Vibratory potato harvester

A potato and harvester technology, which is applied to digging harvesters, harvesters, excavators, etc., can solve the problems of incomplete digging, low adaptability, and high loss rate, so as to reduce manpower and material resources, improve harvesting efficiency, and manufacture low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

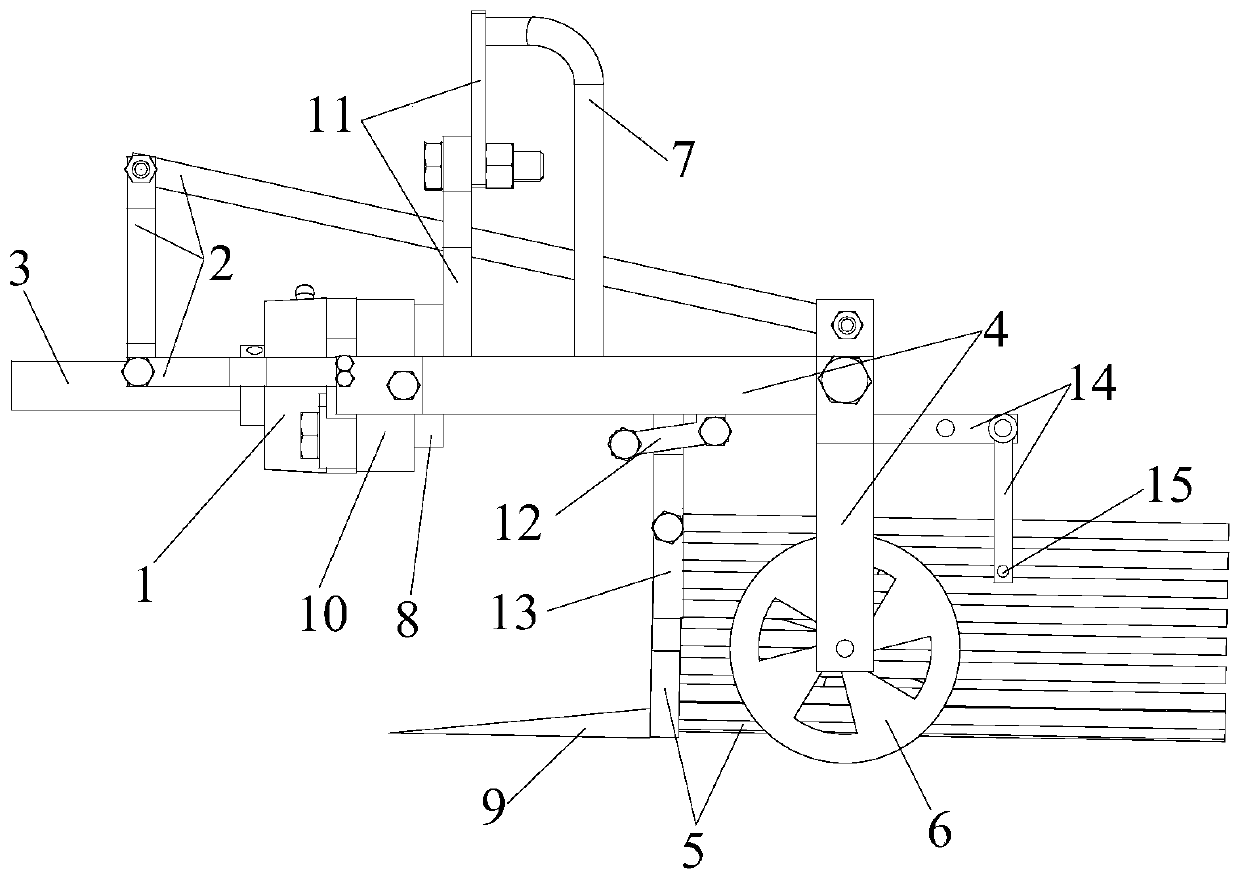

