A preventive maintenance method and workshop manufacturing system based on failure impact analysis

A technology of impact analysis and manufacturing system, applied in the direction of manufacturing computing system, data processing application, instrument, etc., can solve the failure rate and mean time between failures are not applicable, the reliability evaluation of the manufacturing system in the workshop is less, and the maintenance of the manufacturing system in the workshop Problems such as unsatisfactory control and management effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

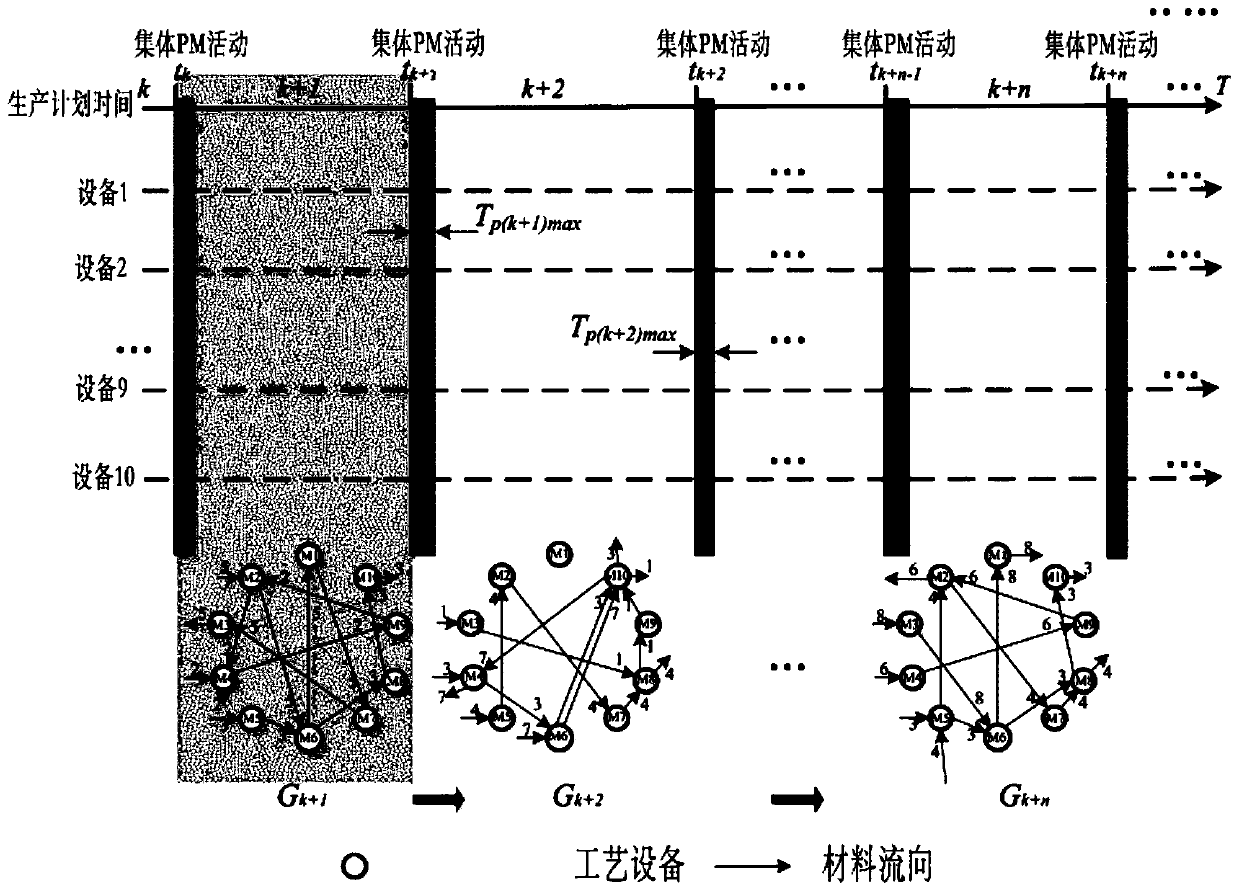

[0098] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

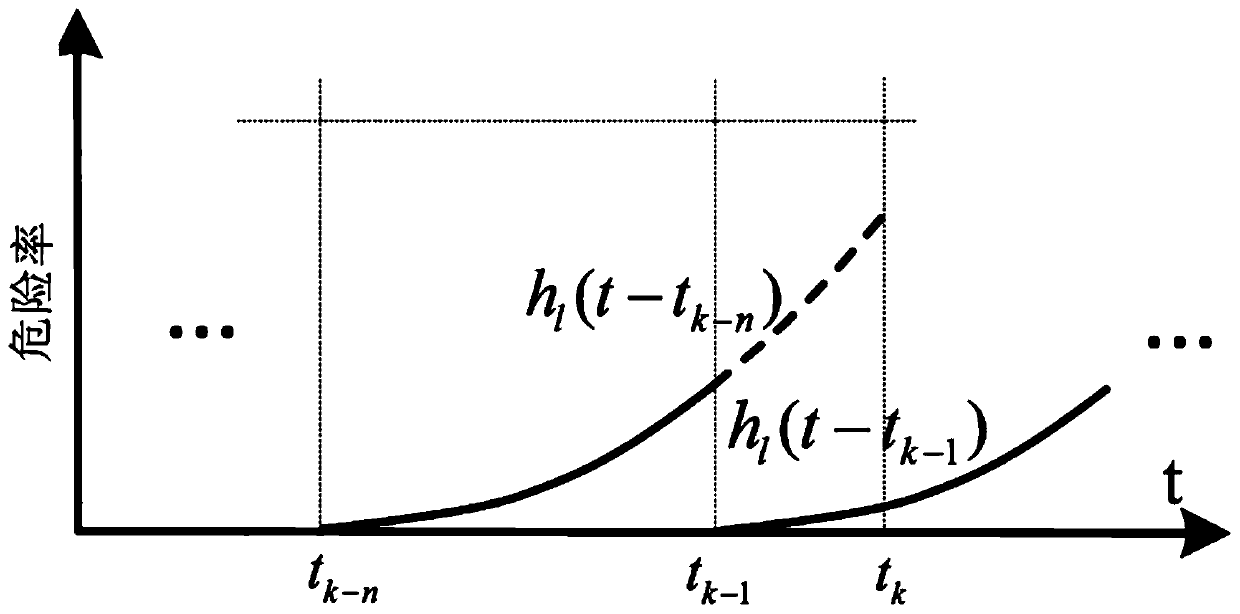

