Machine-made sand conditioner for concrete, concrete and preparation method thereof

A technology of sand conditioner and concrete, which is applied in the field of building materials, can solve the problems that machine-made sand cannot be used, and achieve the effect of improving 2h expansion degree, simple composition, and improving 2h slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

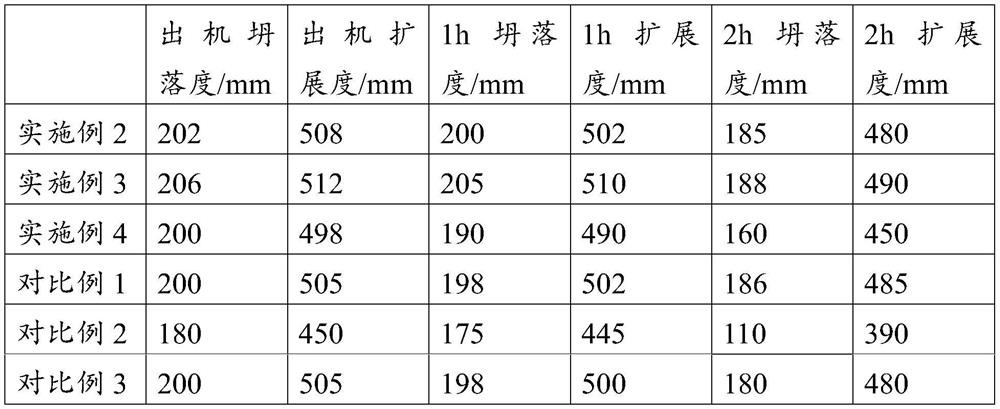

Examples

preparation example Construction

[0055] In some embodiments, the preparation method of the admixture includes: ball-milling zeolite powder for 30min-1h, adding pumice powder, ball-milling for 1-2h; finally adding fly ash, ball-milling and mixing for 30min-45min. Get the admixture. It is ensured that the pores of the pumice powder can be filled with zeolite powder, the proportion of the pumice powder is increased, the dispersibility of the pumice powder in the concrete is improved, and the pumice powder can be fully contacted and reacted with the cement to improve the performance of the concrete.

[0056] In some embodiments, the weight ratio of admixture to cementitious material is 0.5 to 0.8:1. Reduce cement usage.

[0057] Optionally, the admixture to cementitious material weight ratio is 0.65:1.

[0058] In the embodiment of the present disclosure, the proportion of each component in the concrete can be based on the existing conventional concrete, or can be specifically prepared according to the actual s...

Embodiment 1

[0064] The machine-made sand conditioner, in parts by weight, includes: 40 parts of polycarboxylic acid mother liquor, 20 parts of diethanol monoisopropanolamine, 2 parts of triisopropanolamine, 20 parts of glycerin and 2 parts of sodium sulfate; 916 parts of water.

[0065] The machine-made sand conditioner in Example 1 includes, by weight percentage: 4% of polycarboxylic acid mother liquor, 2% of diethanol monoisopropanolamine, 0.2% of triisopropanolamine, 2% of glycerin and 0.2% of sodium sulfate .

Embodiment 2

[0067] Concrete I, in parts by weight, includes: 180 parts of cementitious materials, 850 parts of coarse aggregates, 1050 parts of fine aggregates, 6.5 parts of water reducer, 2.5 parts of machine-made sand conditioner, 120 parts of admixtures and 160 parts of water.

[0068] Wherein, the artificial sand conditioner of Example 1 was adopted as the artificial sand conditioner. The cementitious material is cement. The coarse aggregate is 1 to 3 stones. The water reducing agent adopts polycarboxylate water reducing agent. The fine aggregate is machine-made sand, wherein the content of stone powder with a particle size of less than 75 μm in the machine-made sand is 20% to 25%.

[0069] The admixture includes fly ash (particle size is not limited), pumice powder (particle size is 1-5 μm) and zeolite powder (particle size is 10-200nm); wherein, the weight ratio of fly ash to pumice powder is 1: 0.6; the weight ratio of fly ash to zeolite powder is 1:0.6. It was prepared by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com