Patents

Literature

59results about How to "Fully automatic processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

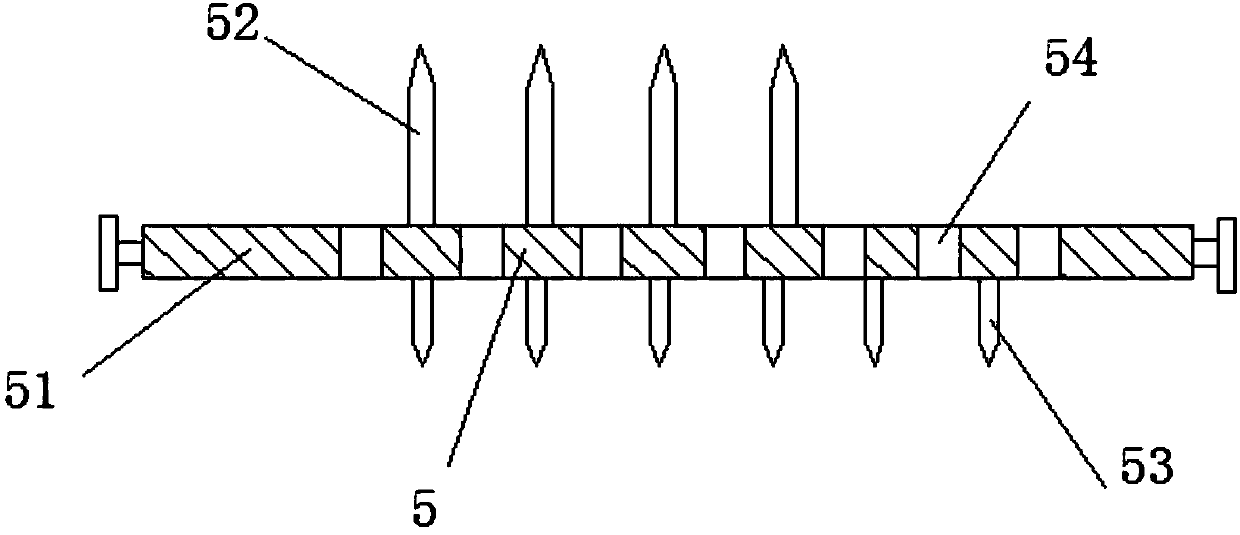

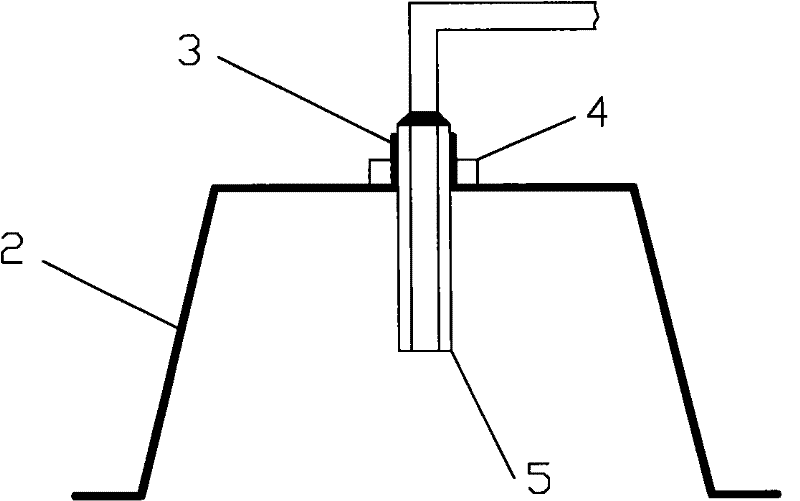

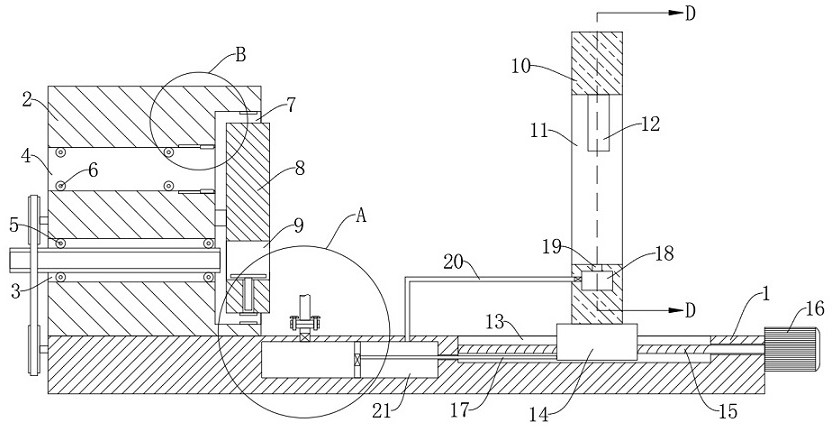

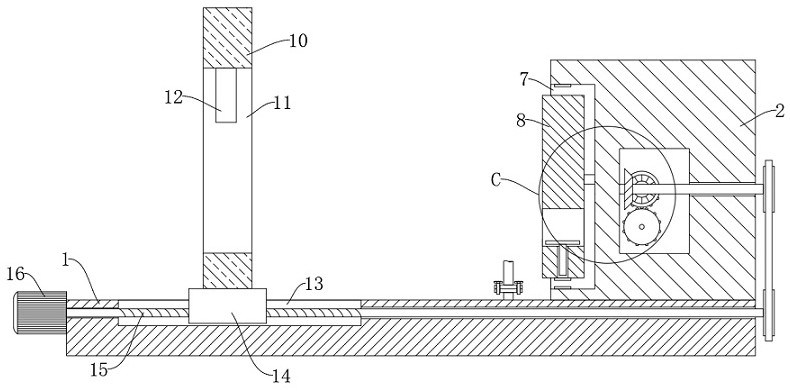

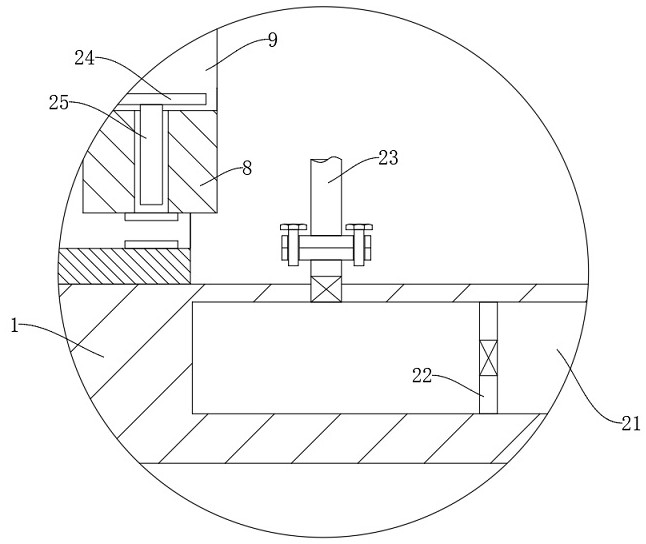

A comprehensive test device for anti-clogging performance of drip irrigation emitters

InactiveCN102288396AImprove synchronicityImprove self-cleaning functionMachine part testingDrip irrigationEngineering

