Dendrobium officinale cooking machine

A technology of Dendrobium candidum and cooking machine, which is applied in the directions of plant raw materials, household components, applications, etc., can solve the problem of not being able to automatically process fresh Dendrobium candidum strips, and can not automatically complete the cleaning, cutting, crushing, and steaming of fresh Dendrobium candidium strips And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

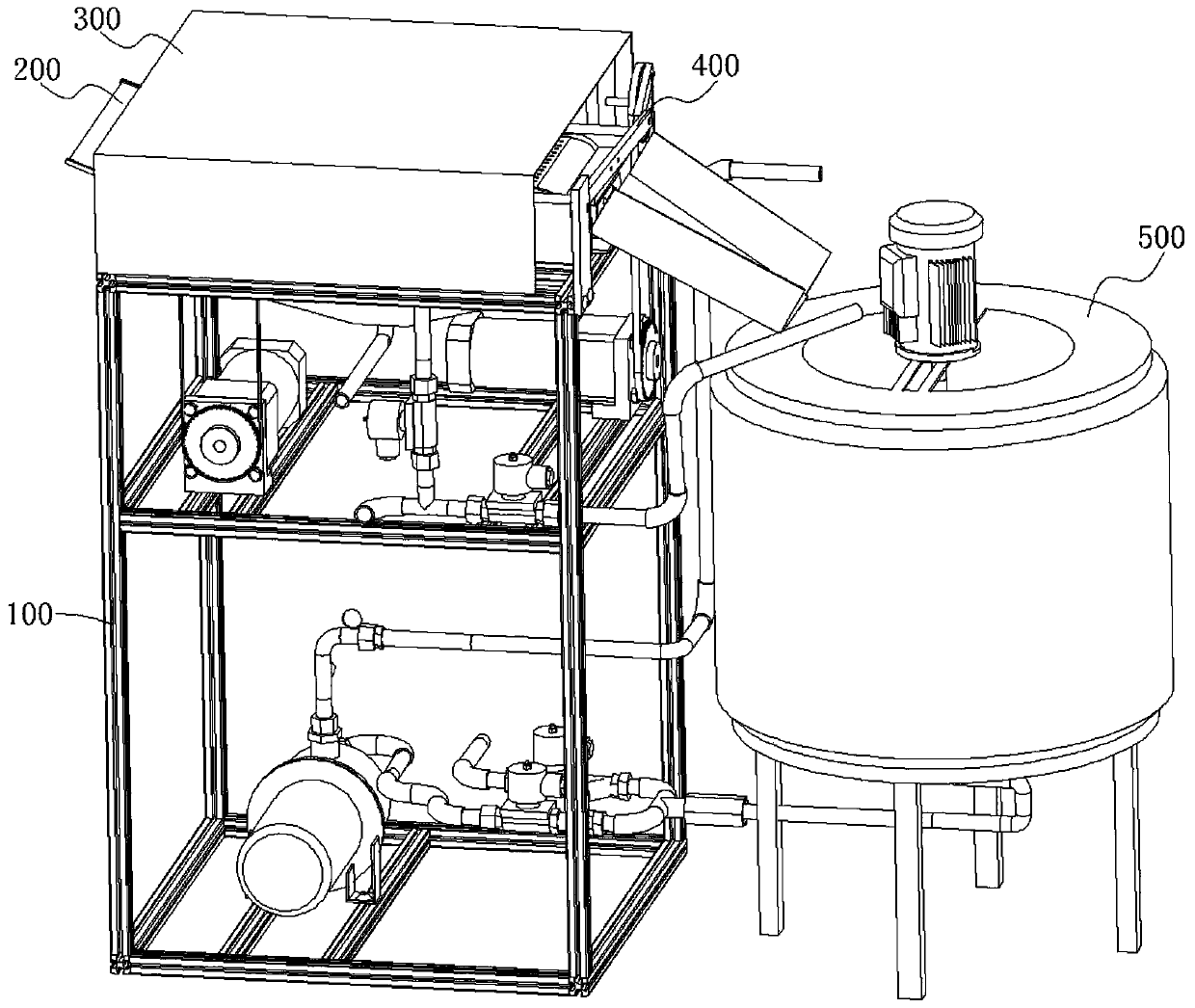

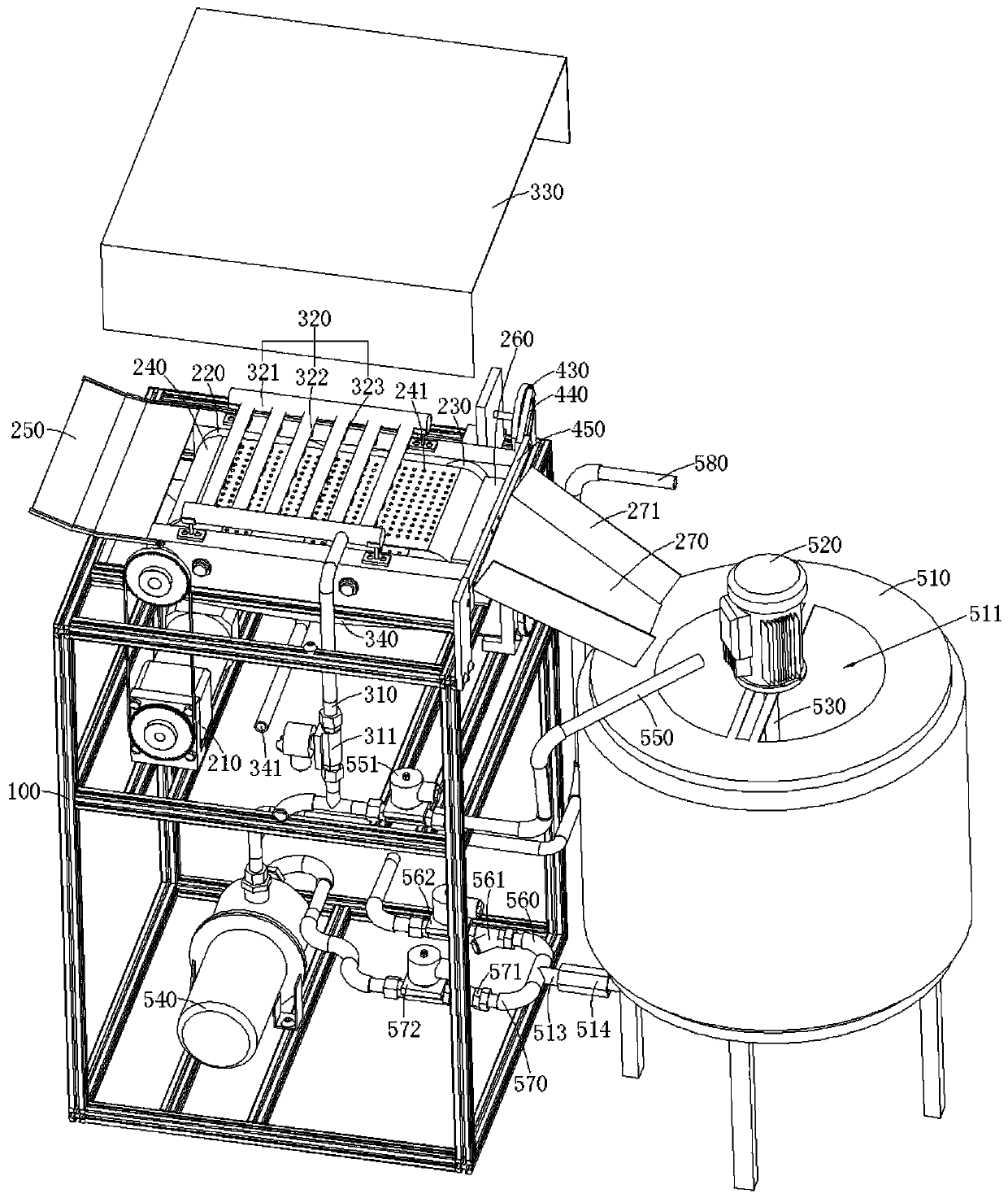

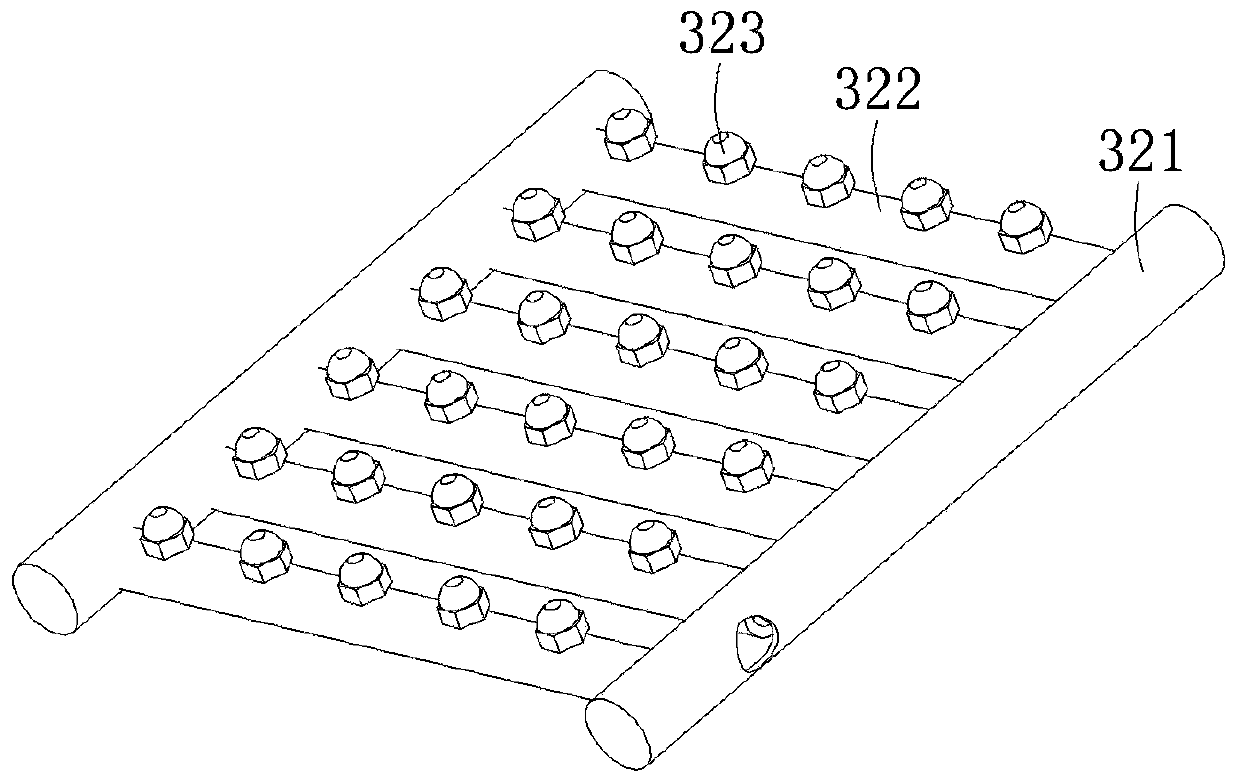

[0025] A kind of dendrobium candidum cooking machine, see figure 1 and figure 2 , including a frame 100, a conveying device 200, a cleaning device 300, a cutting device 400, a cooking device 500, and an industrial computer (not shown). Wherein, the conveying device 200 is arranged on the frame 100, which is used to transport Dendrobium candidum; the cleaning device 300 is arranged directly above the conveying device 200, and is used for cleaning the Dendrobium candidum