Dumping furnace smelting brown aluminum oxide self-baking electrode and production technology thereof

A self-baking electrode and production process technology, applied in the direction of electric heating devices, electrical components, heating through discharge, etc., can solve the problems of falling blocks, hanging paste in the roasting process, unqualified self-baking electrode quality, etc., to achieve good quality and narrow the scope Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is a further detailed description through specific implementations:

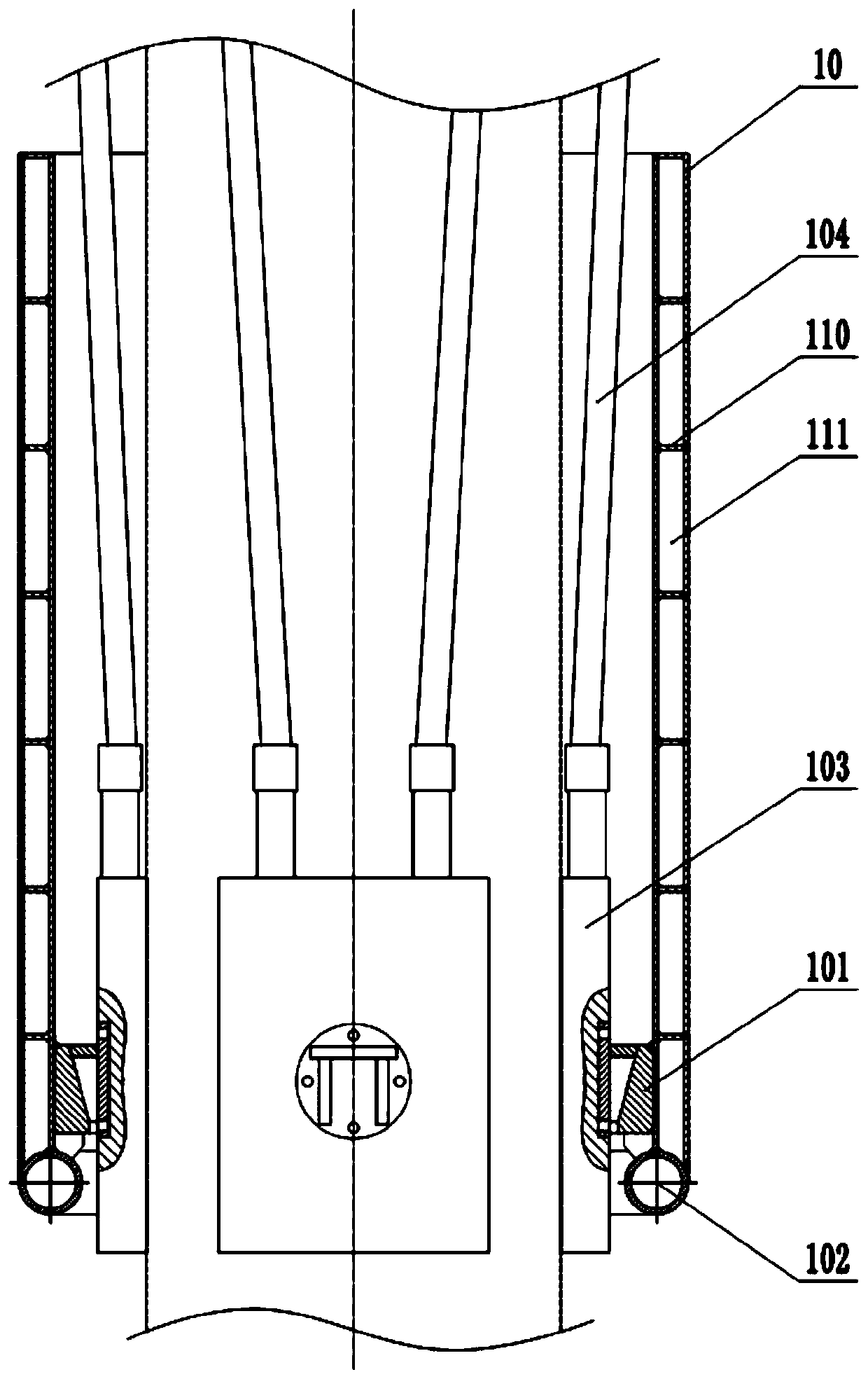

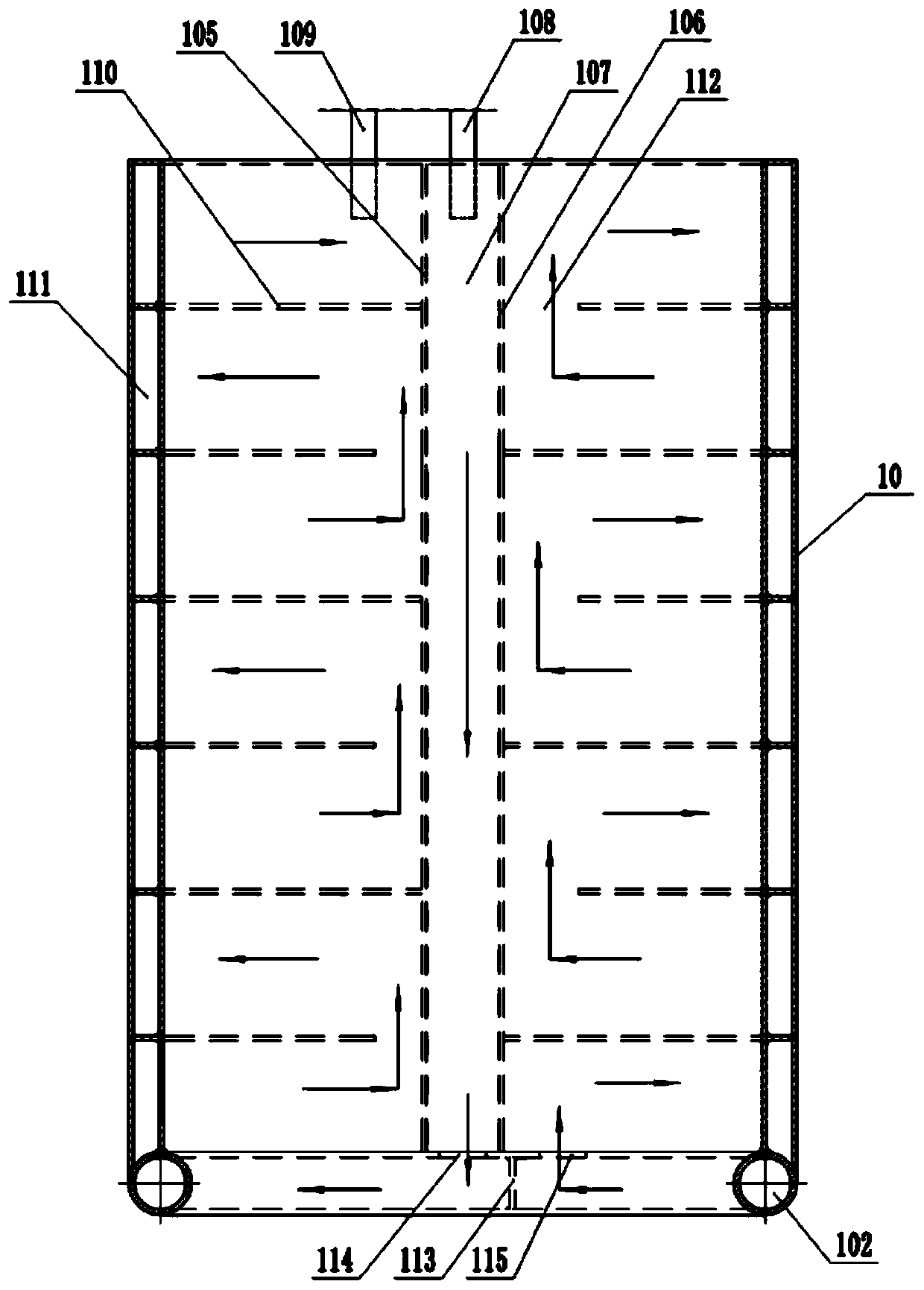

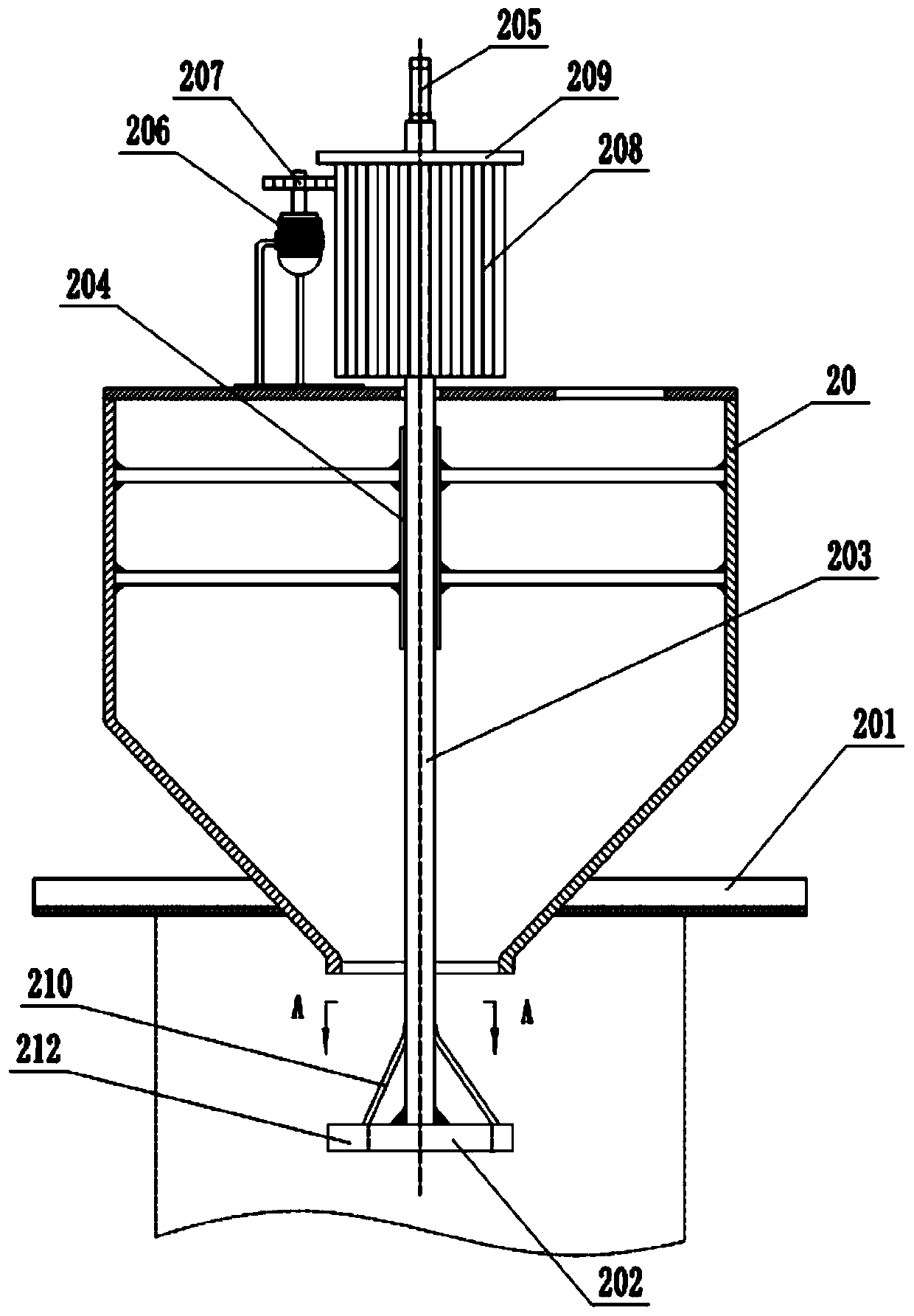

[0032] The reference signs in the drawings of the specification include: sheath 10, conical ring 101, annular tube 102, copper tile 103, copper tube 104, protective plate Ⅰ 105, protective plate Ⅱ 106, water inlet cavity 107, water inlet pipe 108, and Water pipe 109, water baffle 110, circulation cavity 111, gap 112, water baffle 113, water inlet 114, water outlet 115, bucket 20, support plate 201, baffle 202, rotating shaft 203, support tube 204, lifting lug 205 , Motor 206, driving gear 207, driven gear 208, limit disc 209, sector plate 210, shielding plate 211, sector hole 212.

[0033] A self-baking electrode for smelting brown corundum in a dumping furnace, which is made by baking the electrode paste. The self-baking electrode has a diameter of 690~710mm and a bulk density of 1.3~1.5g / cm 3 , The volatile content of the electrode paste is 10.0-11.8% by weight.

[0034] The inventors have o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com