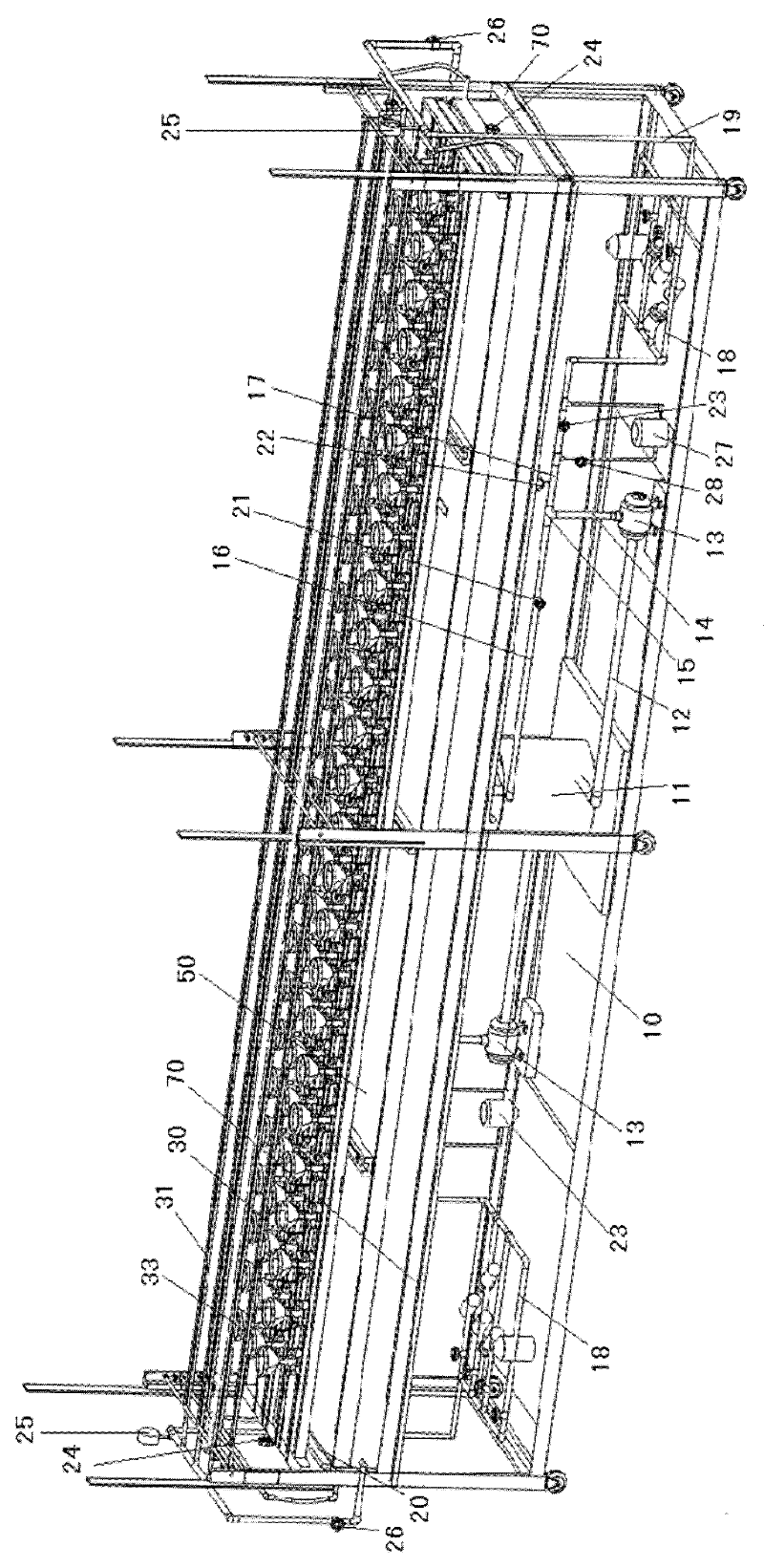

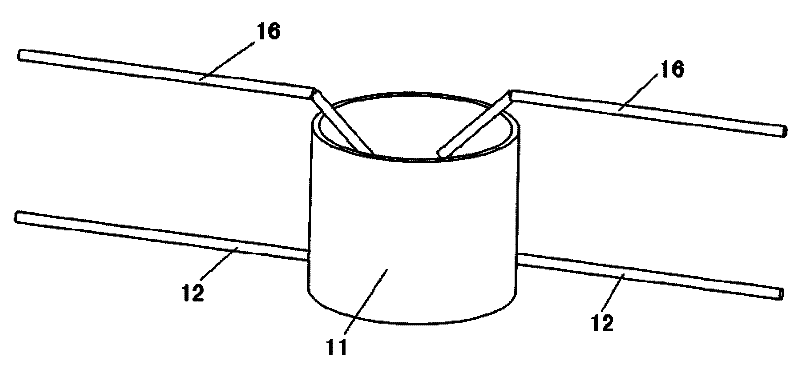

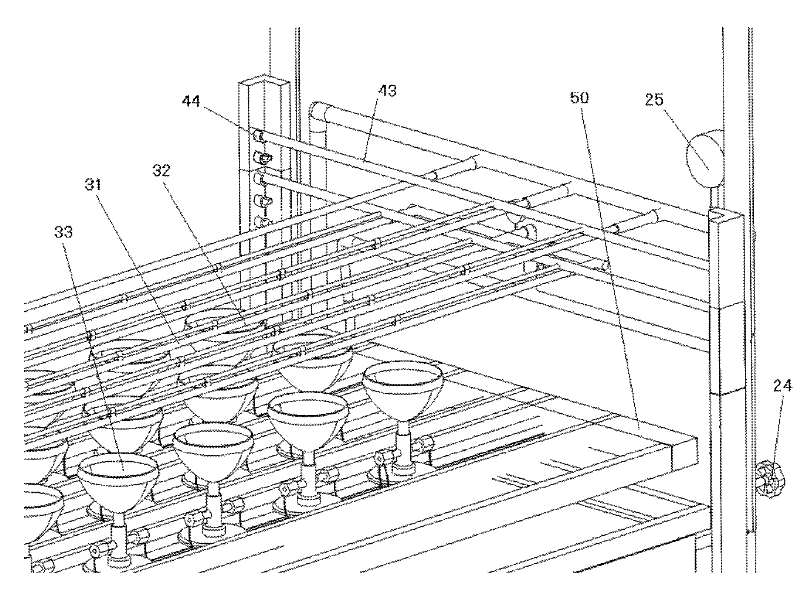

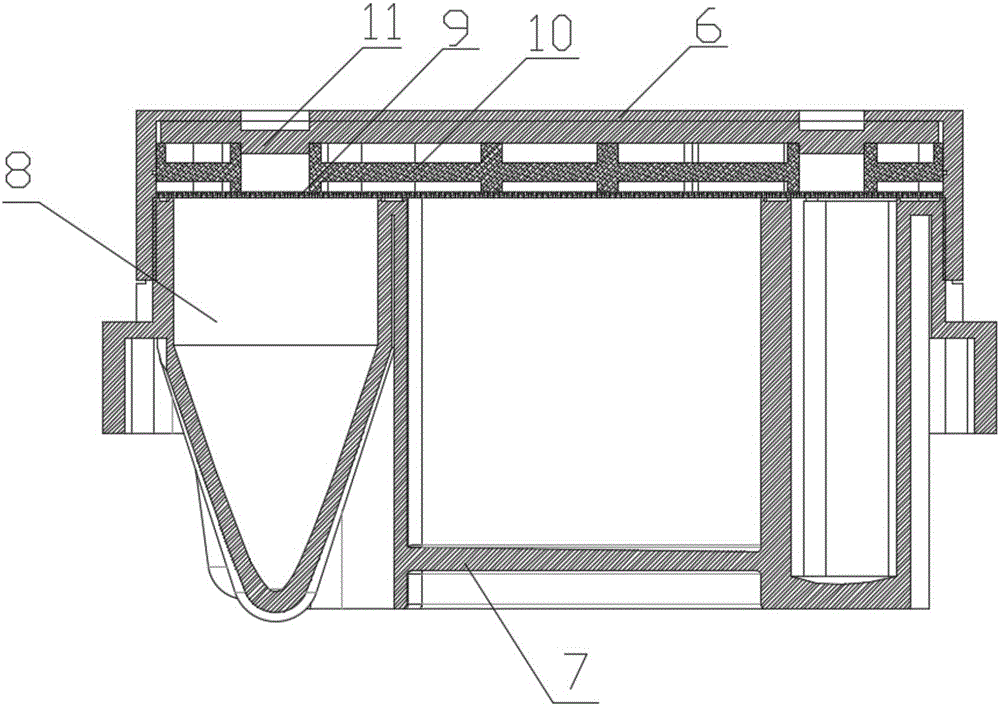

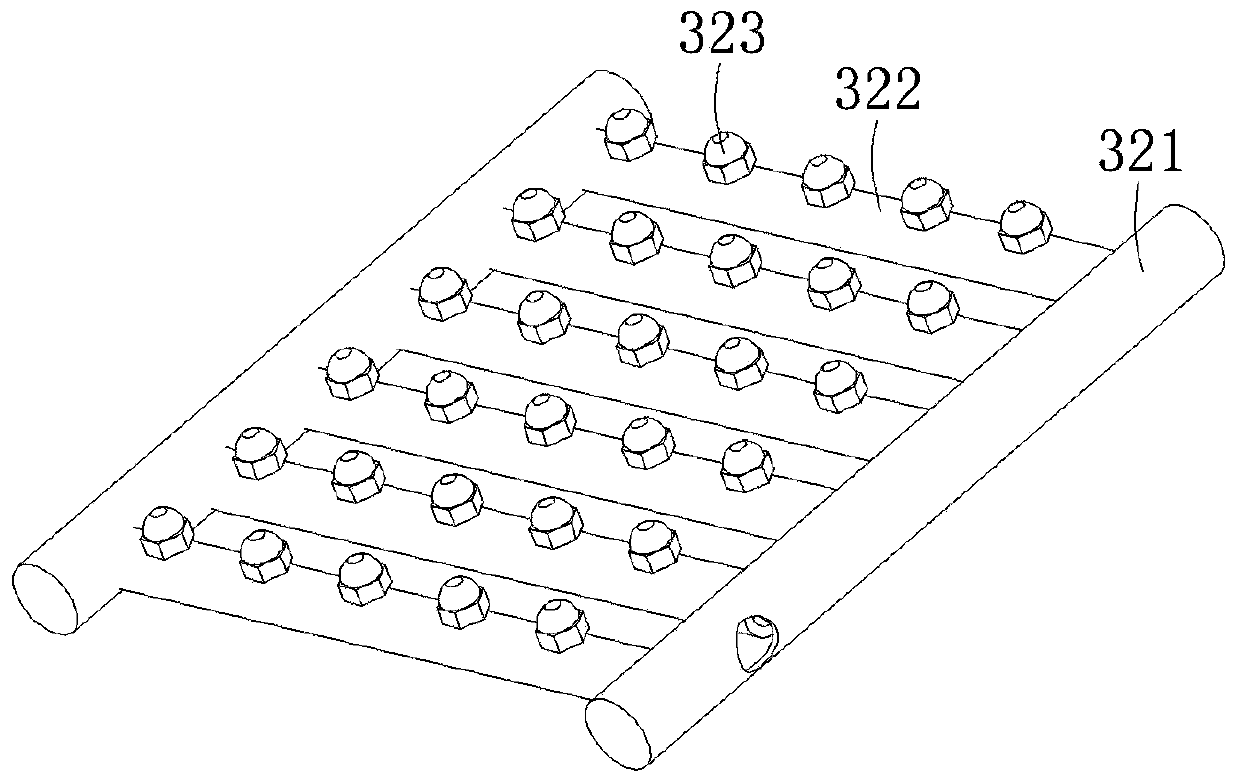

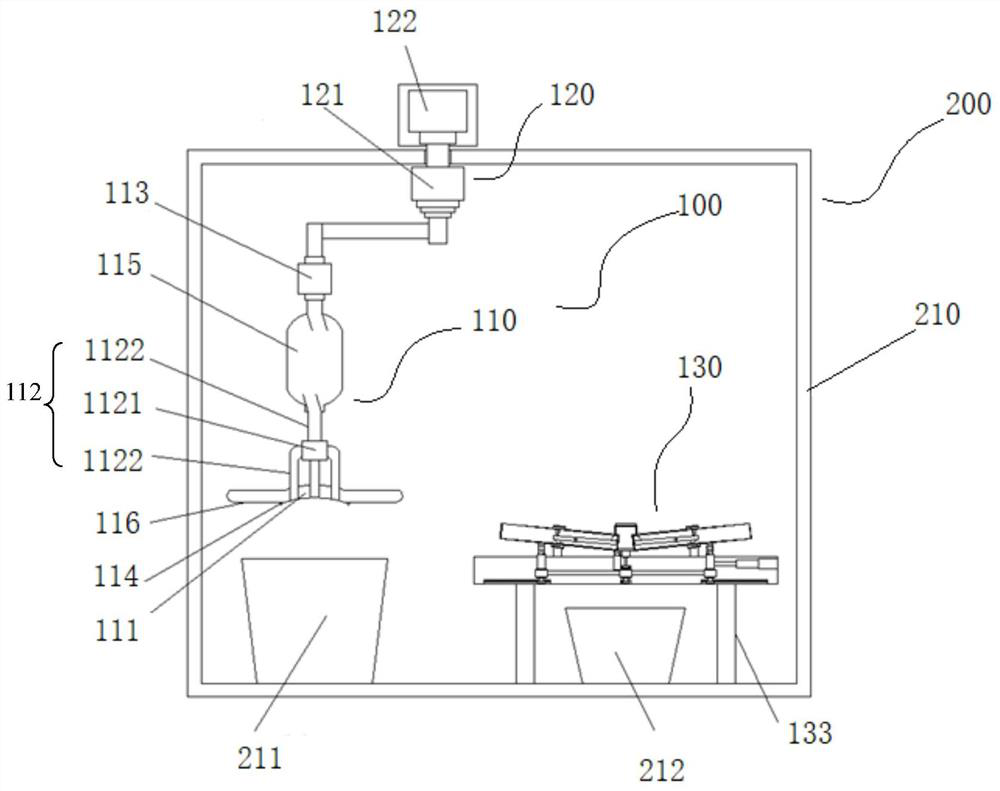

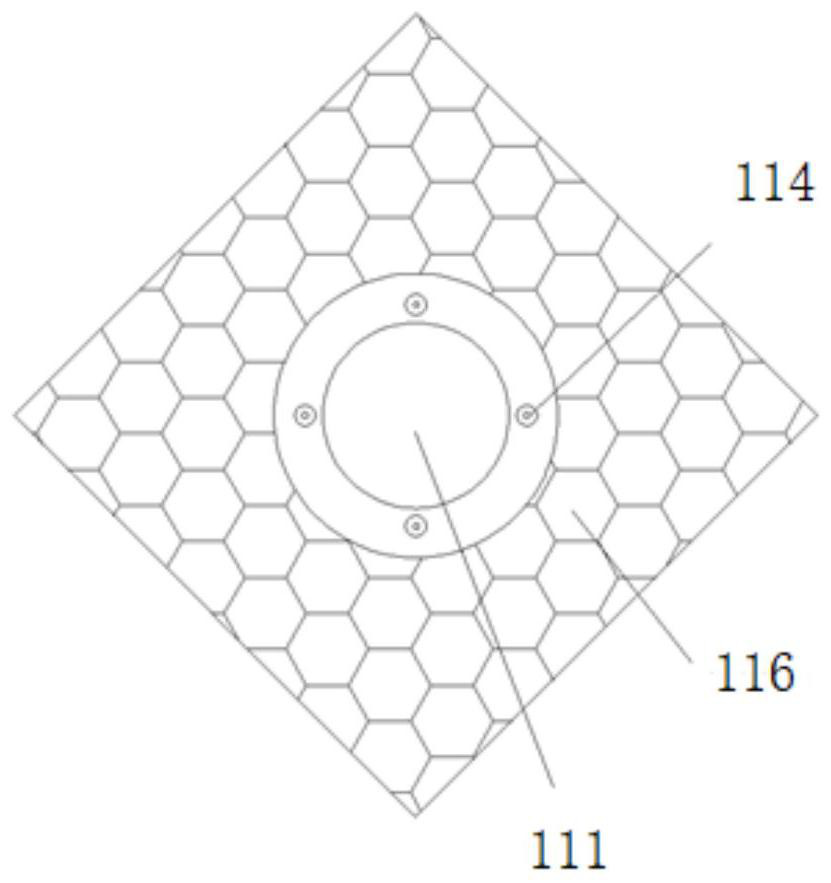

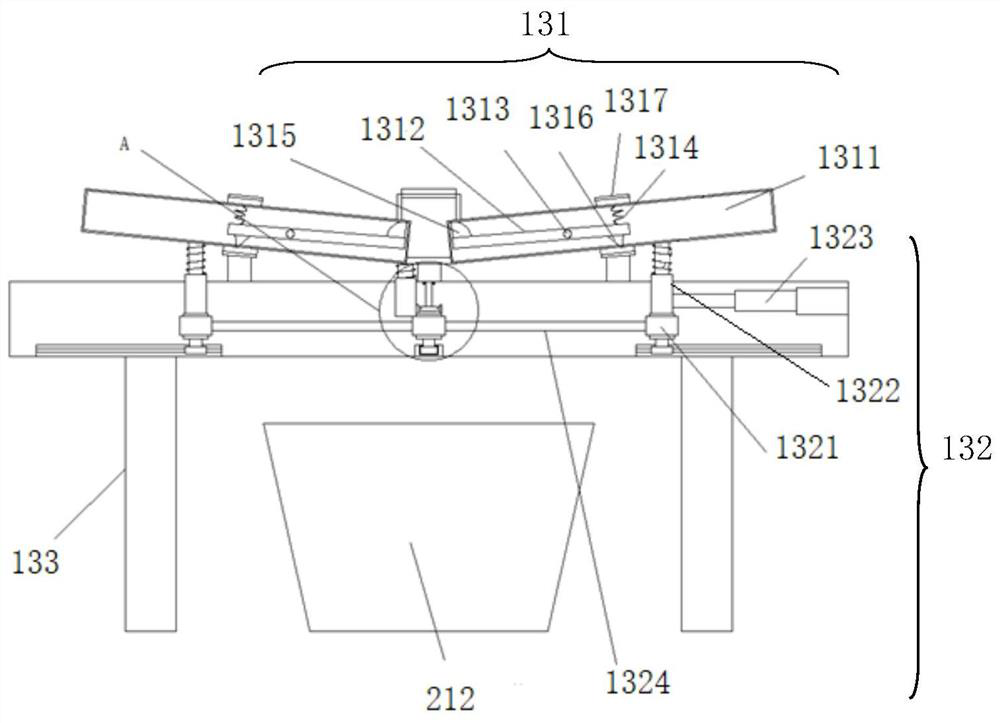

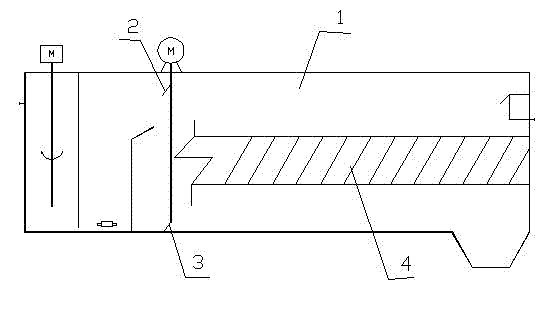

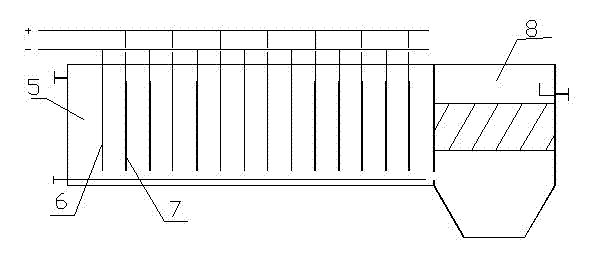

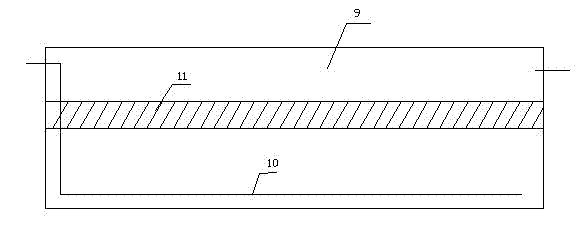

The invention relates to a comprehensive testing device for the anti-clogging performance of drip irrigation emitters. The comprehensive testing device is characterized by comprising a frame, wherein a water supply system is arranged below the frame; a drip irrigation system is arranged above the frame; a composite moving device is arranged below the drip irrigation system; a water collecting tank is arranged under the composite moving device; the water supply system comprises an adjusting water tank; a water pump suction pipe is arranged on the side face of the adjusting water tank; the other end of the water pump suction pipe is connected to a water pump; the