[0099] A preventive maintenance method based on fault impact analysis, which is applied to the workshop manufacturing system, and the workshop manufacturing system includes, in addition to equipment and components, also includes: modeling module, evaluation setting module, failure analysis module, maintenance strategy Planning module, reliability evaluation module and importance measurement and reliability improvement module;

[0100] The preventive maintenance method includes the steps of:

[0101] 1. Use the modeling module to establish a network model, and complete the model assumptions and variable descriptions:

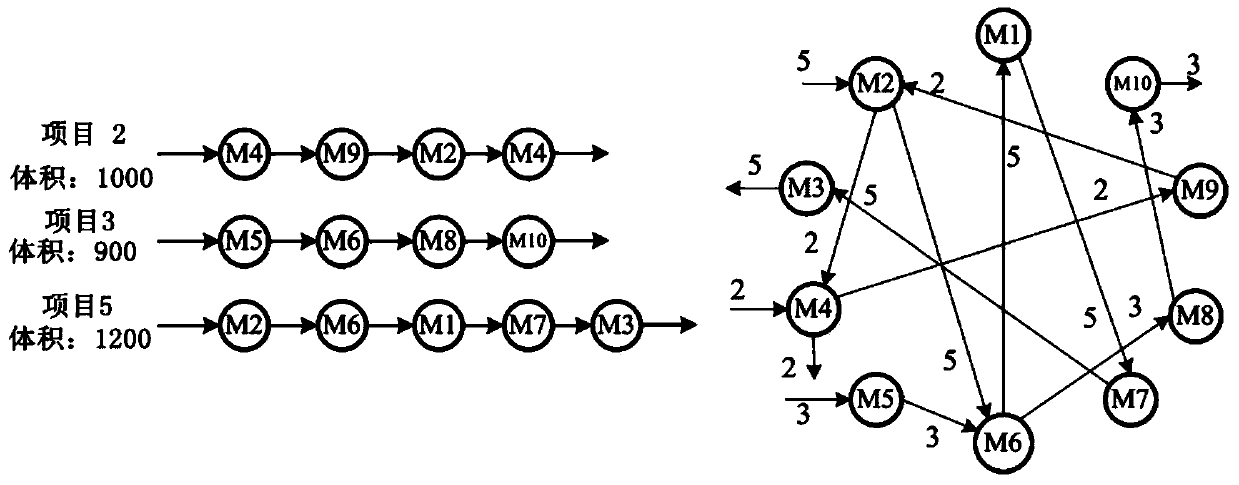

[0102] The structure of a job shop manufacturing system is often in constant change with the flow of material on the shop floor. Parts pass through special or flexible machines accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com