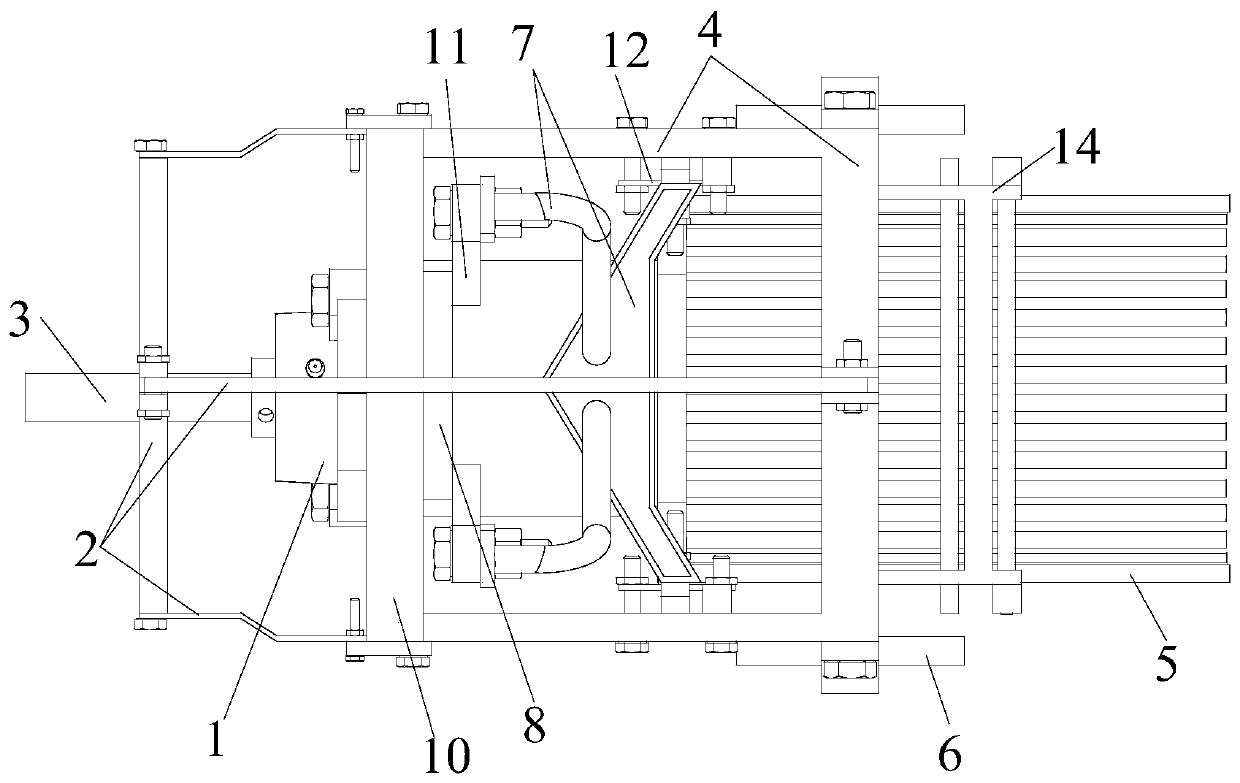

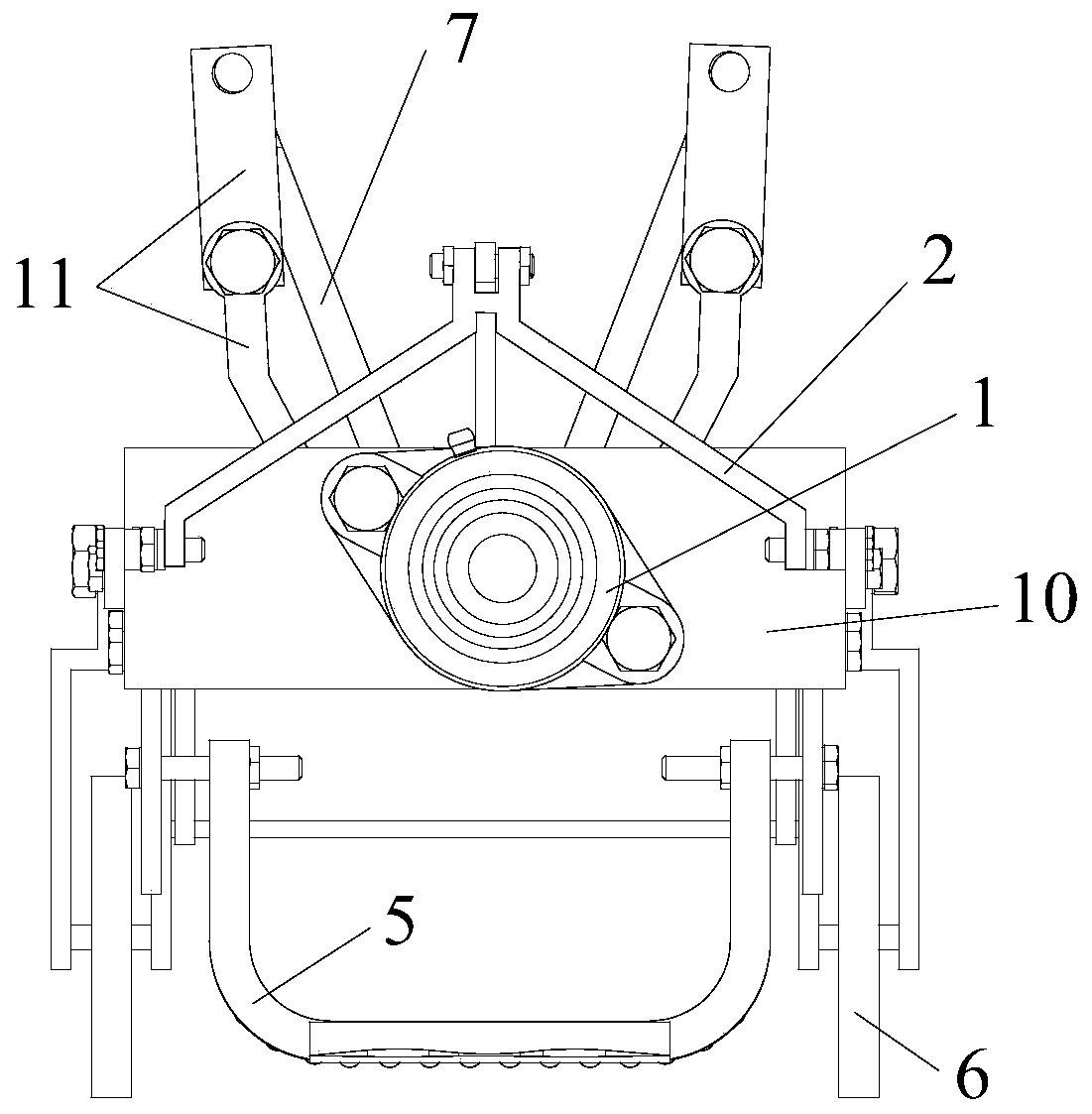

[0035] Figure 1-Figure 8 Some embodiments according to the invention are shown.

[0036] Such as figure 1 , 2 As shown, a vibrating potato harvester mainly includes parts such as frame 4, traction frame 2, vibrating separator 5, digging shovel 9, drive shaft 3, walking wheel 6, vibrating frame 7, wherein, frame 4 passes through The bolt fastener is fixedly connected with the traction frame 2, and the front end of the traction frame 2 is connected with the tractor for dragging the whole harvester.

[0037] Specifically, as figure 1 , 2 As shown, the traveling wheel 6 is installed on the frame 4, and is positioned at the lower end of the second half of the frame 4. The front end of the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com