water outlet pipe of the water pump is connected to primary shunt pipes and secondary shunt pipes respectively; the primary shuntpipes extend into the adjusting water tank respectively; the tail ends of the secondary shunt pipes are connected to a filter bank respectively; the filter bank is connected to the drip irrigation system respectively; the drip irrigation system comprises a drip irrigation pipe, a plurality of drip irrigation emitters and a plurality of water holding units; and the water holding units are arrangedon the top of the composite moving device. The comprehensive testing device can be used for solving the problems of single function, low intelligent degree, not high test accuracy and the like of thepreceding anti-clogging performance testing device, and can be widely applied to the comprehensive test of the anti-clogging performance of the drip irrigation emitters.

Owner:CHINA AGRI UNIV

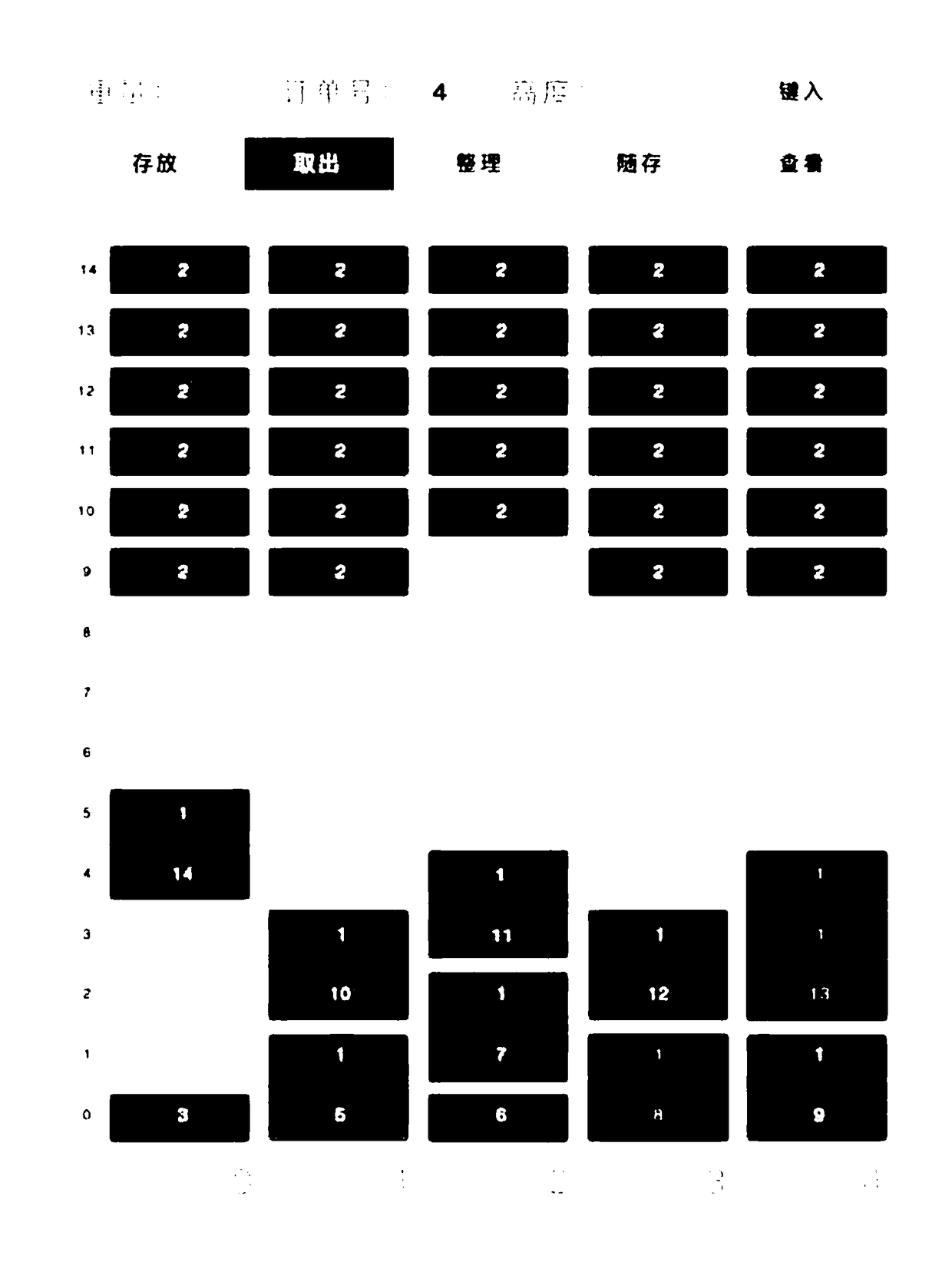

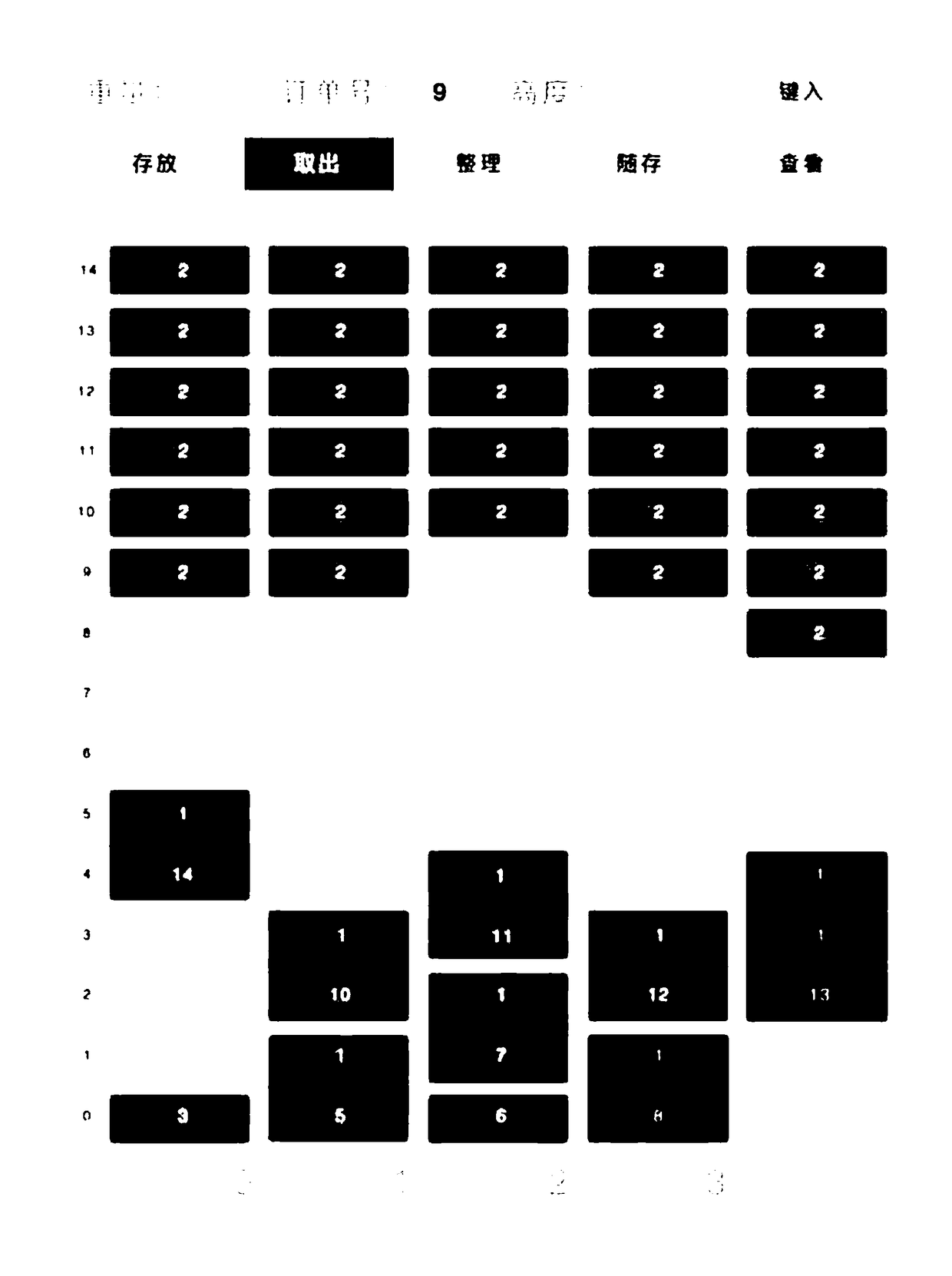

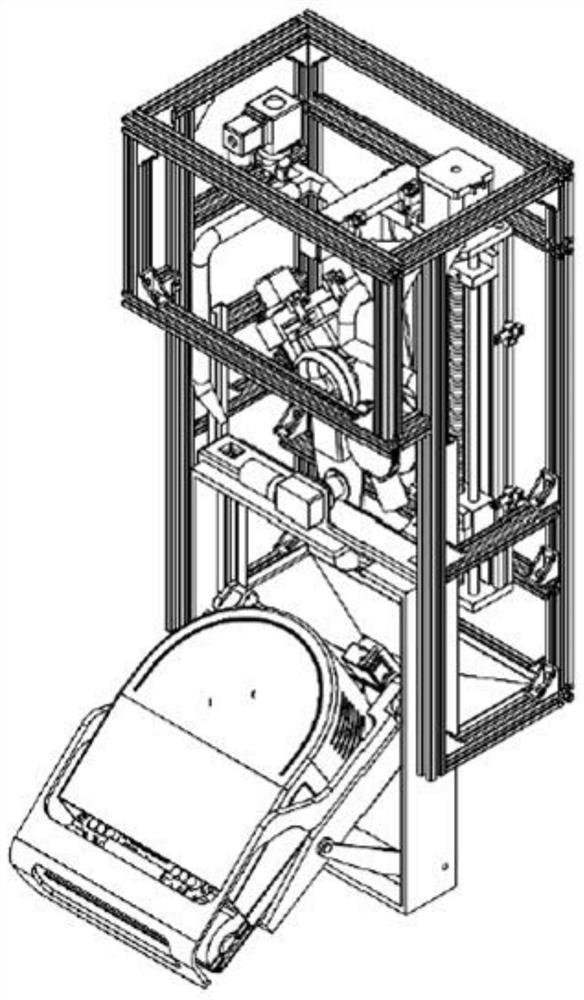

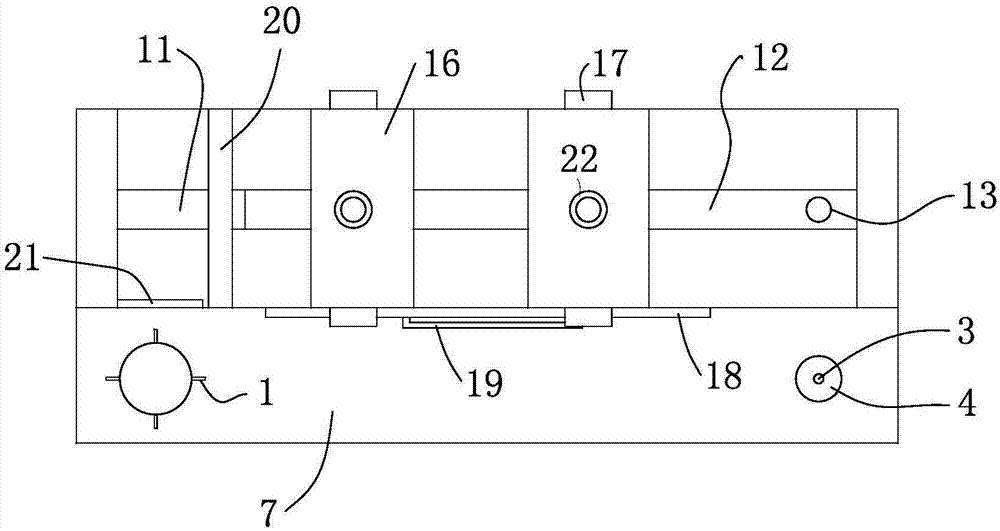

Smart express cabinet and using method thereof.

