Folding fabricated building prefabricated superposed shear wall, beam and plate mounting rectangular steel frame supporting system

A technology of superimposed shear walls and support systems, applied in the direction of construction, building structure, house structure support, etc., can solve the problems that walls, beams, and slabs cannot be installed at the same time, scaffolding instability, safety accidents, etc. Stability, good overall stability, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

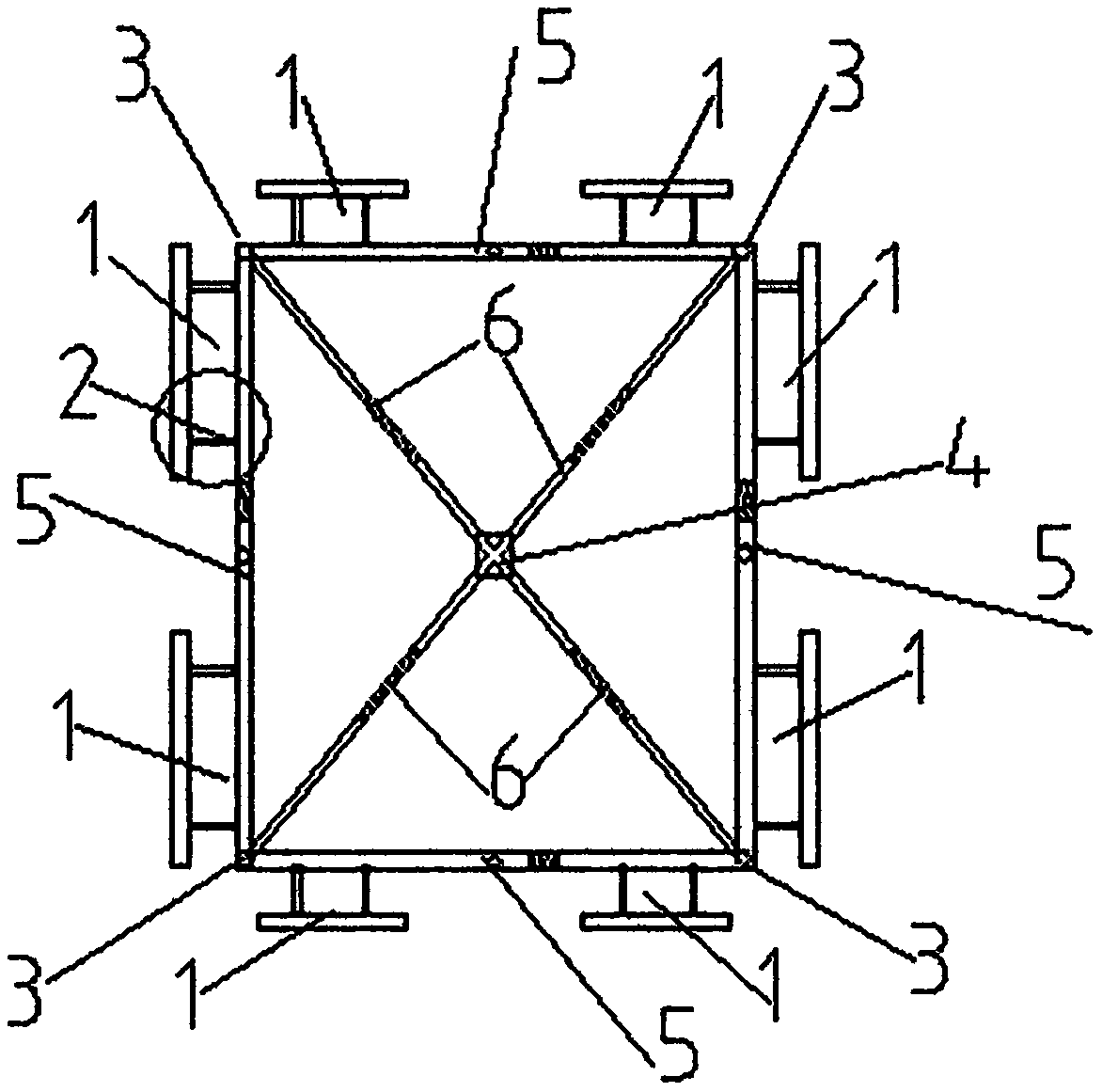

