Heating processing technology for deep sea petroleum drill by adopting conduit joint

A technology for conduit joints and oil drills, used in heat treatment furnaces, heat treatment equipment, drill pipes, etc., can solve problems such as residual internal stress, difficult to harden, and thick wall thickness, and achieve stable quenching quality, sufficient heat treatment, and consistent temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The diameter of the conduit joint in this embodiment is 450mm, the maximum wall thickness is 36mm, and the material is 25MnV. The deep-sea oil drill of the present invention adopts the heat treatment process of the conduit joint, which includes the following steps: a. Furnace loading: sequentially load the conduit joint blanks In the well-type quenching furnace, the welding neck end is facing downward, and the periphery of the vertical conduit joint and the interval between the upper and lower layers are 25 mm. b. Quenching: b1. Raise the furnace temperature to 885°C within 60±5 minutes, and then keep it warm for 80 minutes. b2. Stir the water in the quenching pool 5 minutes before the blank of the conduit joint is released from the furnace, and control the water temperature at 30°C to 33°C. b3. It takes 8 seconds for the pipe joint blank to be lifted out of the furnace to enter the quenching pool, and the water cooling time is 15 to 16 minutes. The water temperature do...

Embodiment 2

[0015] The diameter of the conduit joint in this embodiment is 940mm, the maximum wall thickness is 78mm, and the material is 25MnV. The deep-sea oil drill of the present invention is produced by adopting the heat treatment process of the conduit joint. It includes the following steps: a. Put it into the well-type quenching furnace, with the welding neck facing down, and the interval between the vertical conduit joint and the upper and lower layers is 50 mm. b. Quenching: b1. Raise the furnace temperature to 895°C within 60±5 minutes, and then keep it warm for 125 minutes. b2. Stir the water in the quenching pool 5 to 7 minutes before the conduit joint blank is released from the furnace, and control the water temperature at 32°C to 36°C. b3. It takes 10-15 seconds for the pipe joint blank to be lifted out of the furnace to enter the quenching pool, and the water cooling time is 17-20 minutes. The water temperature does not exceed 48°C at the end of quenching. c. Normalizing: ...

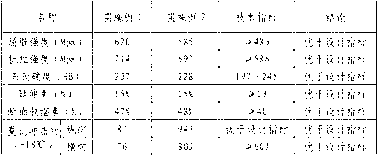

Embodiment 1 and Embodiment 2

[0016] Example 1 and Example 2 main mechanical properties sampling test table

[0017]

[0018] The above-mentioned embodiment is a preferred example of the present invention. Even if some adjustments are made within the scope of the process index, a similar heat treatment effect can be obtained. The mechanical properties of the heat-treated conduit joint can meet the design requirements, and the first pass rate is above 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com