ActiveCN108074356AFully automatic processingIncrease storage spaceCoin-freed apparatus detailsApparatus for meter-controlled dispensingPlate columnEngineering

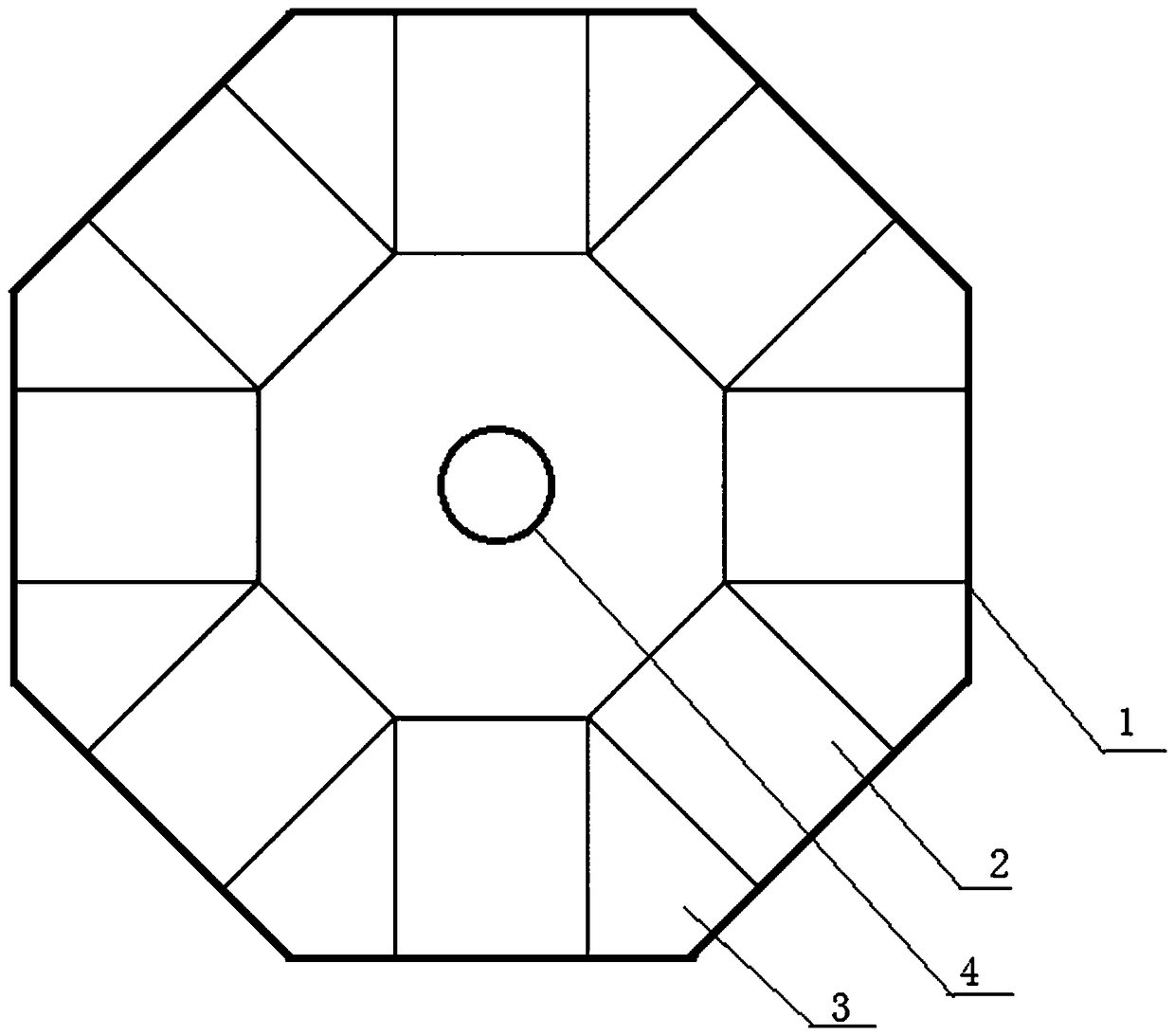

The invention relates to a smart express cabinet and a using method thereof. The express cabinet comprises a cabinet body, trays, inserting plate columns arranged inside the cabinet body and used forsupporting the trays, a mechanical hand moving device, a scanning device and a main control machine. The cabinet body is of a regular prismatic structure and is internally provided with a cavity. Oneside of the cabinet body serves as a cabinet door, and the cabinet door is provided with an article access port. The inserting plate columns are located between two adjacent side faces of the cabinetbody, and the opposite side faces of two adjacent inserting plate columns are provided with evenly-distributed horizontal grooves respectively. The trays are inserted into the horizontal grooves and are perpendicular to the side of the cabinet body, and a plurality of height-adjustable storage compartments are formed by changing the insertion positions of the trays to provide physical storage locations for stored articles. The mechanical hand moving device is connected with a main control computer and used to move the trays. The scanning device is mounted at the position of the article accessport and used to obtain specifications of a stored article. The smart express cabinet achieves full-automatic processing after express articles enter the express cabinet without manual intervention ofthe storage location, and a storage space is automatically adjusted and optimized.

