Construction method for tool-type all-steel construction platform of elevator shaft

A technology for construction platform and elevator shaft, which is applied in the direction of housing structure support, housing structure support, and scaffolding supported by housing structure, etc. problems, to achieve the effect of saving steel pipe rental costs, convenient processing, and simple reinforcement procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

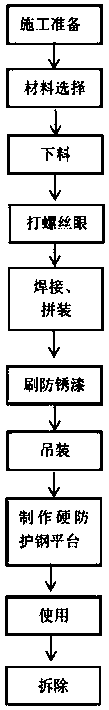

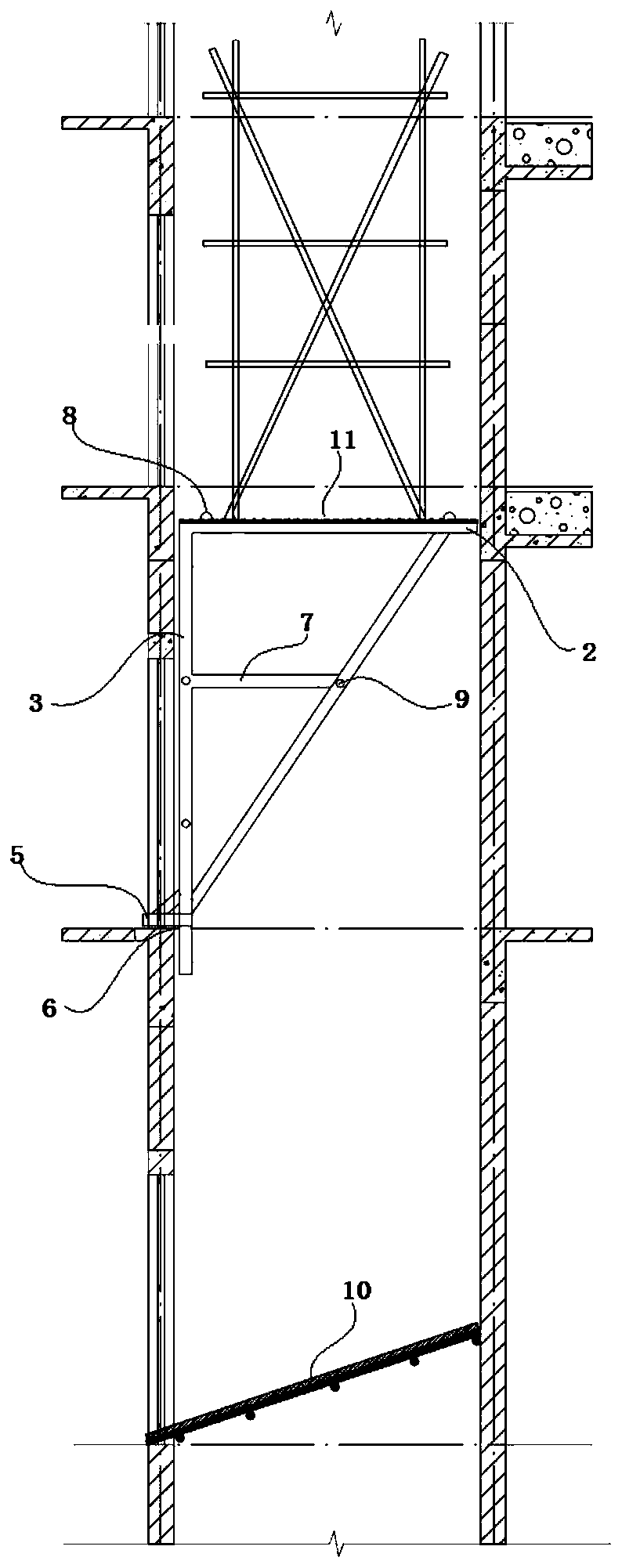

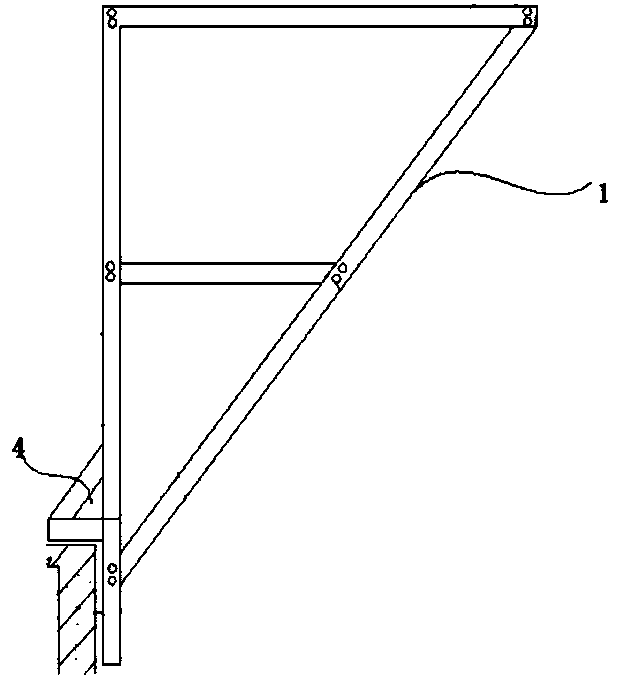

Method used

Image

Examples

Embodiment 1

[0058] The calculation is based on the construction building number of Baoshan Yongchang Jingyuan Construction Project (2 buildings on the 31st floor and 2 buildings on the 32nd floor). On average, 40 meters of steel pipes per layer of each elevator shaft are taken), during the entire main construction process, the maximum amount of steel pipes required for each elevator shaft is 378*40=15120 meters, the daily rent of steel pipes is 1.9 yuan / ton, and the steel pipes per meter If the weight is 3.84Kg, the daily rent of steel pipes = 15120 meters * 3.84Kg / m ÷ 1000 * 1.9 yuan / ton. Day = 110.3 yuan, the rent of fasteners (including cleaning fees) is 0.01 yuan / piece * day, and each layer of fasteners is 15, a total of 378 floors * 15 = 5670; the daily rent of fasteners = 5670 * 0.01 yuan / piece = 56.7 yuan / day; the daily rent of steel pipes and fasteners = 110.3 yuan + 56.7 yuan = 167 yuan. The construction period of the main body is calculated as 330 days. During the construc...

Embodiment 2

[0064] Baoshan Qingyang Phase II Project is a shanty town reconstruction project, a public opinion project launched by the Chinese government to transform dilapidated and old housing in cities and improve the housing conditions of families in need. Household types 5, 6, 7, and 8 of A type: 11 floors above ground, The height of the building is 35.55m, the first floor is commercial, the storey height is 4.4m, the residential floor is 3.0m high, and the first floor is underground. 11 Buildings of Type B: 16 floors above ground, building height 49.95m, residential floor height 3.0m, and one basement. Buildings 9, 10, 17, 18, and 21 of C type: 17 floors above ground, building height of 52.92m, residential floor height of 3.0m, of which 9, 10, and 21 buildings have a basement floor, D type 19, 20: 26 floors above ground , the building height is 79.95m, the residential floor height is 3.0m, and the basement is one floor, of which 19 are commercial buildings with a floor height of 4.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com