Indoor heater glass panel heat shock resistance testing device

A technology of glass panels and internal heaters, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the water temperature cannot be accurately guaranteed, and the 10mL/s water flow rate cannot be accurately guaranteed, so as to reduce the test work intensity and reduce randomness , The effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

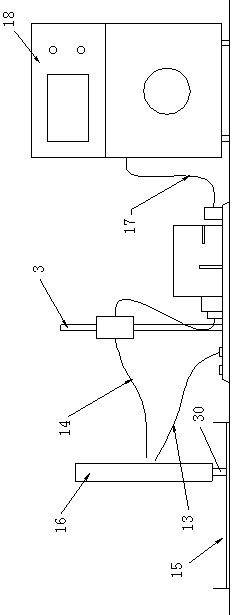

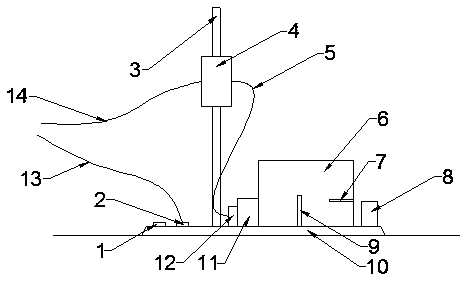

[0041] Accompanying drawing is a kind of specific embodiment of the present invention.

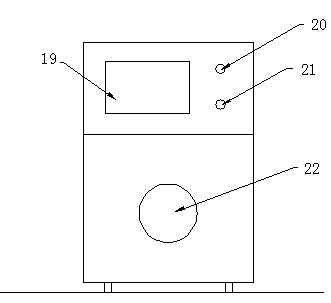

[0042] The indoor heater glass panel thermal shock resistance test device of the present invention includes a water supply device, a power supply device, a prototype temperature measuring device, and a control cabinet 18 respectively connected to them;

[0043] The temperature measuring device of the prototype adopts a temperature sensor 13, and the temperature sensor is connected to the control cabinet;

[0044] The power supply device includes a prototype power supply socket 1 and a thermocouple socket 2, which are installed on the base 10 and connected to the control cabinet;

[0045] The water supply device includes a water tank 6, a water pump 11, a water flow sensor 12 and a water pipe connected to each other. A thermostat (water tank water temperature controller 9) and a temperature sensor 7 are installed in the water tank. The water tank is also installed on the base. The water pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com