Owner:XIAMEN UNIV TAN KAH KEE COLLEGE

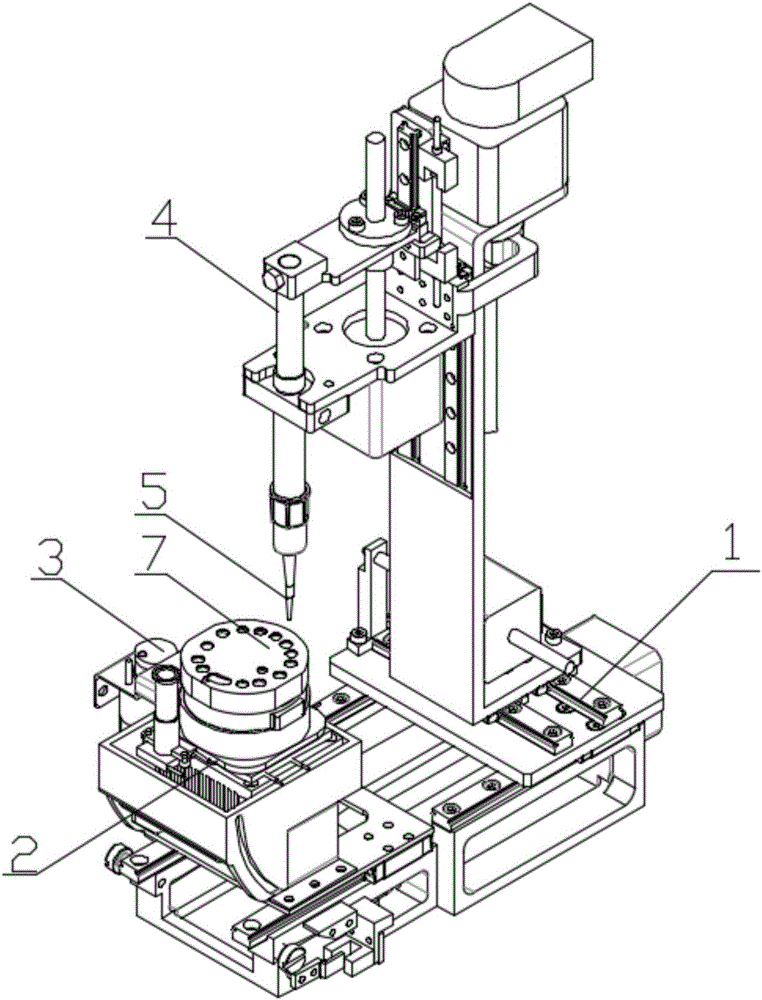

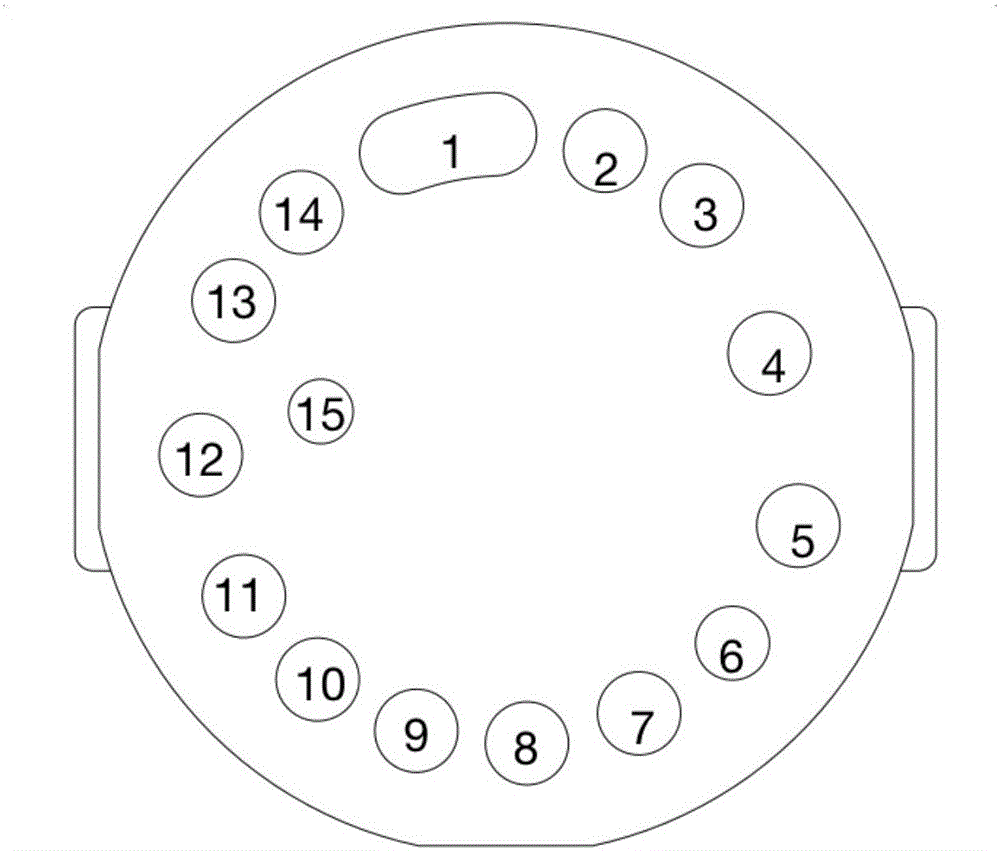

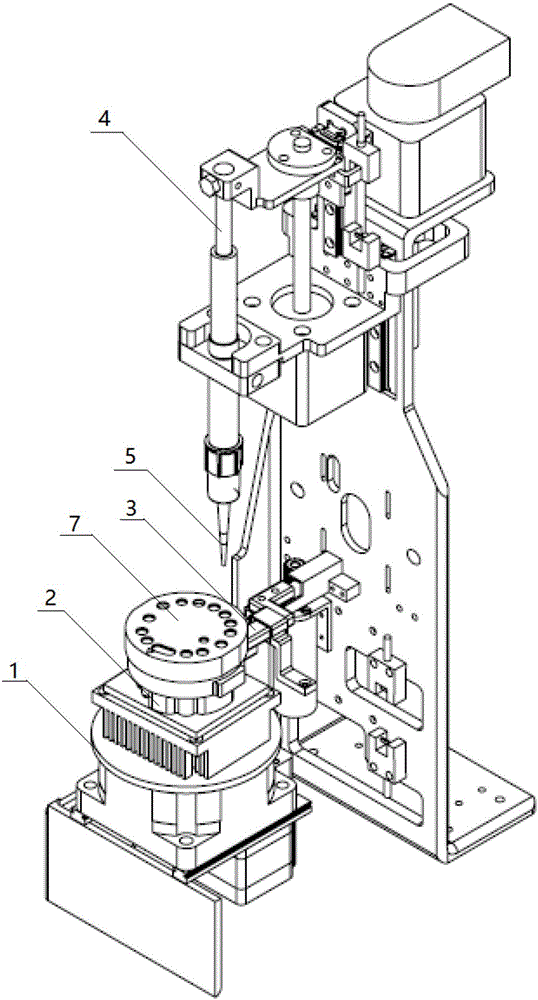

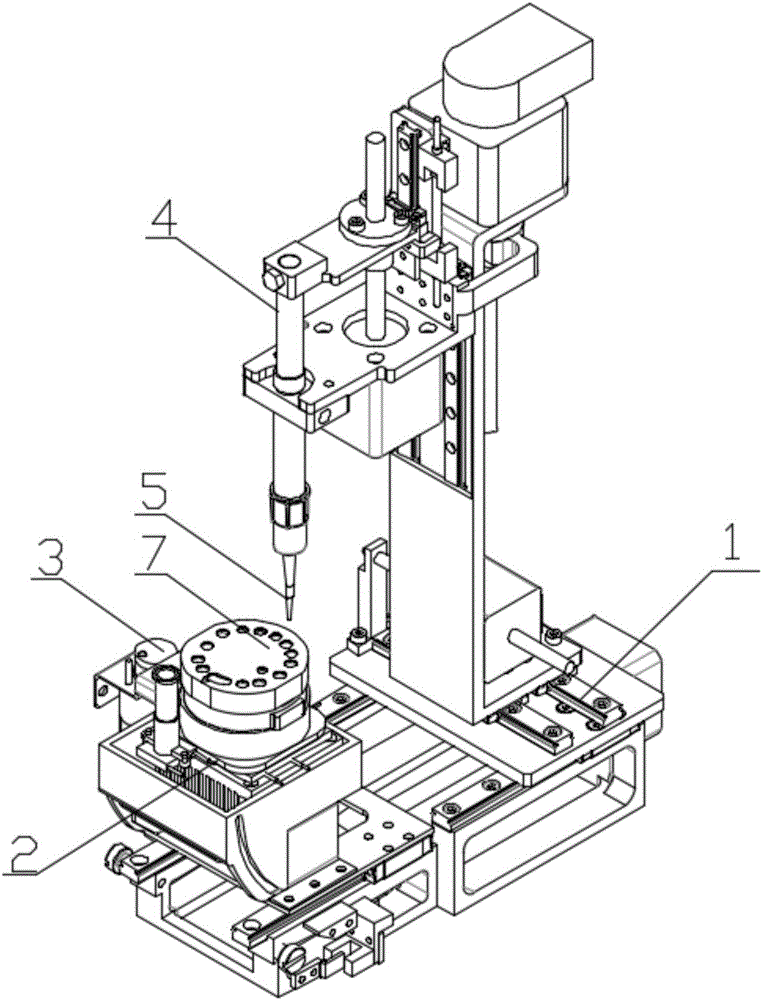

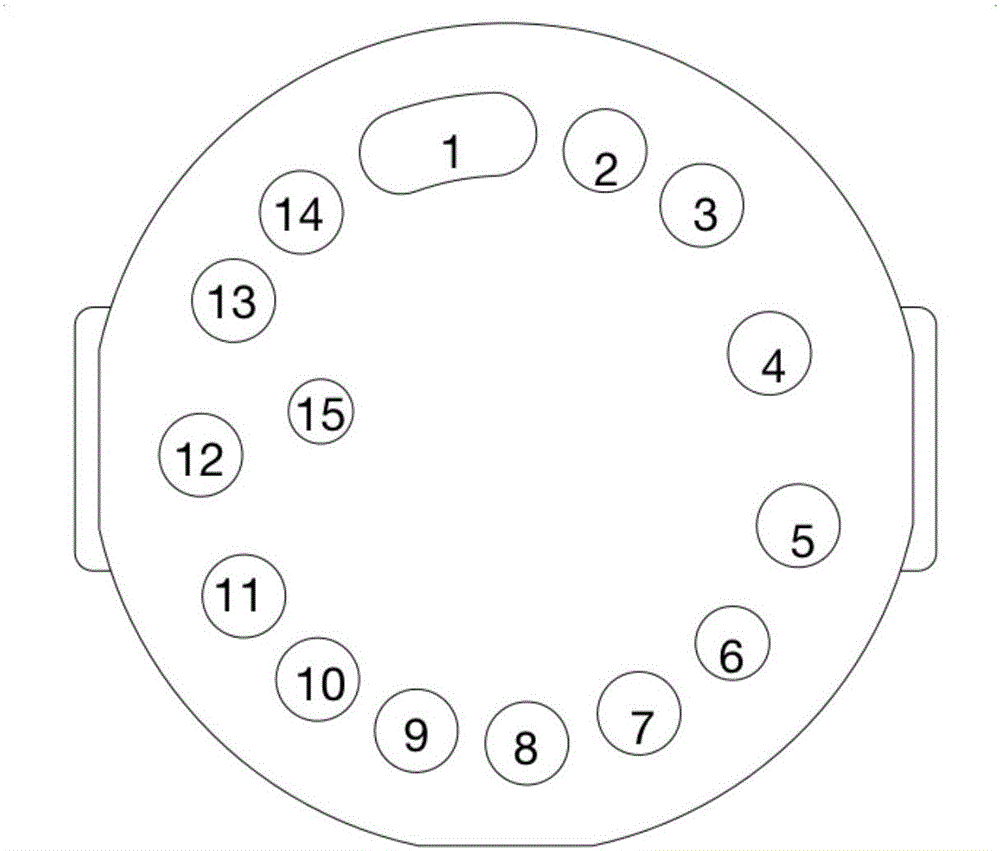

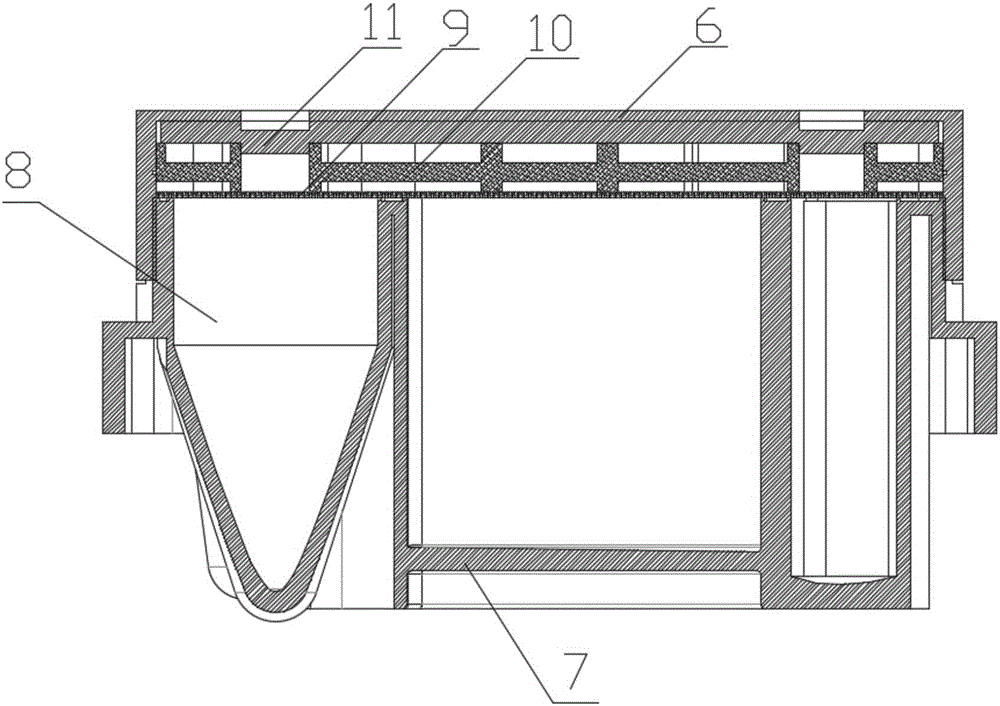

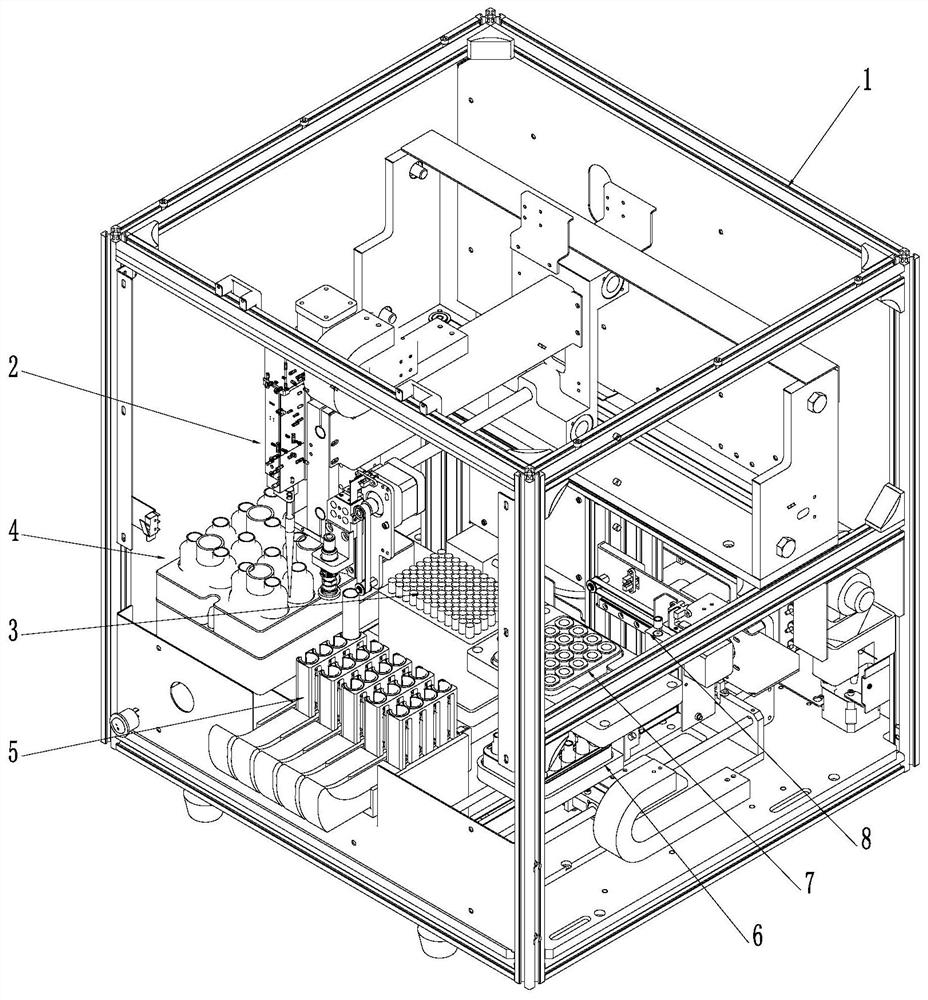

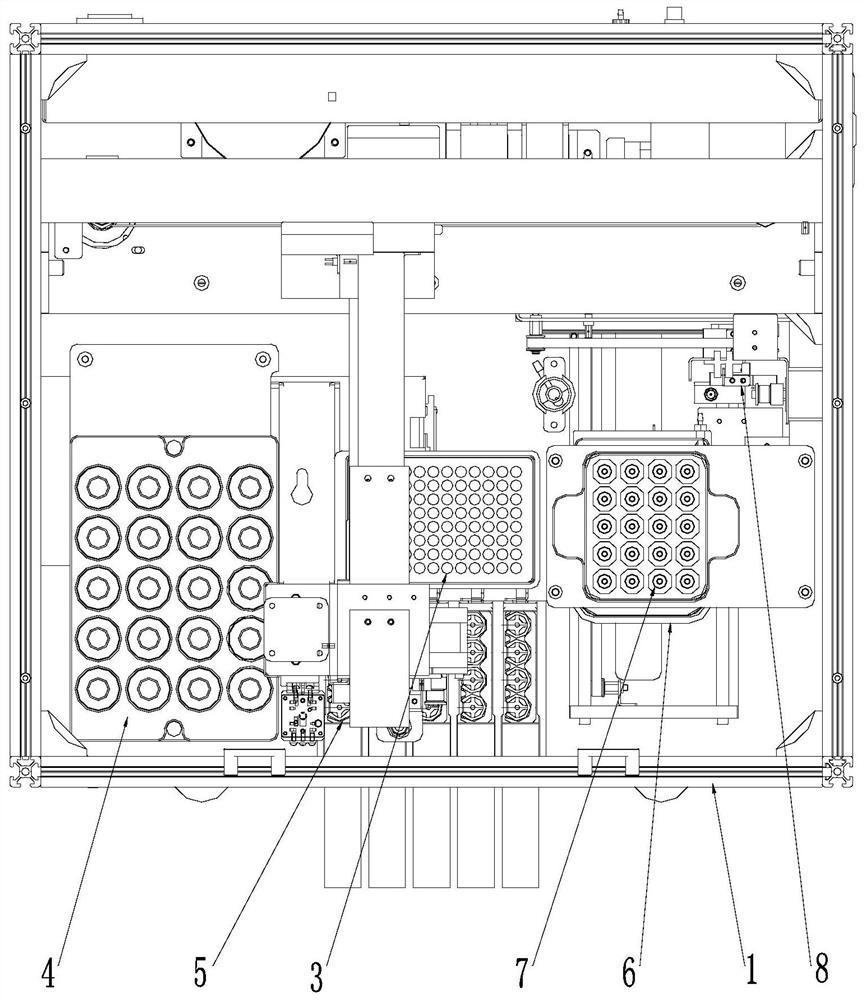

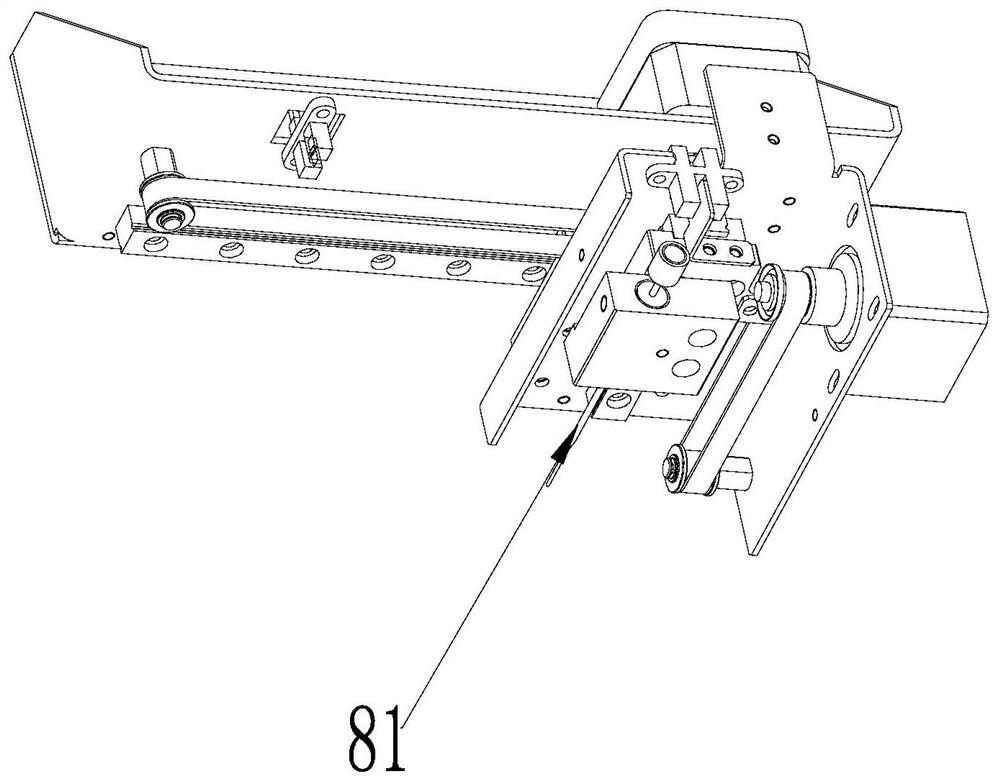

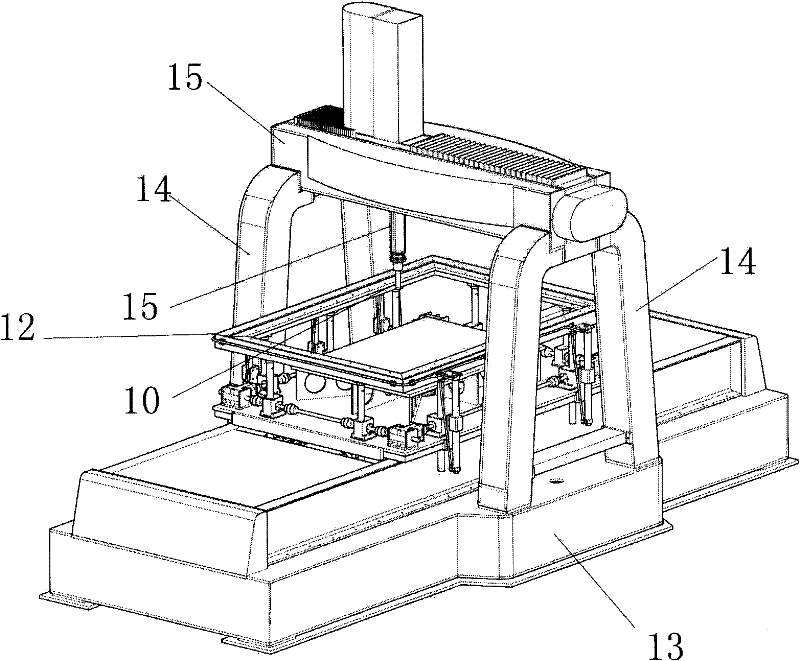

Nucleic acid detection pretreatment automation device

PendingCN106404508AAchieving Simultaneous DetectionAvoid confusionPreparing sample for investigationTemperature controlNucleic acid detection

The invention discloses a nucleic acid detection pretreatment automation device. The device is characterized by comprising a reagent disc for placement of a sample and a pretreatment reagent, a base for placement of the reagent disc, a magnetic separation module for realizing separating, cleaning and eluting of magnetic particles, a liquid transferring device for transferring the reagent in the reagent disc, a moving guide rail platform for supporting the liquid transferring device and a host for controlling a temperature control module, a rotating module, a well-mixing module, the magnetic separation module and the liquid transferring module to run; the temperature control module and the well-mixing module are arranged on the base, and the liquid transferring device is provided with a liquid transferring module, the rotating module and a liquid transferring gun