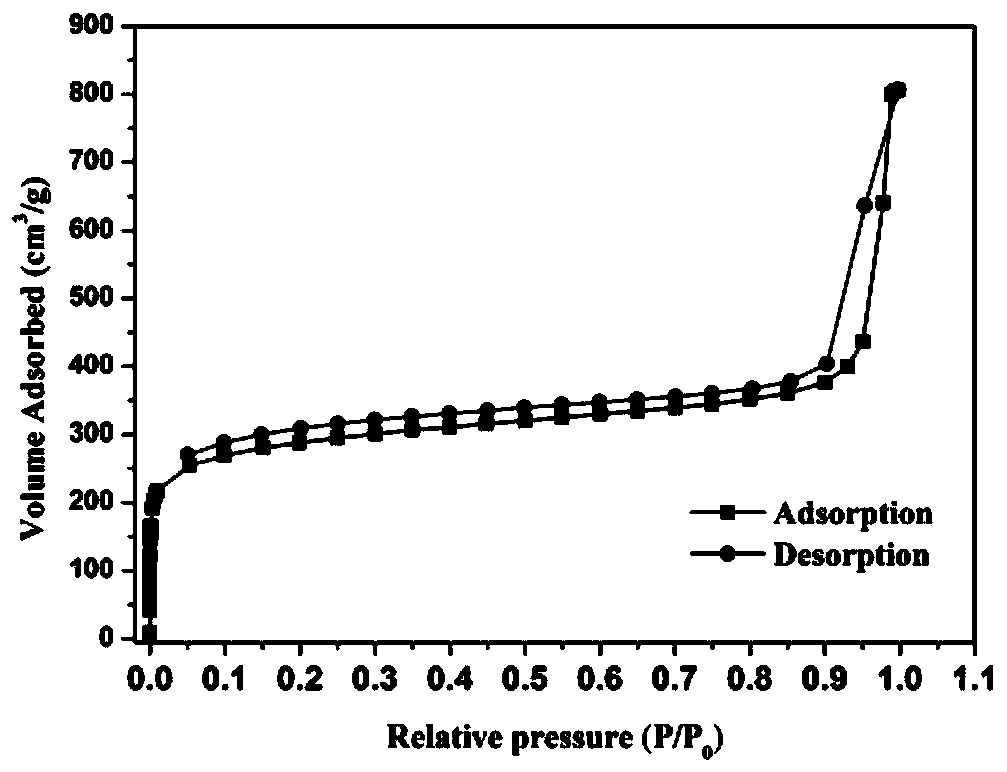

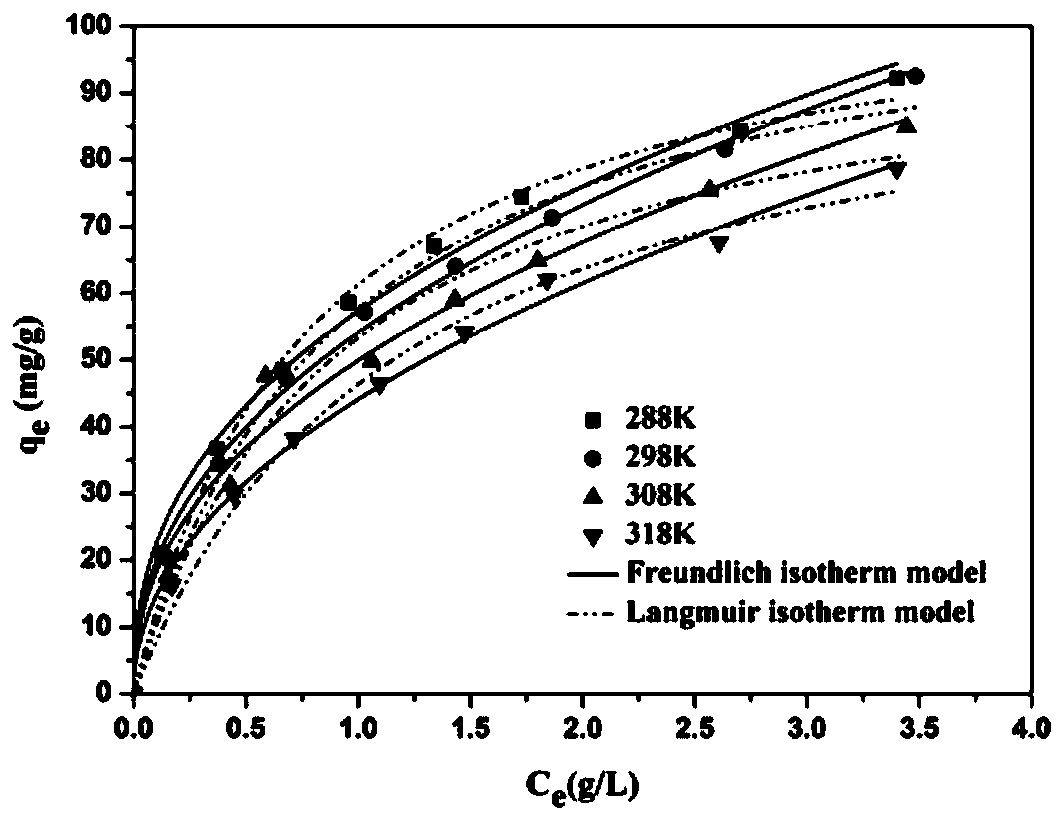

[0039] A kind of macroporous phenolic resin, the BET specific surface area of macroporous phenolic resin is 1050m 2 / g, the pore volume is 1.25cm 3 / g, the average pore diameter is 5.0nm,

[0040] The preparation method of macroporous phenolic resin comprises the steps:

[0041] (1) Slurry

[0042] Add 28g of phenol, 60g of 37% formaldehyde, 150g of ethylene glycol, and 3.0g of NaOH into a 500mL three-necked flask equipped with a thermometer, a stirring device and a condenser, stir until the solid dissolves, raise the temperature to 77°C, and cool down to room temperature to form a slurry after 2 hours of reaction , wherein the mol ratio of phenolic monomers to formaldehyde is 1:2.5, the mol ratio of phenolic monomers to NaOH is 1:0.25, the total mass of phenolic monomers and formaldehyde: the mass ratio of porogen is 1:3;

[0043] (2) into a ball

[0044] Add 480g of turbine oil and 0.375wt% gSpan-80 into a 1000mL three-necked flask equipped with a thermometer, a stirri...

Embodiment 2

[0048] Same as Example 1, except that the molar ratio of phenolic monomers to formaldehyde is 1:3.5, the molar ratio of phenolic monomers to NaOH is 1:0.25, the total mass of phenolic monomers and formaldehyde: porogen The mass ratio is 1:3.

Embodiment 3

[0050] Same as Example 1, except that the molar ratio of phenolic monomers to formaldehyde is 1:10, the molar ratio of phenolic monomers to NaOH is 1:5, and the total mass of phenolic monomers and formaldehyde: porogen The mass ratio is 1:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com