Multi-functional stone mill rice noodle roll machine

A multi-functional, sausage powder machine technology, applied in the direction of cocoa, grain processing, food forming, etc., can solve the problems of high use cost, waste of heat energy, delay time, etc., to improve the utilization rate of the whole machine, reduce the use cost, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

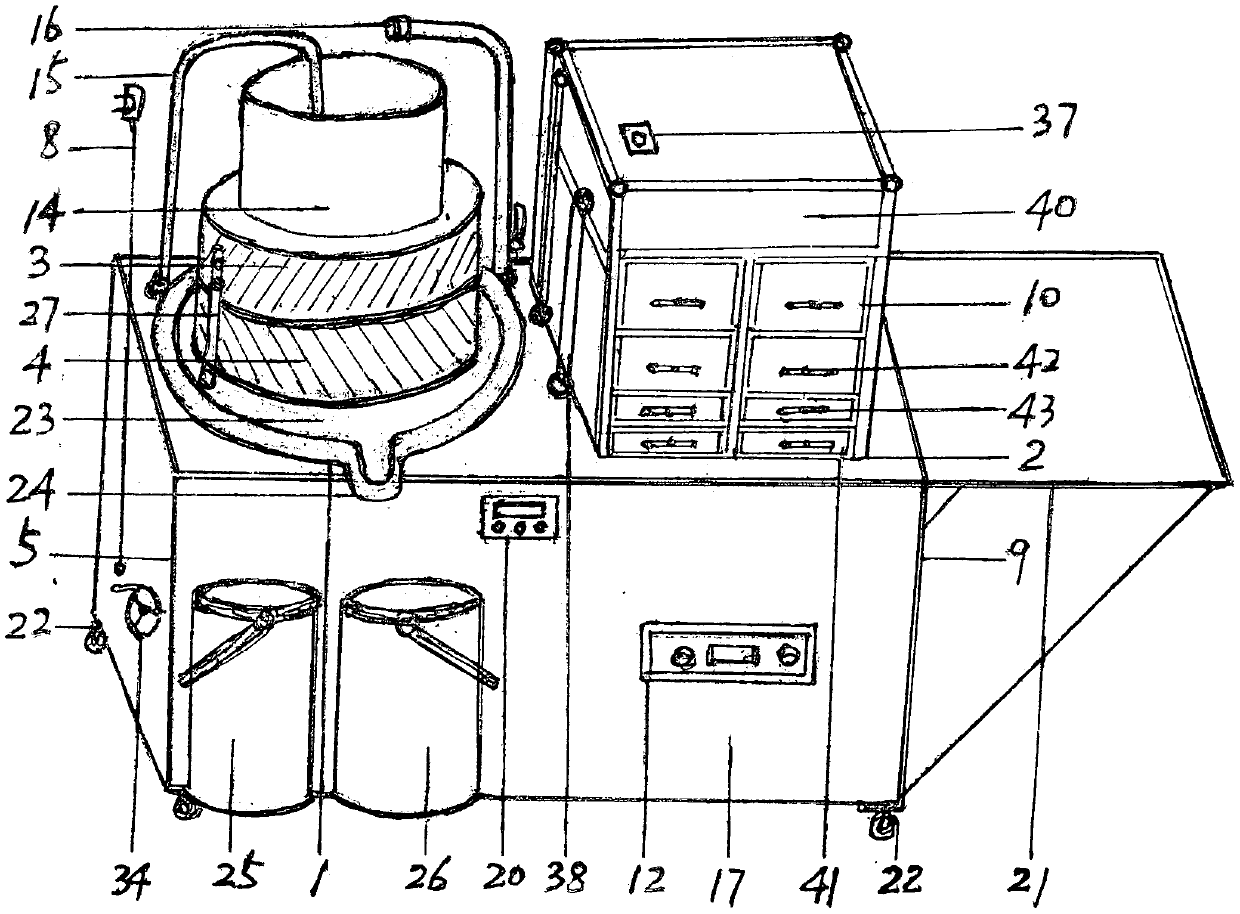

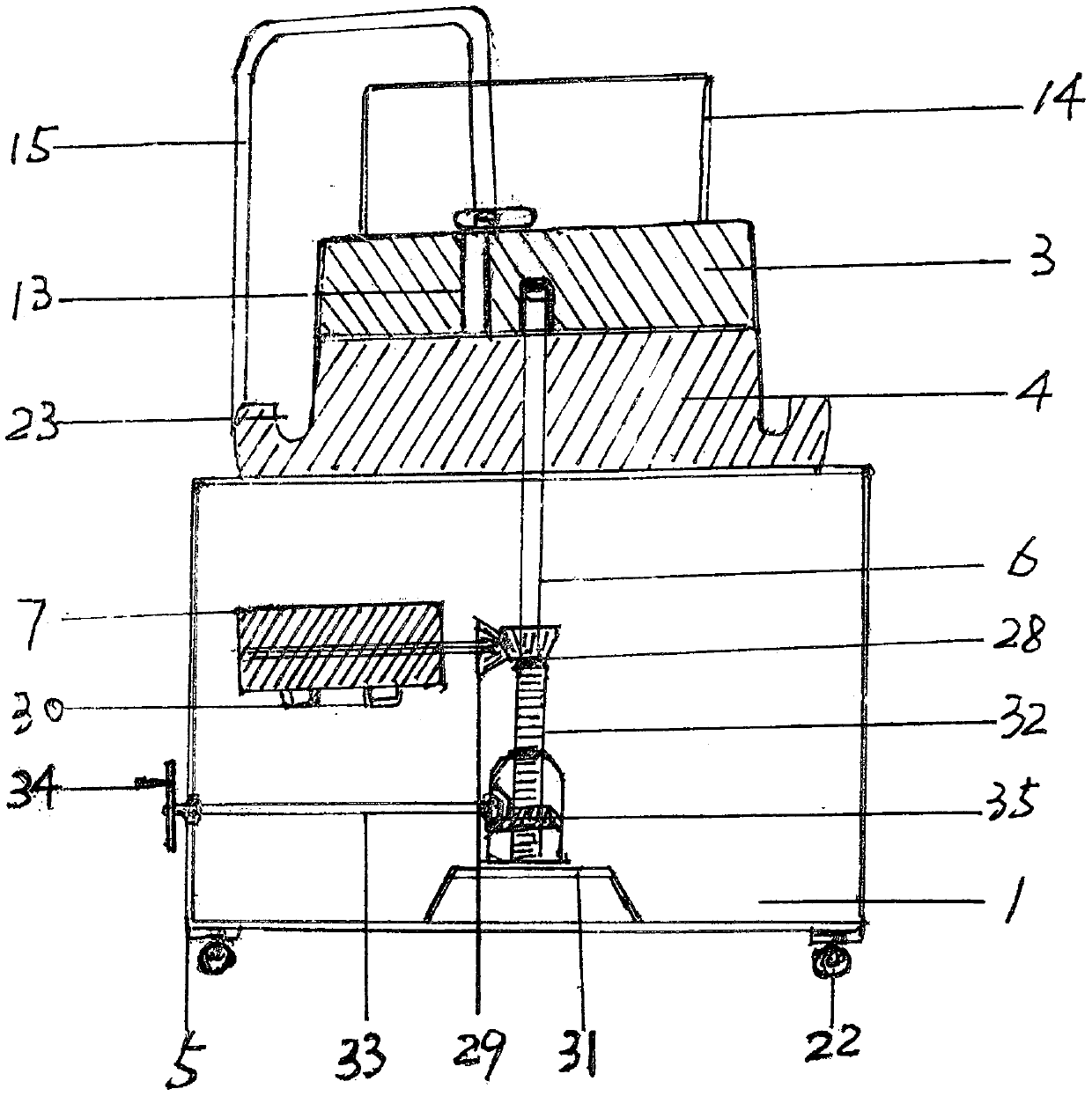

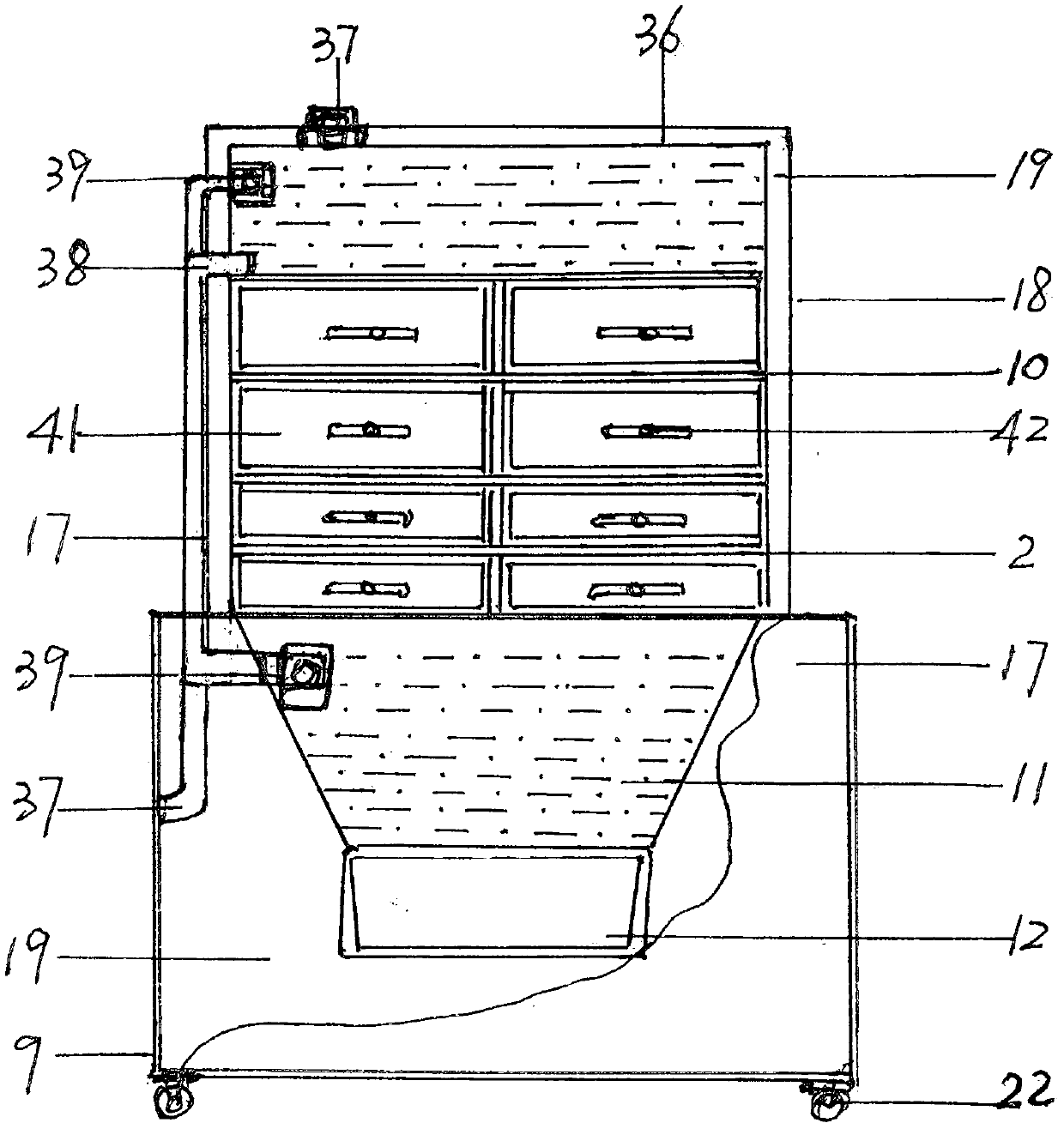

[0019] Embodiment 1: as figure 1 , figure 2 , image 3 The shown multifunctional stone-milled intestine powder machine comprises a stone-milling device 1 and a steamer device 2. The stone-milling device 1 is controlled by an upper millstone 3, a lower millstone 4, a frame 5, a drive shaft 6, a drive motor 7, Panel 20, external power supply 8 is formed, and its steamer device 2 is made up of body 9, steamer 10, cooking pot 11, heating stove 12, described stone mill device 1 and steamer device 2 are integrated, and the top of its upper grinding disc 3 is arranged Feed hole 13 and charging cylinder 14 are arranged, and special-shaped stirring rod 15 and faucet 16 with running water pipe are arranged on the inside of charging cylinder 14 and the top of frame 5, and described steamer 10 is set in the middle of body 5 Above the cooking pot 11, the periphery has a coaming 17, a frame 18, a thermal insulation layer 19, and eight metal steaming boxes with a height of 5-20 centimeter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com