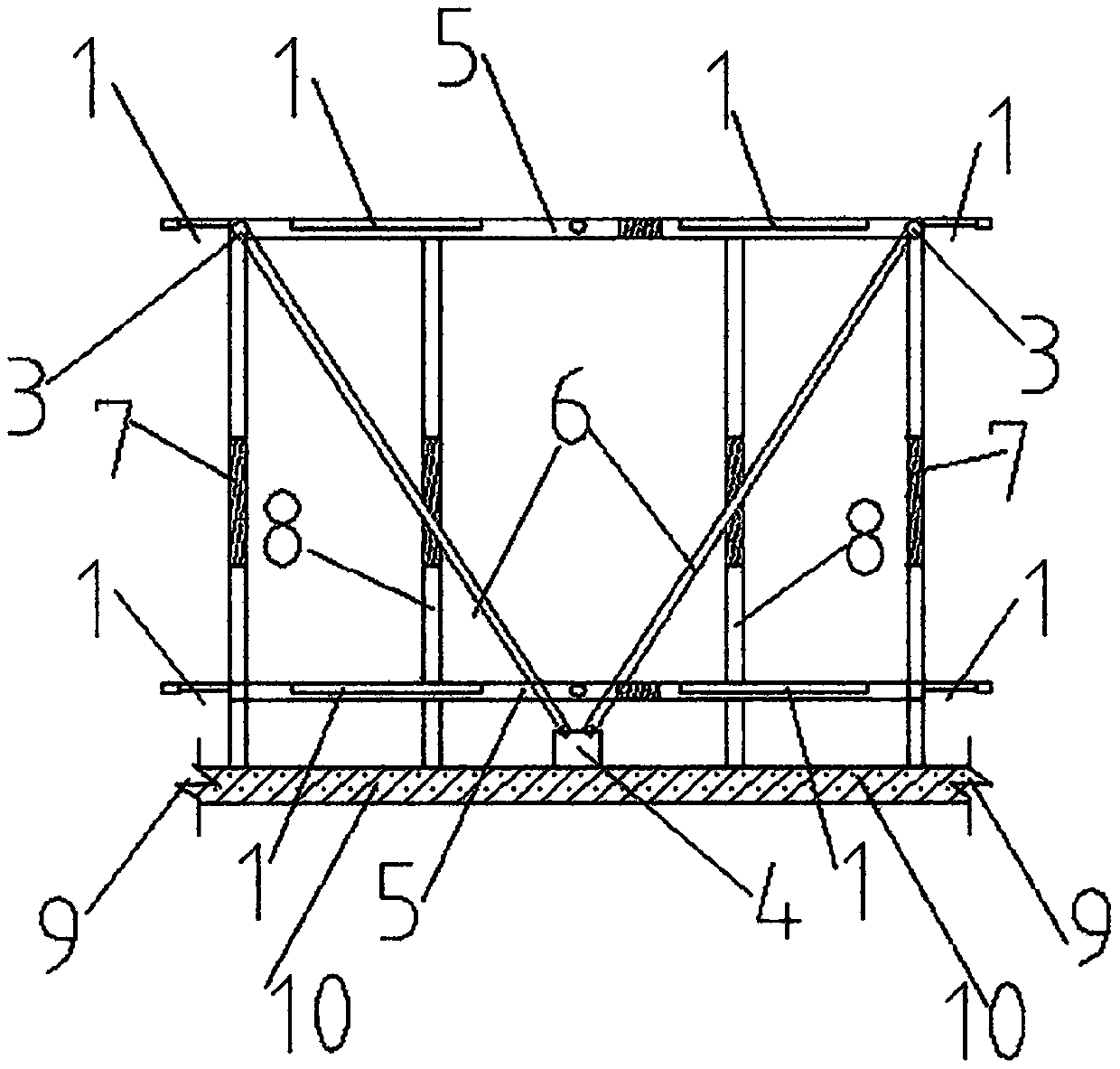

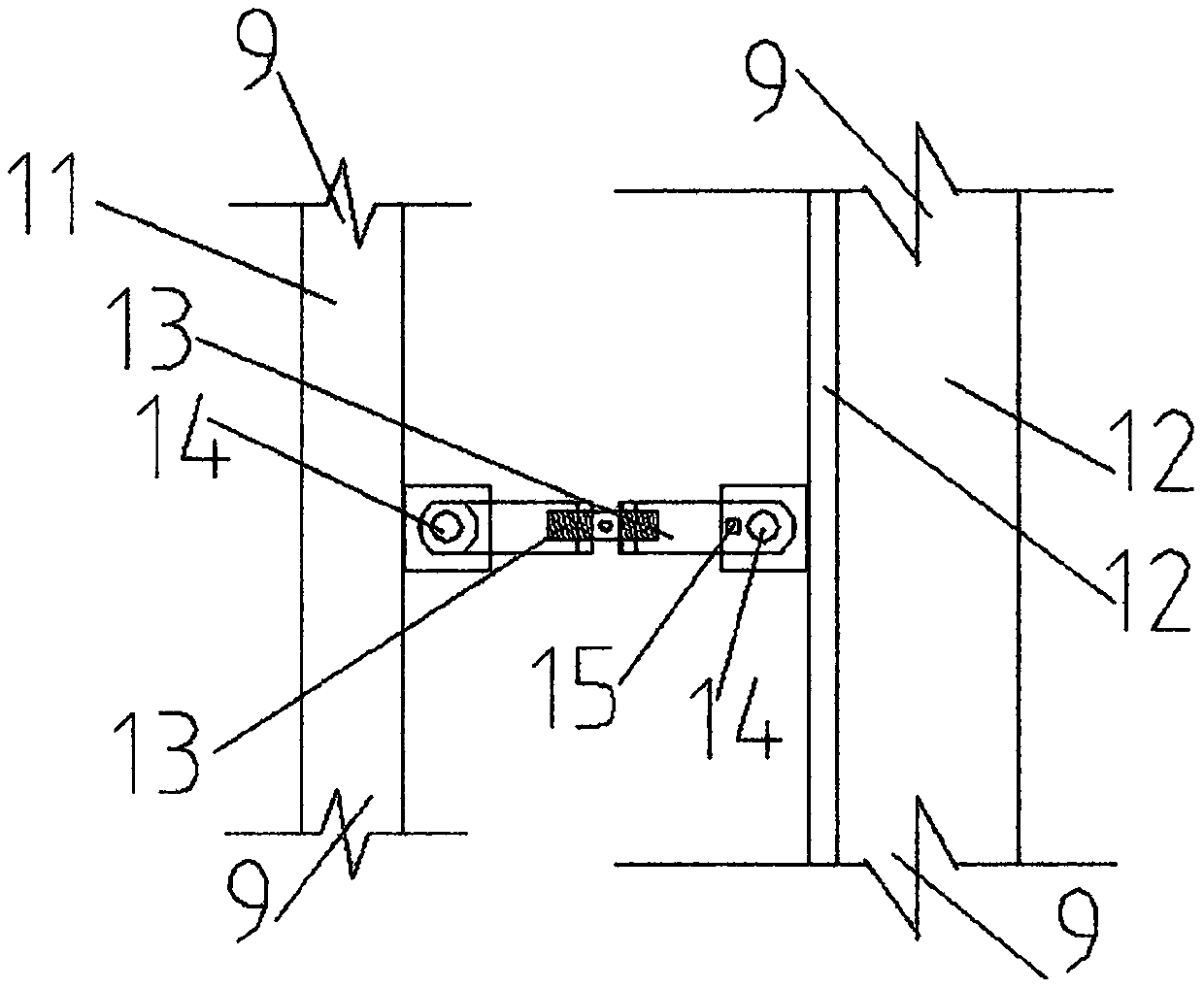

[0055] When assembling the folded rectangular steel frame supports of rooms of different sizes on the construction site, the right-angle connectors of the folded rectangular steel frame are connected to the high side of the rectangular steel frame that can be adjusted in length, and the foldable long and wide sides of the rectangular steel frame that can be adjusted in length are fixed on the The central connector on the bottom surface of the rectangular steel frame on the floor that has been constructed can be adjusted in length. The central oblique support of the rectangular steel frame, the right-angled side and the oblique support form multiple triangles to form a stable rectangular steel frame for the room; the right-angled side of the rectangular steel frame and Planar scissor braces form a simple rectangular steel frame support; the rectangular steel frame with oblique supports in the center of the rectangular steel frame and the simple rectangular steel frame composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com