head. The nucleic acid detection pretreatment automation device can realize full automation of nucleic acid detection pretreatment including extraction, library construction and product purification, a final product can be directly used for high-throughput sequencing, and the whole process is unmanned.

Owner:HANGZHOU GENE META MEDICAL DEVICE CO LTD

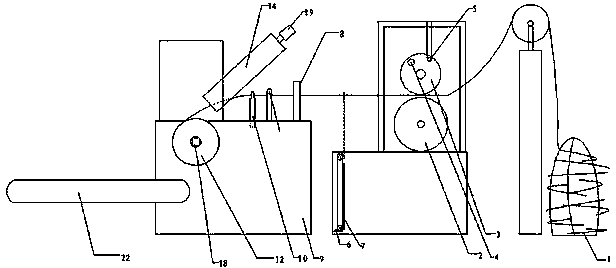

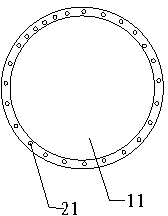

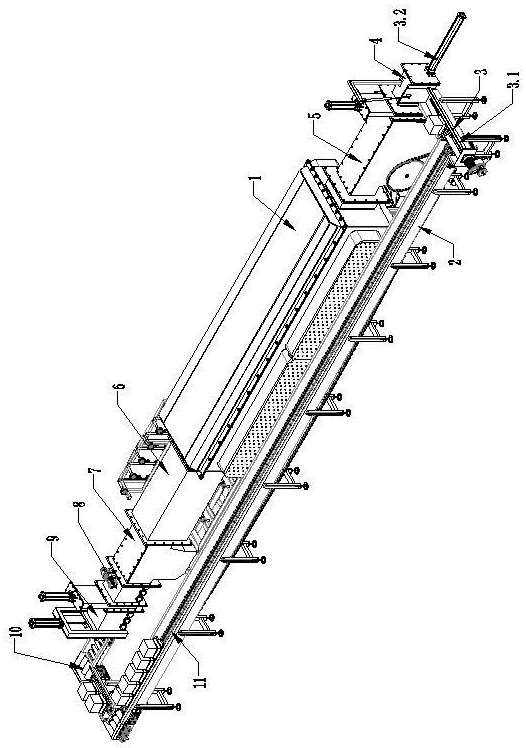

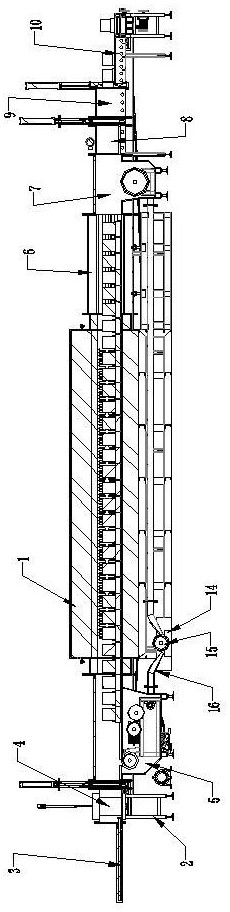

Full-automatic coil winding mechanism for outputting cable

InactiveCN103935824AGuaranteed uptimeFully automated processingFilament handlingWinding machineConductor Coil

The invention provides a full-automatic coil winding machine for outputting a cable. The full-automatic coil winding mechanism for outputting the cable comprises a pay-off frame, a counting guiding cutting device, a coil winding machine and a PLC. After the cable penetrates through the counting guiding cutting device through the pay-off frame, the cable is connected with the coil winding machine for coil winding. The whole full-automatic coil winding mechanism is automated through control of the PLC. The full-automatic coil winding machine for outputting the cable is simple in structure, reasonable in design, capable of achieving full-automatic processing from pay-off to coil winding, free of manual operation, low in labor investment, low in cost and capable of greatly improving economical benefits and improving the product quality.

