Cooling water circulating system of formation table

A circulating system, cooling water technology, applied in sustainable manufacturing/processing, lead-acid battery electrodes, climate sustainability, etc., can solve the problems of unsatisfactory battery cooling effect, consumption of manpower, material resources, low work efficiency, etc. The effect of improving the efficiency of chemical formation, saving resources and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

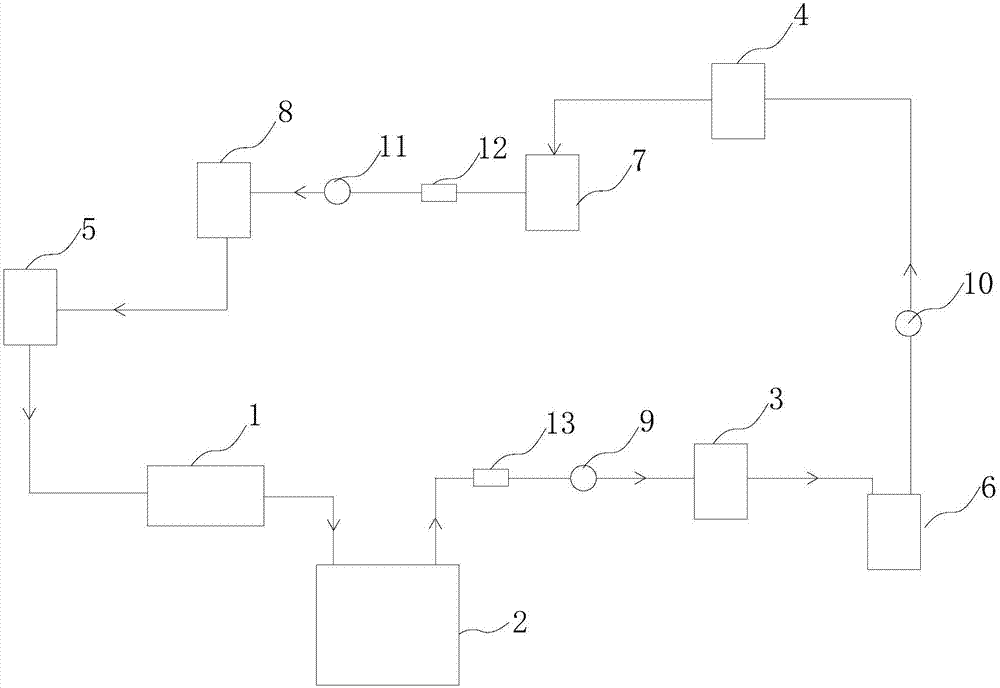

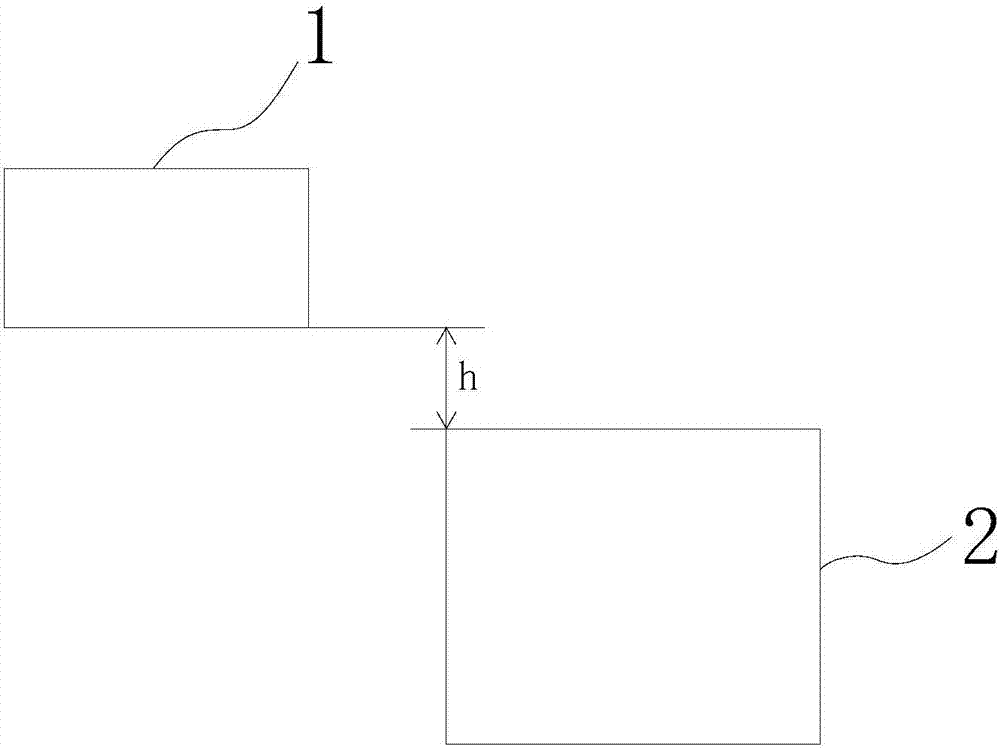

[0035] Such as figure 1 As shown, the present invention provides a cooling water circulation system for a chemical conversion platform, including a chemical conversion platform 1 and a cooling water circulation system, the cooling water circulation system communicates with the chemical conversion platform 1 through a pipeline, and the aqueous solution in the chemical conversion platform 1 Perform a cooling cycle.

[0036] continue as figure 1 As shown, the cooling water circulation system includes a water return device 2, a neutralization device 3, a buffer device 6, a cooling tower 4, a cold water storage device 7, a filter device 8, and a heat exchanger 5, which are arranged in sequence. Made of acid and alkali resistant and anti-corrosion materials.

[0037] The chemical conversion station 1 is used to perform chemical conversion treatment on the battery, and the aqueous solution in the chemical conversion process flows to the water return device 2 by itself through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com