Testing device for friction power generator

A friction generator and testing device technology, which is applied in the direction of motor generator testing, measuring devices, measuring device casings, etc., can solve the problems of poor accuracy of testing devices, achieve easy mobile use, small footprint, and improve testing accuracy degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

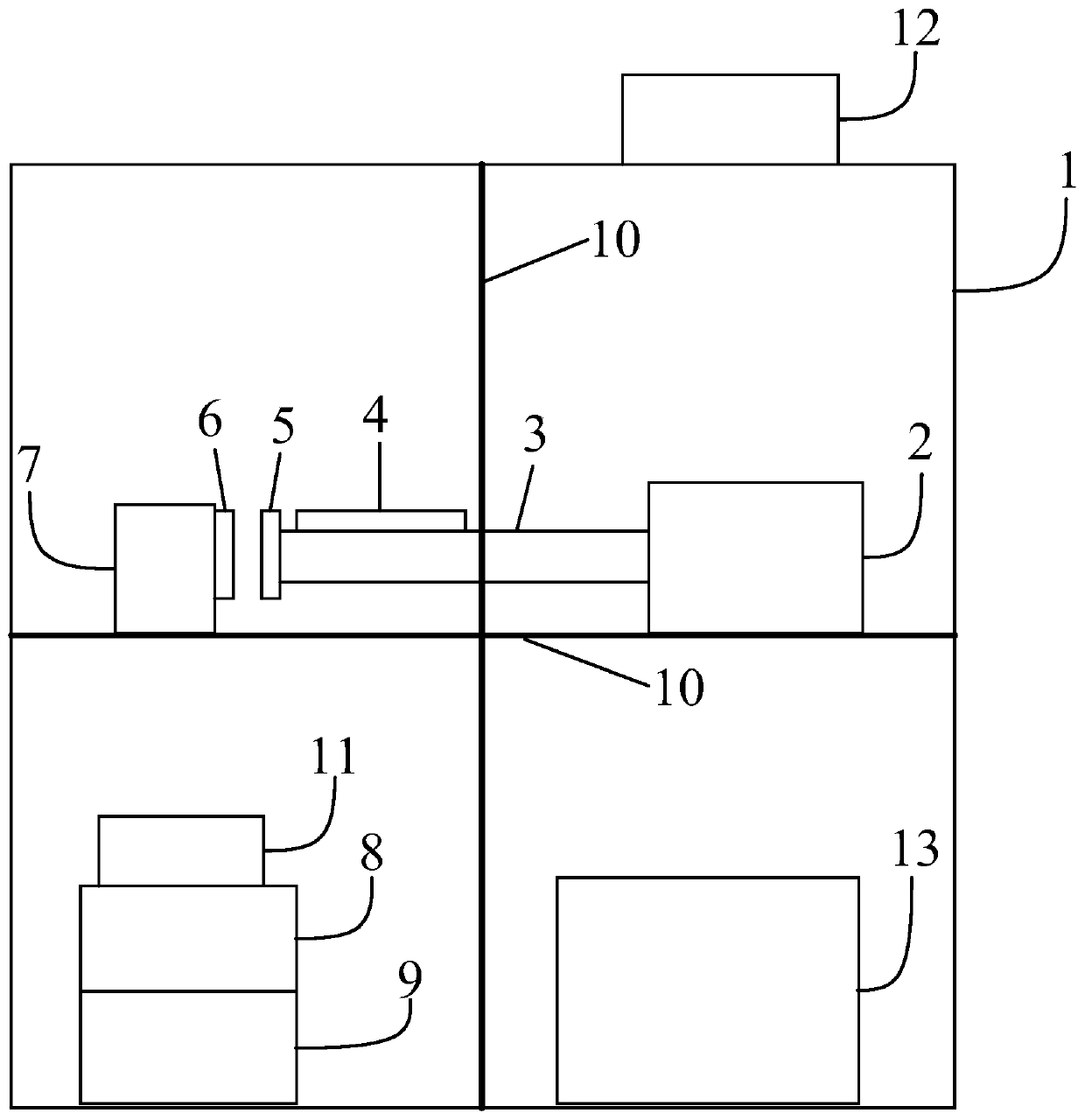

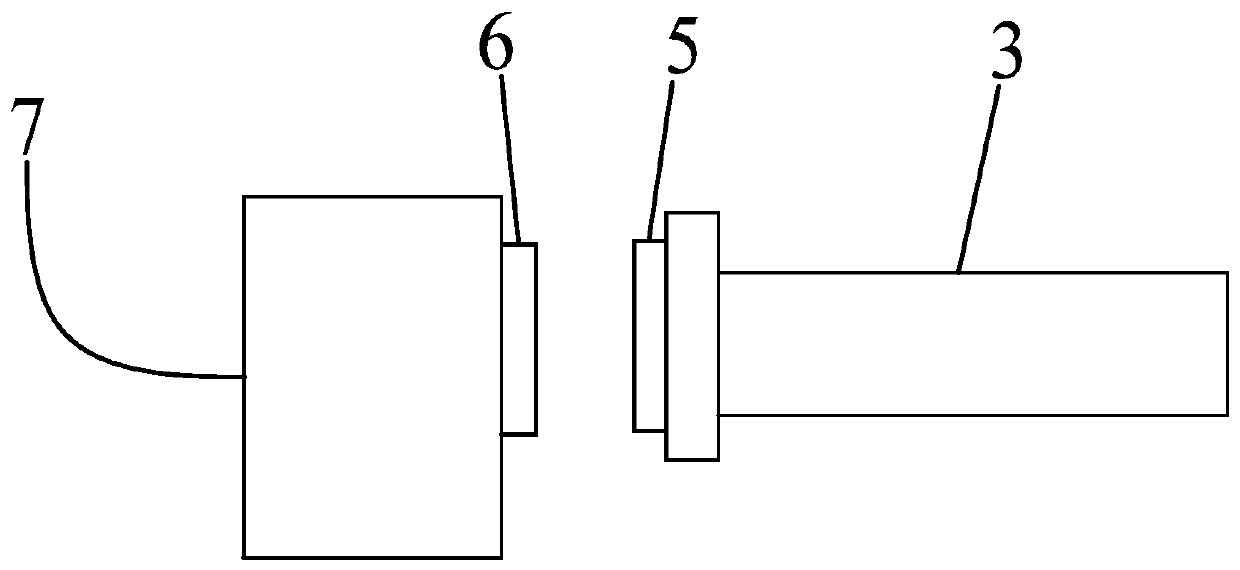

[0050] The present embodiment 1 provides a friction generator testing device, figure 1 It is a structural diagram of the friction generator testing device provided by Embodiment 1 of the present invention. see figure 1 , the friction generator testing device includes: a shielding box 1, a linear motor 2, a motor push rod 3, a solid-liquid vibration fixed table 4, a magnetic sample plate, a friction generator to be tested, a flat pressure sensor 7, an ammeter 8 and Voltmeter9. The friction generator to be tested in this embodiment 1 is a solid-liquid friction generator or a solid-solid friction generator.

[0051] The interior of the shielding box is divided into four spaces with a partition 10, specifically the inside of the shielding box is divided into a first space and a second space with a first partition, and the first space is divided into a third space and a second space with a second partition. Four spaces, the second space is divided into the fifth space and the si...