during transportation; the cutting device 400 is arranged on the conveying The end of the feeding direction of device 200, it is used to cut the Dendrobium candidum after cleaning; The cooking device 500 is arranged on the end of the feeding direction of the conveying device 200, and it is used for cooking the Dendrobium candidum after cutting; The industrial computer is respectively connected with the conveying device 200, The cleaning device 300, the cutting device 400, and the cooking device 500 are electri...

Embodiment 2

[0039] A steaming machine for Dendrobium candidum, which differs from the steaming machine for Dendrobium candidum described in Embodiment 1 in that: the water outlet of the second waterway 550 is located directly above the discharge plate 270, and the water in the second waterway 550 can flow along the discharge plate 270. Plate 270 flows into heating tank 510 . Through this design, the Dendrobium candidum on the discharge plate 270 can be flushed into the heating tank 510 to prevent the Dendrobium candidum from sticking to the discharge plate 270 .

Embodiment 3

[0041] A kind of dendrobium candidum cooking machine, see Figure 6 , the difference between it and the Dendrobium candidum cooking machine described in Embodiment 1 is:

[0042] One end of the third waterway 560 communicates with the water outlet of the drain pipe 513, and the other end of the third waterway 560 communicates with the water inlet of the water pump 540;

[0043] A fifth valve 581 is provided on the fifth waterway 580. In this embodiment, the fifth valve 581 is an electric valve in the prior art;

[0044] The cooking device 500 also includes a sixth waterway 590, the water inlet of the sixth waterway 590 communicates with the water outlet of the water pump 540, and the water outlet of the sixth waterway 590 is used to discharge qualified feed liquid, and the sixth waterway 590 is provided with a sixth valve 591. In this embodiment, the sixth valve 591 is an electric valve in the prior art.

[0045]The draining process of the Dendrobium candidum cooking machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com