Cellulose nanofibers and preparation method thereof

A nanofiber and cellulose technology, applied in the field of cellulose nanofiber and its preparation, can solve the problems of long cycle and strict environmental conditions, high requirements for machinery and equipment, high energy consumption, etc., and achieve high modifiability, excellent Mechanical properties, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a cellulose nanofiber and a preparation method thereof.

[0036] Preparation method of cellulose nanofibers

[0037] The preparation method of cellulose nanofibers comprises the following steps:

[0038] Step 1): disperse the cellulose in the first organic solvent and configure it into a cellulose dispersion;

[0039] Step 2): adding lithium hydroxide to the cellulose dispersion obtained in step 1) to fully swell the cellulose;

[0040] Step 3): react the fully swollen cellulose obtained in step 2) with an acid anhydride, wash the reaction solution, and obtain a cellulose reaction product;

[0041] Step 4): Disperse the cellulose reaction product obtained in step 3) in an alkaline aqueous solution, centrifuge, and dialyze the supernatant to obtain a suspension containing cellulose nanofibers.

[0042] In one or more embodiments of the present invention, in the step 1), the first organic solvent is dimethyl sulfoxide.

[0043] In one or more em...

Embodiment 1

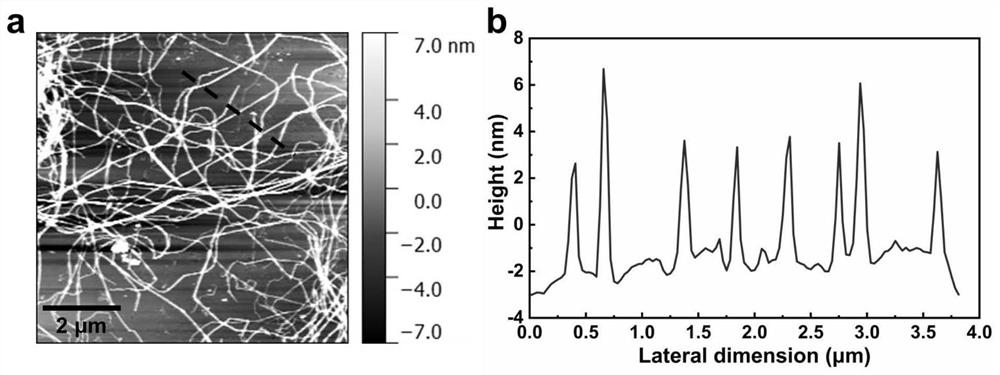

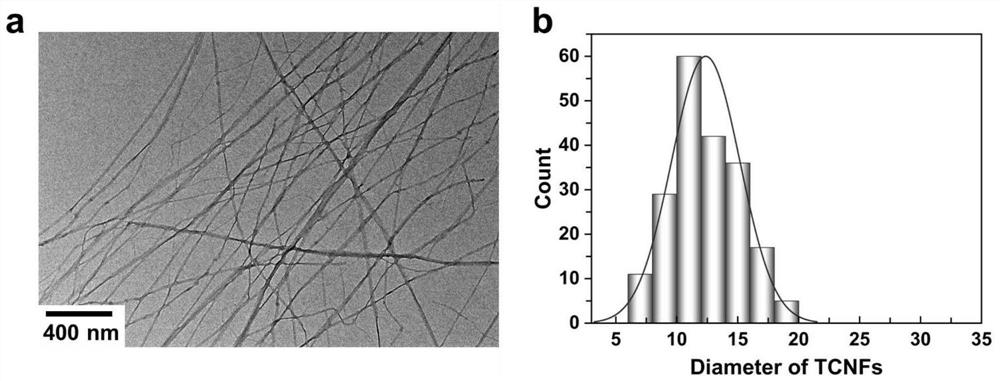

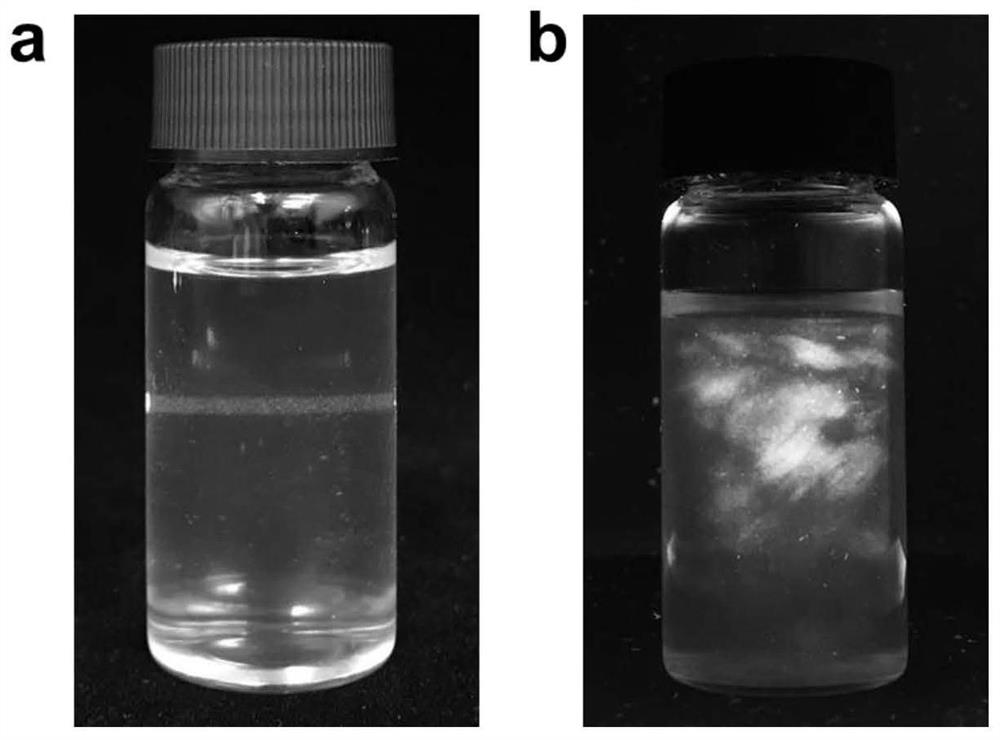