Owner:STATE GRID CORP OF CHINA +3

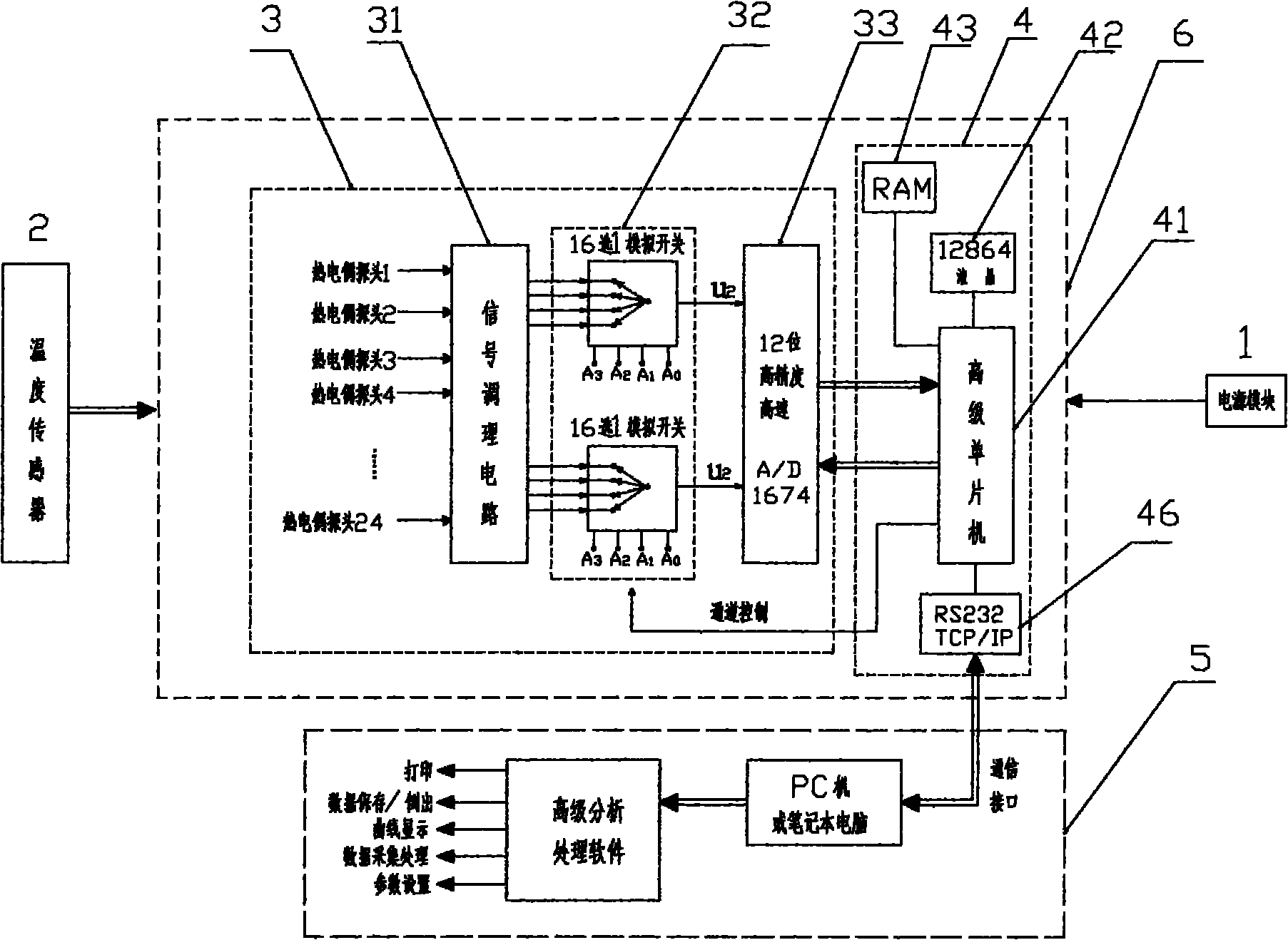

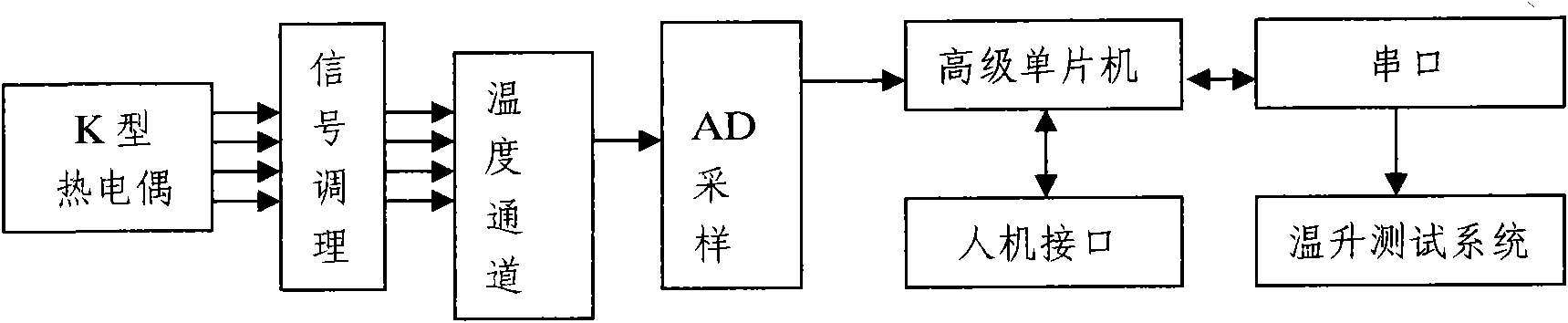

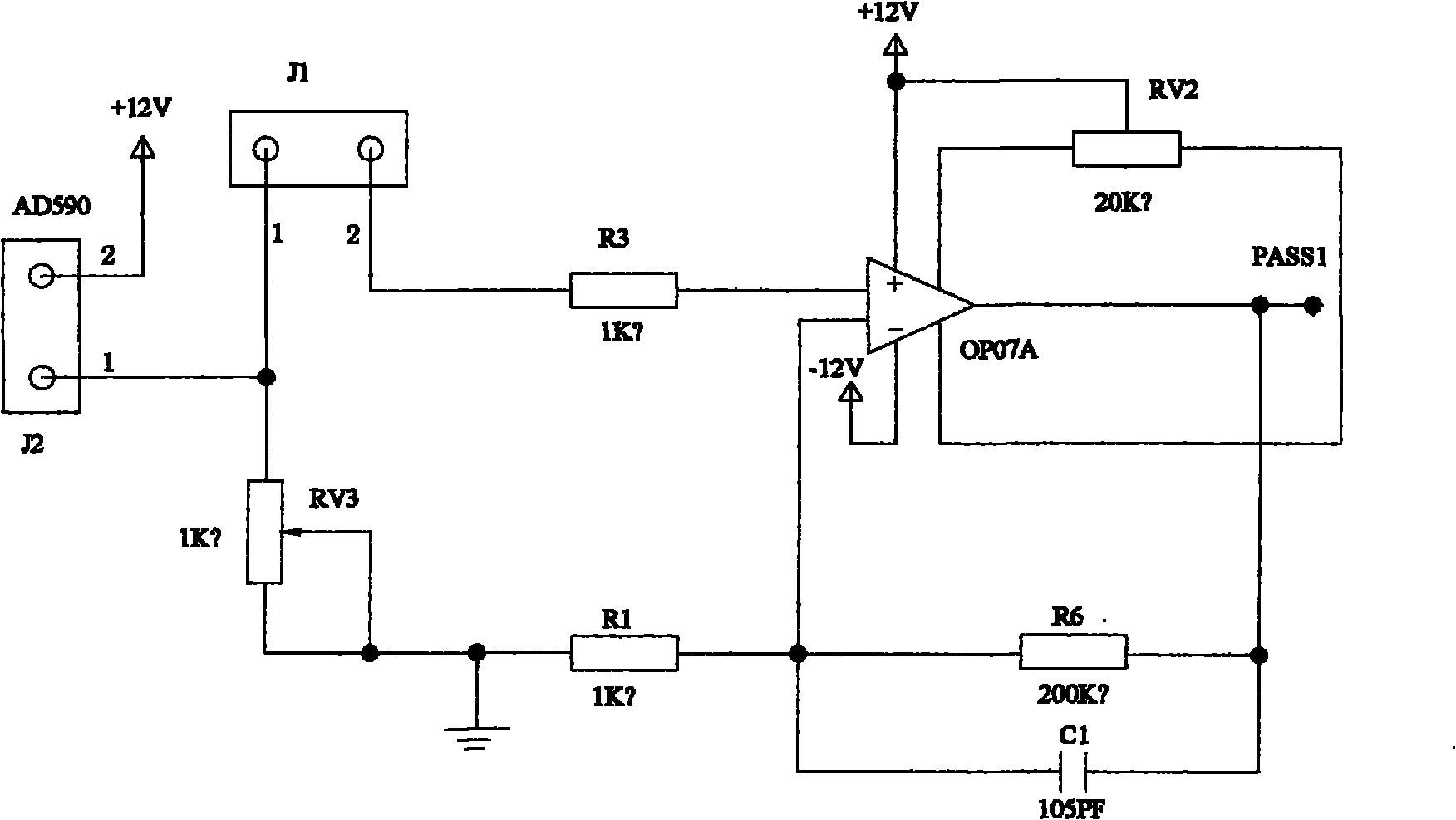

Virtual program control temperature test instrument

InactiveCN101881671ASimple test formatImprove accuracy and reliabilityProgramme controlComputer controlInstrumentationTest report

The invention discloses a virtual program control temperature test instrument and belongs to the technical field of mechanical and electrical product test. The instrument mainly comprises an upper computer, a power supply module, a temperature sensor, a signal conditioning module, a singlechip and a serial port server, wherein the temperature sensor consists of a 24-path K-type thermal electric couple; a signal acquired by the thermal electric couple is amplified by the signal conditioning module and is subjected to cold junction compensation and A / D conversion to generate a temperature digital signal to be stored in the internal memory of the singlechip; a temperature value is transmitted to the serial port server through a serial port of the singlechip; and the serial port server converts a serial port signal into an Ethernet signal so as to realize remote communication with the upper computer. The software of the upper computer automatically judges whether temperature rise is accordant with a standard and realizes setting of a temperature acquisition frequency, the definition of a temperature channel, real-time display of a temperature test value, drawing of a temperature curve and automatic generation of a test report. The test instrument has a simple test form, can improve the intellectuality, accuracy and reliability of a system and meets the requirements of current networked tests.

Owner:WUXI ENTRY EXIT INSPECTION & QUARANTINE BUREAU PEOPLES REPUBLIC OF CHINA

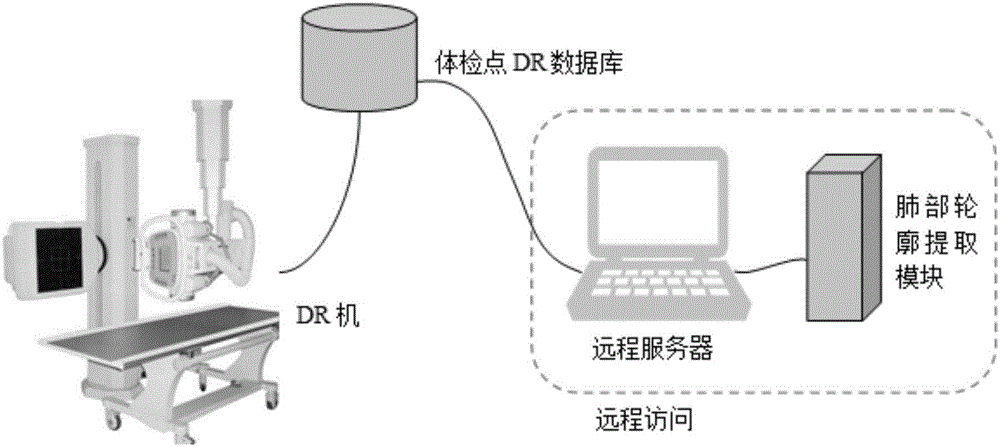

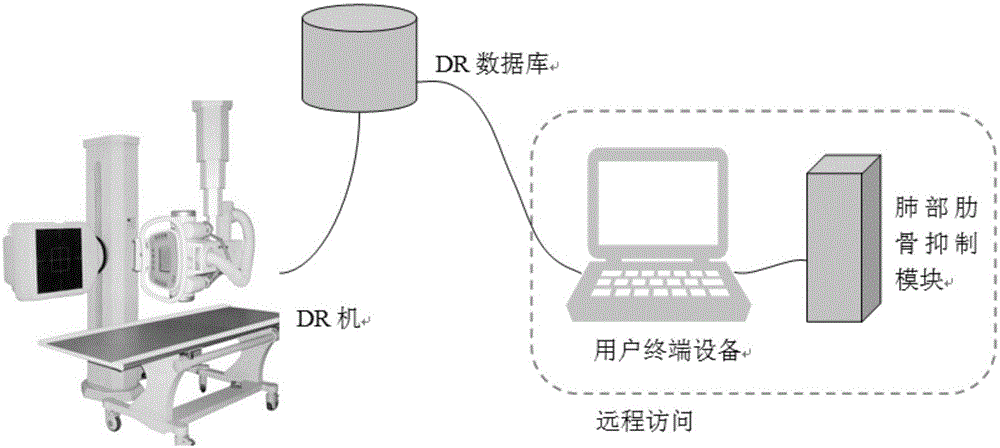

Method for extracting lung lobe contour from DR image

ActiveCN106408024ATargetedReduce visual loadImage enhancementImage analysisDiseasePattern recognition

The invention discloses a method for extracting a lung lobe contour from a DR image. The method comprises the following steps: a representative template of a lung lobe contour is obtained through offline training; a chest DR image lung lobe area extraction system is initialized; according to the size of a DICOM image, the image is subjected to three-layer pyramid decomposition; a Gabor filter set is used to reconstruct the to-be-processed image, and the residual error of the reconstructed image after Gabor filter is converted into a black and white image; the black and white image is refined with a Zhan-Suen refinement algorithm; with each offline training template called as a convolution kernel operator, the contour image is subjected to convolution; a local optimal convolution value of the optimal possibility is filtered out of the convolution results and subjected to combined evaluation; and a lung lobe contour shape is generated by combining the most matching upper and lower templates and the most matching positions. The method improves the work efficiency and inspection precision of lung disease inspection by doctors, supports further deepening the informatization of tuberculosis monitoring, and facilitates popularization of regular resident infectious disease examination screening of tuberculosis.

