Electric coagulation and electric cutting pliers

A technology of electrocution and electrocoagulation, which is applied in the field of medical devices, can solve the problems of poor surgical operation accuracy and precise electrocution of difficult target tissues, and achieve good applicability, reduce the number of parts, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

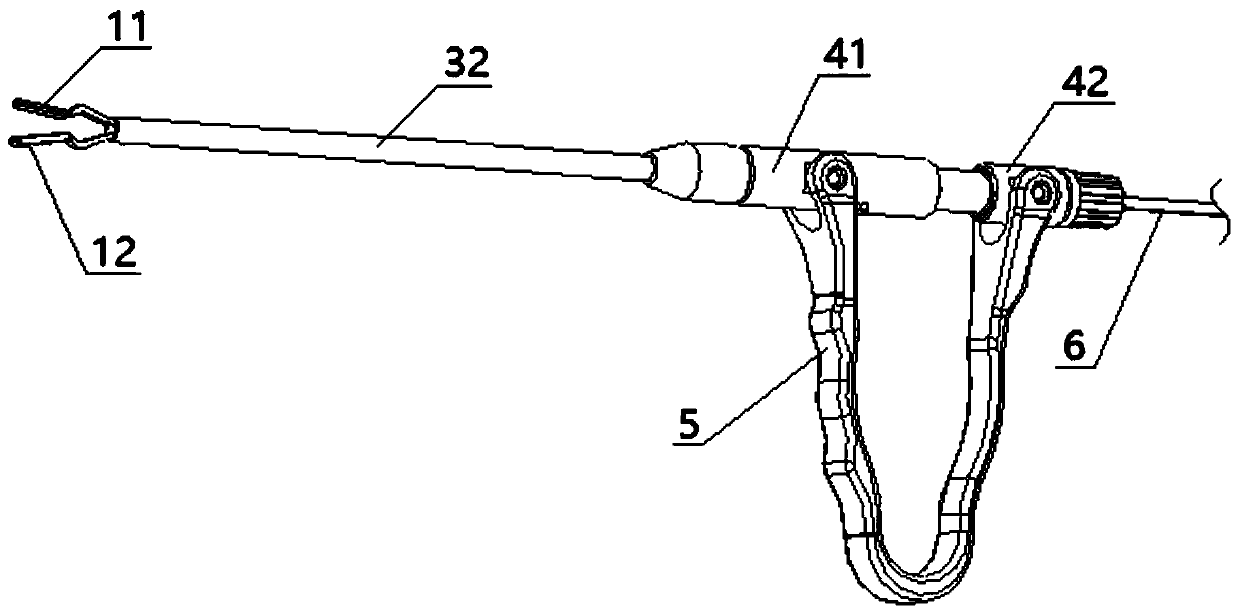

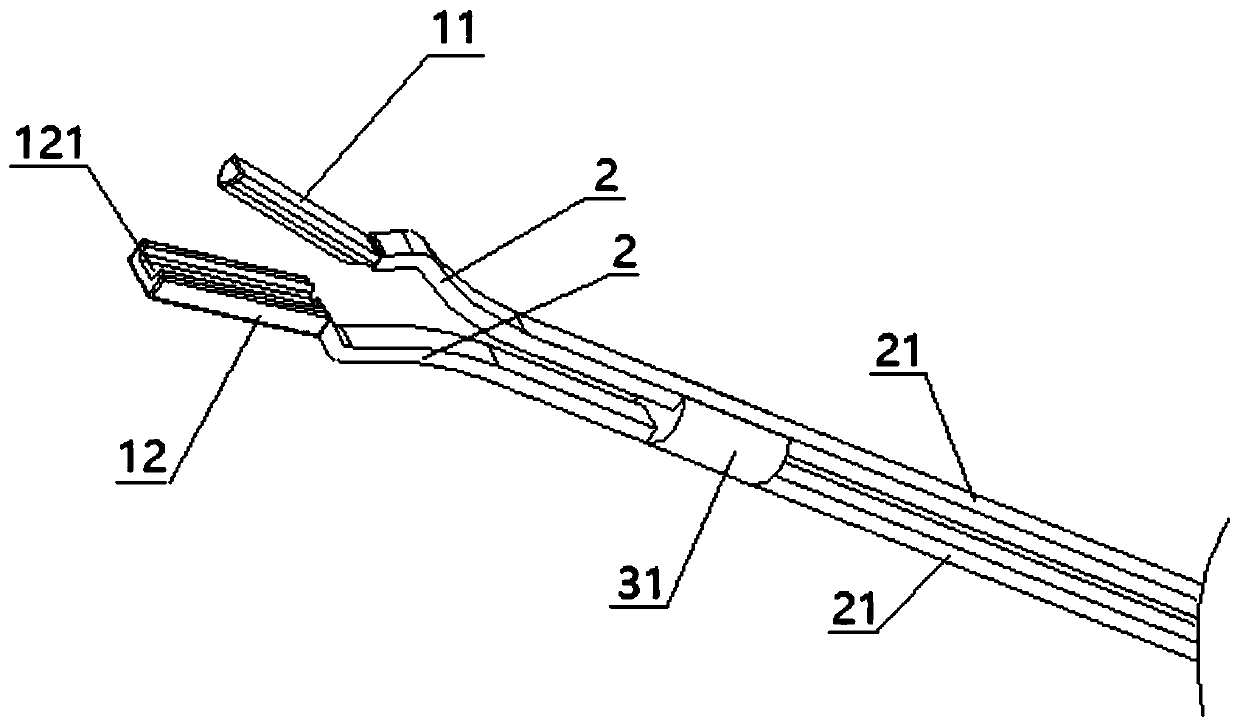

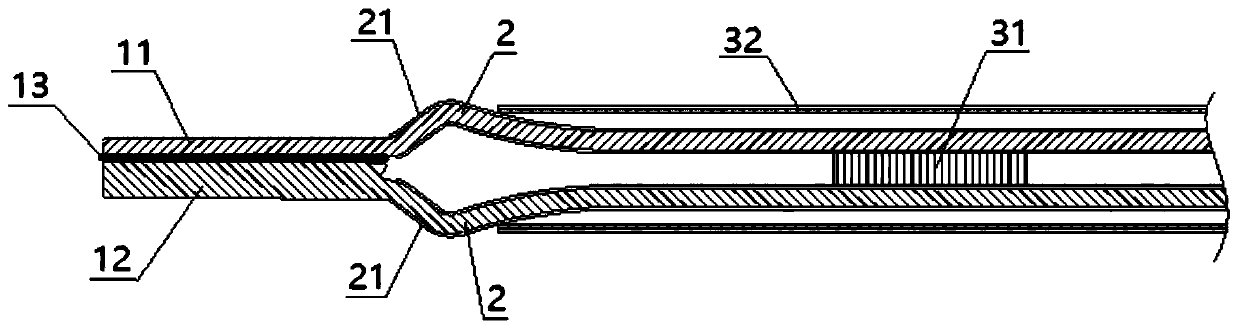

[0044] Please refer to Figure 1-4 , This embodiment provides an electrocoagulation cutting pliers, including a first electrode 11 and a second electrode 12 arranged in pairs, at least one of the first electrode 11 and the second electrode 12 is at a separate position and relative to the other. Move between the approaching positions; when the first electrode 11 and the second electrode 12 are in the approaching position, the distal ends of the first electrode 11 and the second electrode 12 are aligned planes perpendicular to the extending direction of the distal ends. A first electrical insulation layer 13 is provided between the first electrode 11 and the second electrode 12, and the first electrical insulation layer 13 is an elastic electrical insulation layer. The opposite sides of the first electrode 11 and the second electrode 12 are respective clamping parts, and the contact area between the clamping part of the first electrode 11 and the tissue is smaller than the contact...

Embodiment 2

[0052] The difference between this embodiment and the first embodiment is that a gap is left between the first electrode 11 and the second electrode 12. By leaving a gap between the first electrode 11 and the second electrode 12, the two electrodes cannot be contacted and conducted. The size of the gap can be adjusted according to the voltage, thereby optimizing the structure of the operating terminal electrode, and improving the accuracy and effect of point touch hemostasis.

Embodiment 3

[0054] In the present application, the distal ends of the first electrode 11 and the second electrode 12 are flush, which means that the connection between the ends of the first electrode 11 and the second electrode 12 is closest to the first electrode 11 and the second electrode. The extension direction of 12 is vertical.

[0055] Please refer to Figure 5 In this embodiment, a structure in which the ends of the first electrode 11 and the second electrode 12 are flush is provided. The end of the first electrode 11 is a bevel, the end of the second electrode 12 is a plane, and the first electrode 11 and the second electrode 12 are flat. The connection line at the closest position of the electrode 12 is still perpendicular to the extending direction of the electrode, that is, the first electrode 11 and the second electrode 12 are flush.

[0056] Please refer to Image 6 with Figure 7 In other embodiments, the first electrode 11 and the second electrode 12 can also be arranged as s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com