Embodiment 2

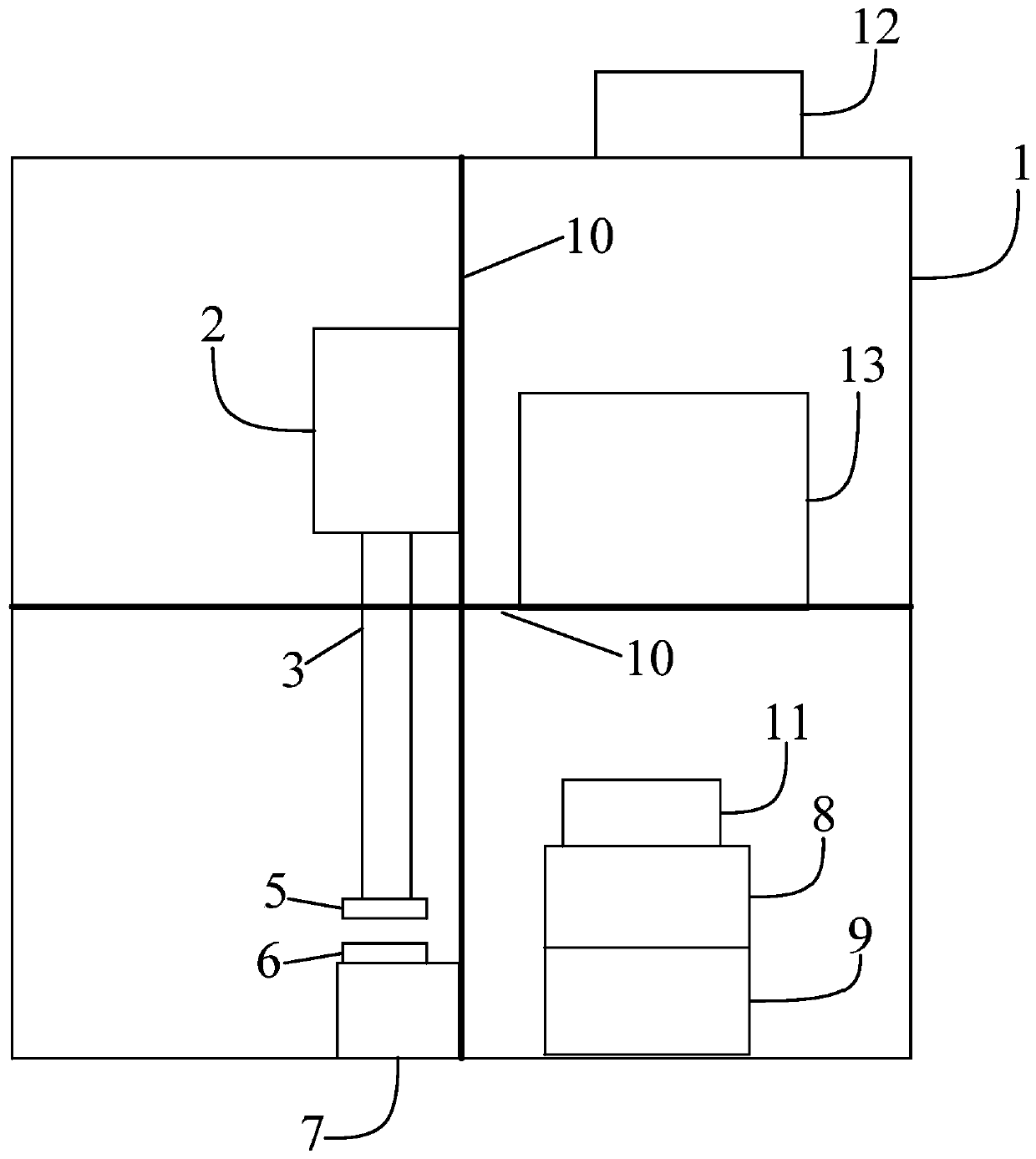

[0084] This embodiment 2 provides a friction generator testing device, image 3 It is a structural diagram of the friction generator testing device provided by Embodiment 2 of the present invention. see image 3 , the friction generator testing device includes: a shielding box 1, a linear motor 2, a motor push rod 3, a magnetic sample plate, a friction generator to be tested, a flat pressure sensor 7, an ammeter 8 and a voltmeter 9. The friction generator to be tested in Example 2 is a solid-solid friction generator.

[0085] The inside of the shielding box is divided into the first space and the second space by the first partition, the first space is divided into the third space and the fourth space by the second partition, and the second space is divided into the fifth space by the third partition and the sixth space. The shielding box is a Faraday shielding box. The material of the shielding box of present embodiment 2 can be good conductors such as copper, aluminum and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com