A semiconductor electroplating machine

An electroplating machine and semiconductor technology, applied in semiconductor devices, circuits, electrolytic components, etc., can solve the problems of easy leakage of odors and affect the health of workers, and achieve the effect of improving the rate of waste gas treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

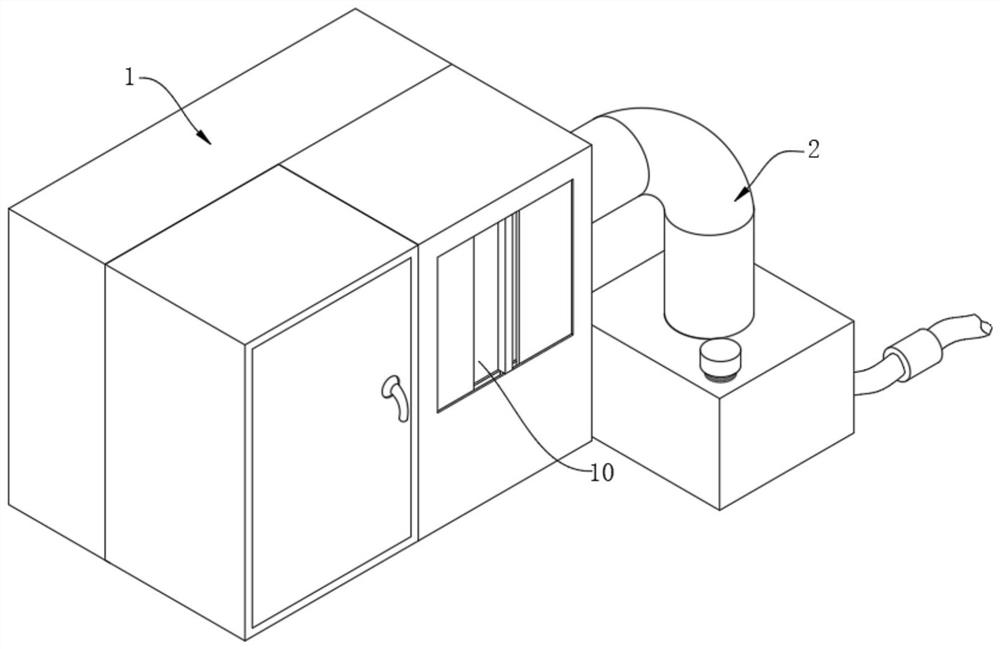

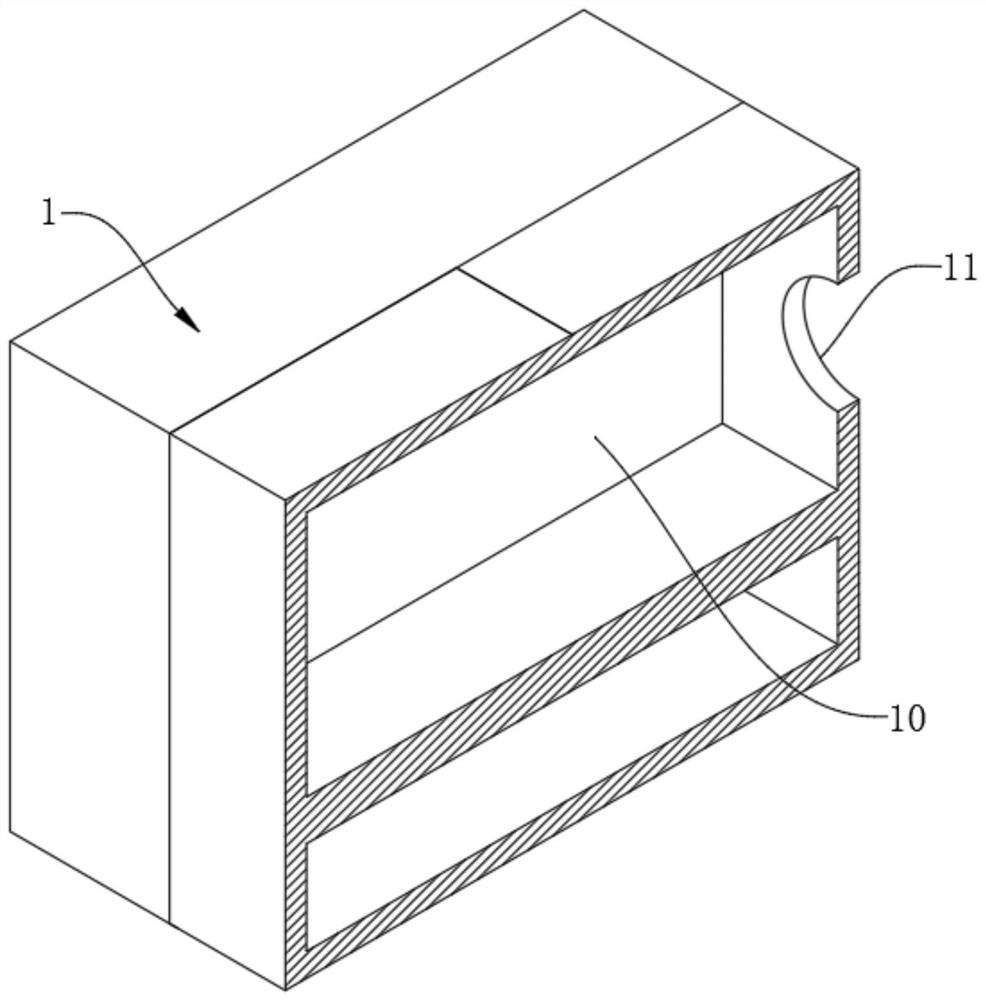

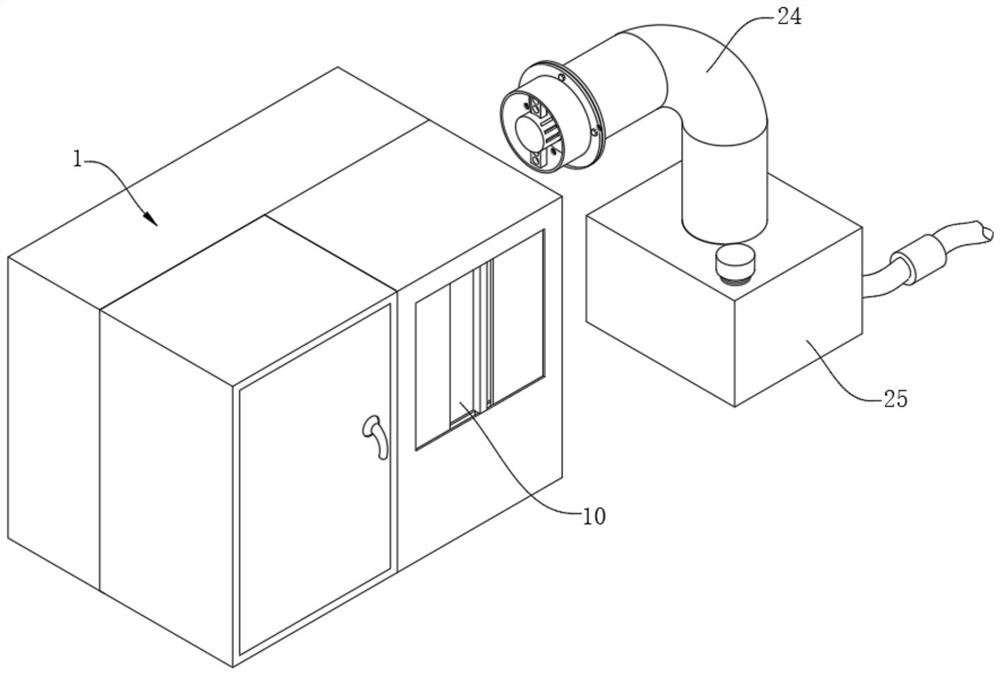

[0029] A semiconductor electroplating machine, such as Figure 1 to Figure 5 As shown, including the device main body 1, the interior of the device main body 1 is provided with a cavity 10, and a through hole 11 communicating with the outside is provided on one side wall of the cavity 10; the device main body 1 is also provided with a waste gas treatment device 2 The exhaust gas treatment device 2 includes a sleeve 20 tightly welded on the wall of the through hole 11. The sleeve 20 is a hollow columnar structure. The cover 27 is internally provided with an annular groove communicating with the outside world, and one end is a closed cylindrical structure. The driving motor 21 is located in the annular groove inside the protective cover 27, and the size of the driving motor 21 is the same as that of the annular groove inside the protective cover 27. The dimensions are matched to ensure that the driving motor 21 can be stably placed in the annular groove inside the protective cov...

Embodiment 2

[0041] In the specific operation, in order to ensure that the exhaust gas enters the exhaust pipe 24 more smoothly, the device main body 1 is improved on the basis of Embodiment 1. As a preferred embodiment, such as Figure 6 As shown, one side of the main body 1 of the device is tightly welded with a fixed plate 3 arranged horizontally, the fixed plate 3 is provided with a fan 30, the fan 30 is provided with a fixed base, and the fixed base is provided with several The threaded hole through the threaded hole, the threaded hole in the fixed base facing the fan 30 in the fixed plate 3 is also provided with a threaded hole connected with the outside world, and then the fixed base on the fan 30 is fixed and installed on the fixed base with fastening bolts. It can be installed on board 3, which is convenient for installation;

[0042] The air outlet pipe on the fan 30 is connected with the cavity 10, and the cavity wall of the cavity 10 is provided with a through hole for the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com