[0056] Under anhydrous conditions, the ascidian cellulose raw material was dispersed in dimethyl sulfoxide to form a 0.5wt% dispersion liquid, lithium hydroxide was added to fully swell the cellulose, and the mass ratio of the added lithium hydroxide to cellulose was 1 : 5. Add succinic anhydride in a molar ratio of 1:1 (acid anhydride: anhydroglucose unit), stir magnetically, and react for 1 h. The reaction temperature is controlled to 15 °C. After the reaction is complete, dimethyl sulfoxide and ethanol are used for centrifugal washing in turn to obtain cellulose. The reaction product, the cellulose reaction product was dispersed in an aqueous lithium hydroxide solution with pH=8, and dialyzed for three days to obtain a suspension containing cellulose nanofibers. The yield of the obtained cellulose nanofibers was about 10%, and the average diameter was about 10%. It is 12 nm, the height is between 4 and 8 nm, the length is between 10 and 15 μm, and the aspect ratio is betwee...

Embodiment 2

[0058] Under anhydrous conditions, the ascidian cellulose raw material was dispersed in dimethyl sulfoxide to form a 1wt% dispersion liquid, lithium hydroxide was added to fully swell the cellulose, and the mass ratio of the added lithium hydroxide to the cellulose was 1: 10. Add phthalic anhydride in a molar ratio of 3:1 (acid anhydride: anhydroglucose unit), stir magnetically, react for 12 hours, and control the reaction temperature to 25 °C. The reaction product, the cellulose reaction product was dispersed in a lithium hydroxide aqueous solution with pH=11, and dialyzed for three days to obtain a suspension containing cellulose nanofibers. The yield of the obtained cellulose nanofibers was about 45%, and the average diameter was about It is 12 nm, the height is between 4-8 nm, the length is between 10 and 15 μm, and the aspect ratio is between 800 and 1250.

[0059] figure 1 is the atomic force microscope image of the ascidian cellulose nanofibers obtained by the prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com