Owner:SICHUAN UNIV

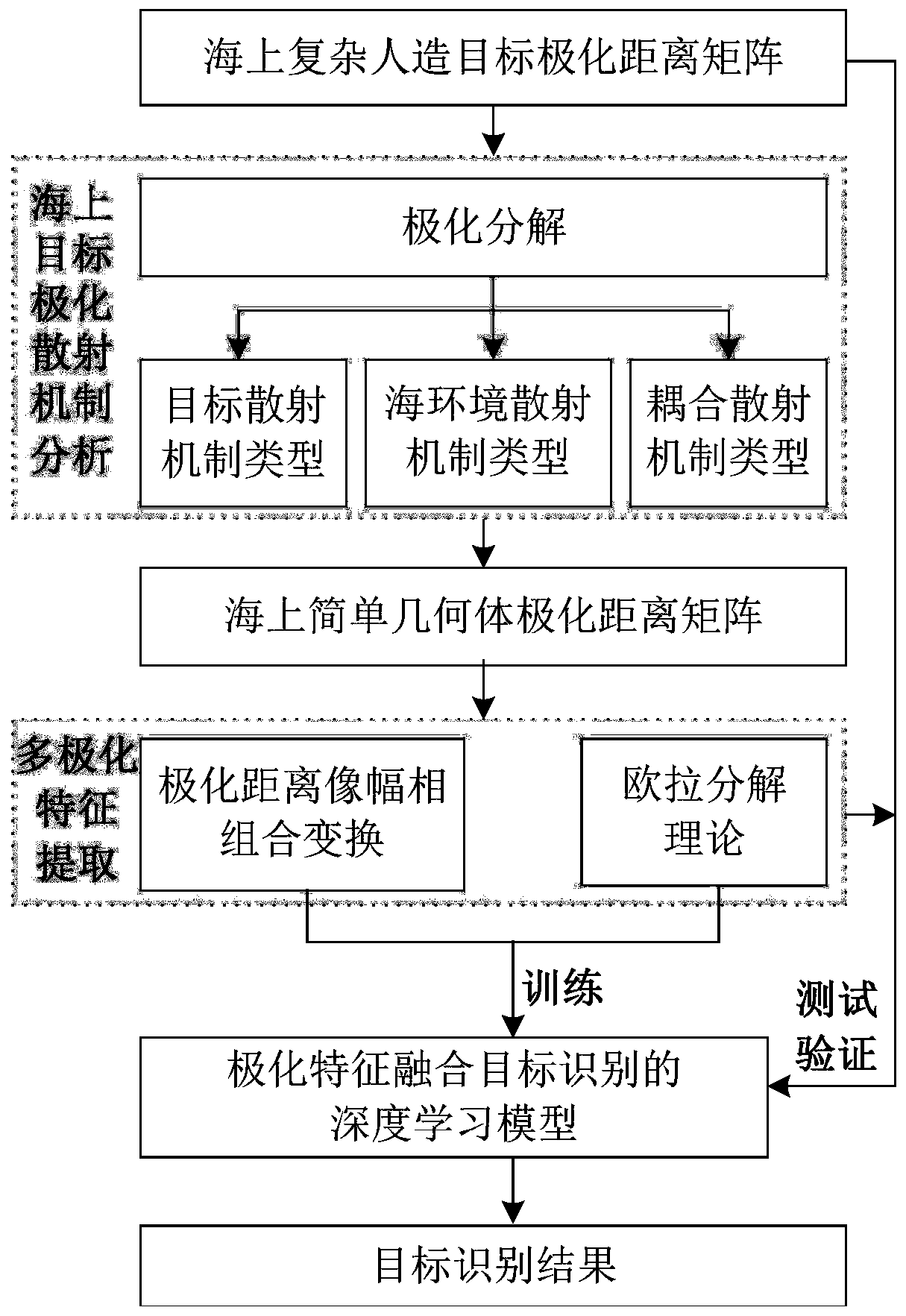

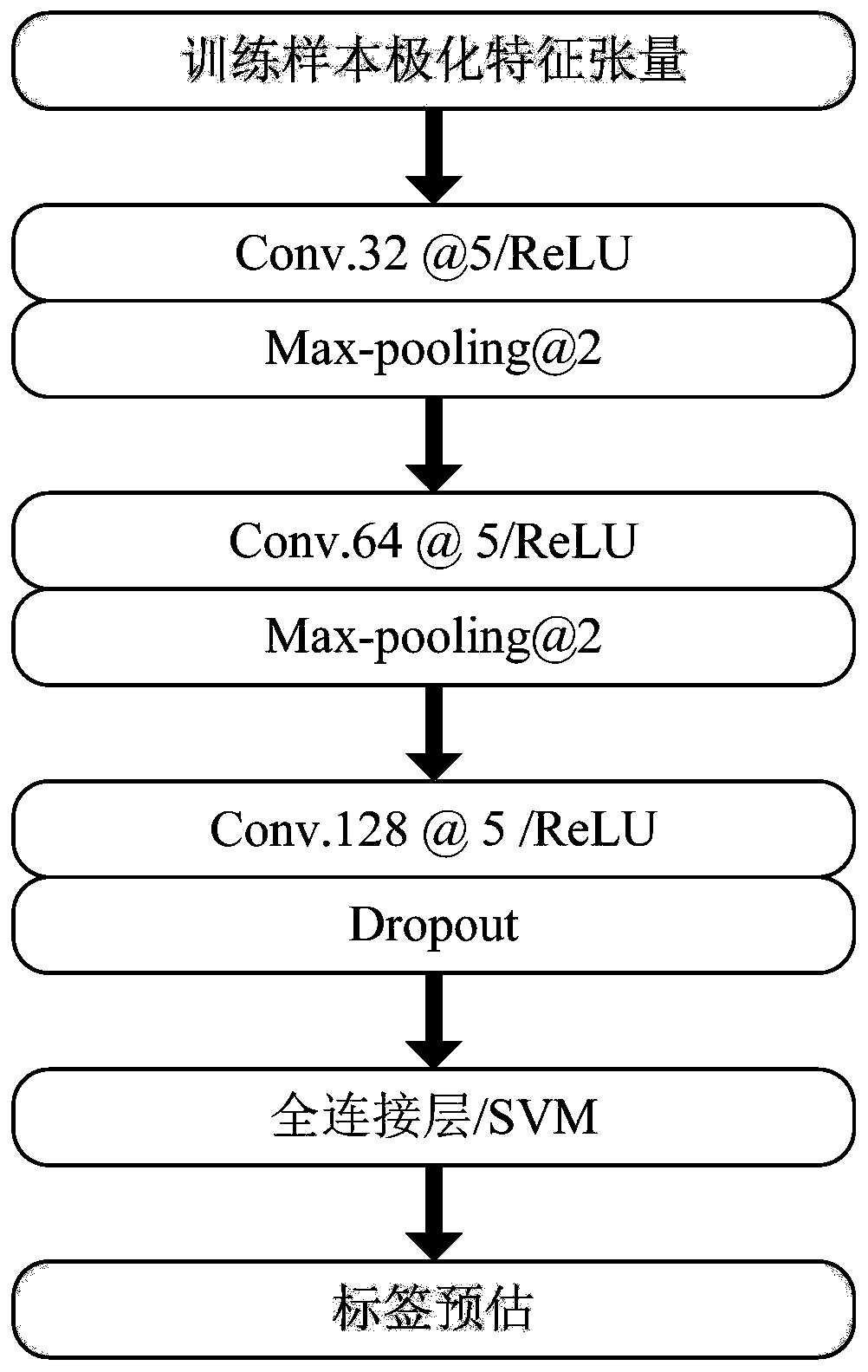

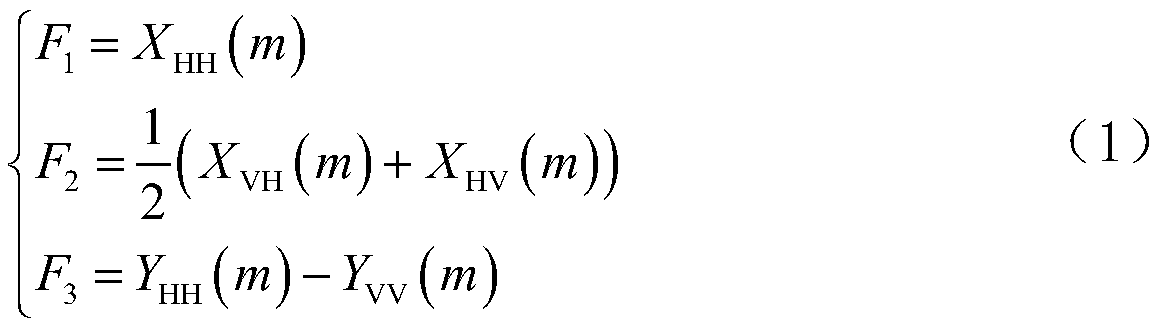

Polarization Euler feature fusion deep learning-based marine target identification method

ActiveCN110826643AHigh precisionReduce adverse effectsWave based measurement systemsCharacter and pattern recognitionData setAlgorithm

The invention discloses a polarization Euler feature fusion deep learning-based marine target identification method. The method comprises the following steps of S1, analyzing a polarization scatteringmechanism of a marine artificial target; S2, based on the analysis result of the step S1, constructing a corresponding offshore geometry polarization distance matrix data set, and performing multi-polarization feature extraction on the samples of the polarization distance matrix data set; S3, based on the step S2, training a multi-polarization feature fusion deep learning model; and S4, carryingout identification, test and verification on the multi-polarization feature fusion deep learning model in the step S3 by adopting the offshore artificial target. The method has the advantages that themethod starts from the basic polarization scattering mechanism of the marine target, utilizes HRRP and polarization information to realize the target identification based on the deep learning fusion,eliminates the adverse effects caused by orientation sensitivity, improves the radar target identification precision, and has the advantages of high detection rate, low false alarm rate, flexible expansion application and full-automatic processing process.

Owner:SHANGHAI RADIO EQUIP RES INST

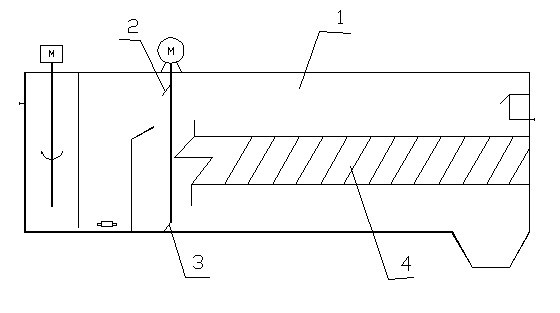

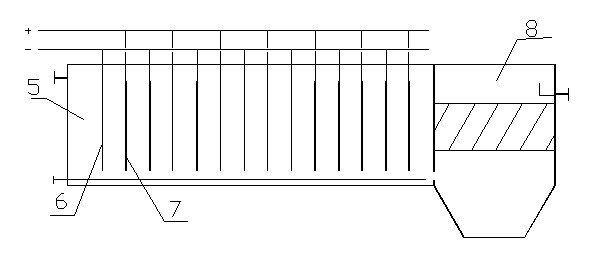

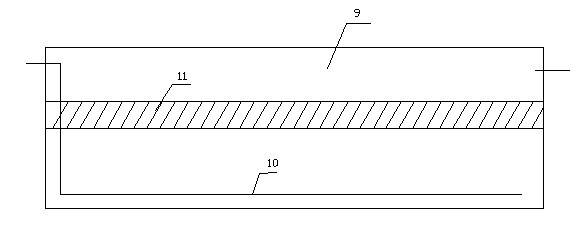

Coking waste water treatment method and A / O technology apparatus

InactiveCN102417272AThe cracking effect is goodImprove biological denitrification capacity and effectTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentWater treatmentHydrolysis

The invention is an improvement of a coking waste water treatment method. The method comprises steps of oil removal, impurity removal, electrolytic disintegration and A / O technology, and is characterized in that a biological hydrolysis acidification is set after electrolytic disintegration and before A / O technology; the electrolytic disintegration is electrode energizing aerobic strong electrolysis; the A / O technology employs butterfly jet aerators that are arranged in large intervals and have circulating pumps; the waste water is treated with aeration, aeration stopping and forced internal circulation, stationary deposition and water draining period processing successively, so as to realize biological oxidation and nitration-denitrification in a same pool. Cooperative effects and coordination of each technology increase treatment effect, and treated outlet water can stably reach COD no more than 100mg / l and NH3-N no more than 15 mg / l; besides, land occupation is saved undera same treating capacity and is only 80% of that of a common technology; operating cost of per ton of water is low; and a treatment effect is stable.

Owner:江苏新纯江环保工程有限公司

Automatic treatment device for pre-treatment of nucleic acid detection

PendingCN106754339AAchieving Simultaneous DetectionAvoid confusionBioreactor/fermenter combinationsBiological substance pretreatmentsPre treatmentChemistry

The invention discloses an automatic treatment device for pre-treatment of nucleic acid detection. The device is characterized by comprising a reagent disc for placing a sample and a pre-treatment reagent, a base for placing the reagent disc, a magnetic sorting module for separating, cleaning and eluting magnetic particles, a pipetting device for transferring the reagent in the reagent disc, and a host machine for controlling the temperature control module, the rotary module, the magnetic sorting module and the pipetting module to operate, wherein a temperature control module and a rotary module are arranged on the base; and the pipetting device is provided with a pipetting module and a pipetting gun head. The automatic treatment device for pre-treatment of nucleic acid detection disclosed by the invention can realize full automation of pre-treatment of nucleic acid detection. The pre-treatment comprises extraction, library construction and product purification. The final product can be directly used for high-throughput sequencing, and the device is of an unattended operation in the all course.

Owner:HANGZHOU GENE META MEDICAL DEVICE CO LTD

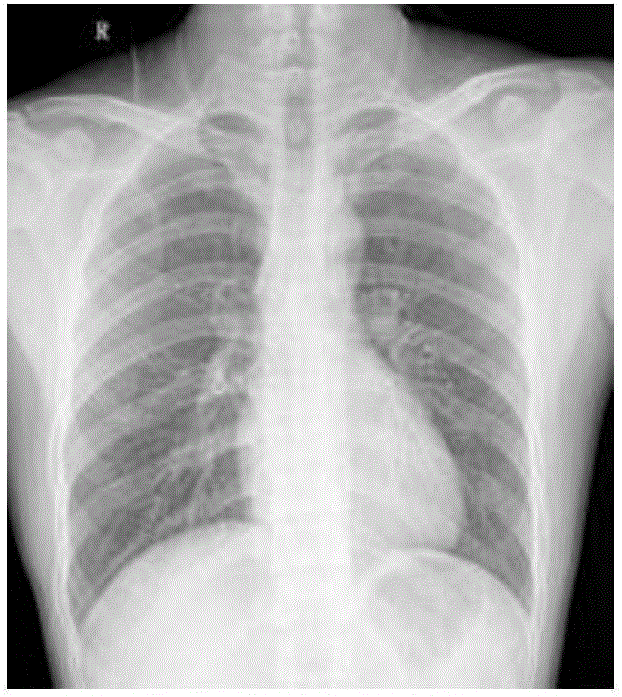

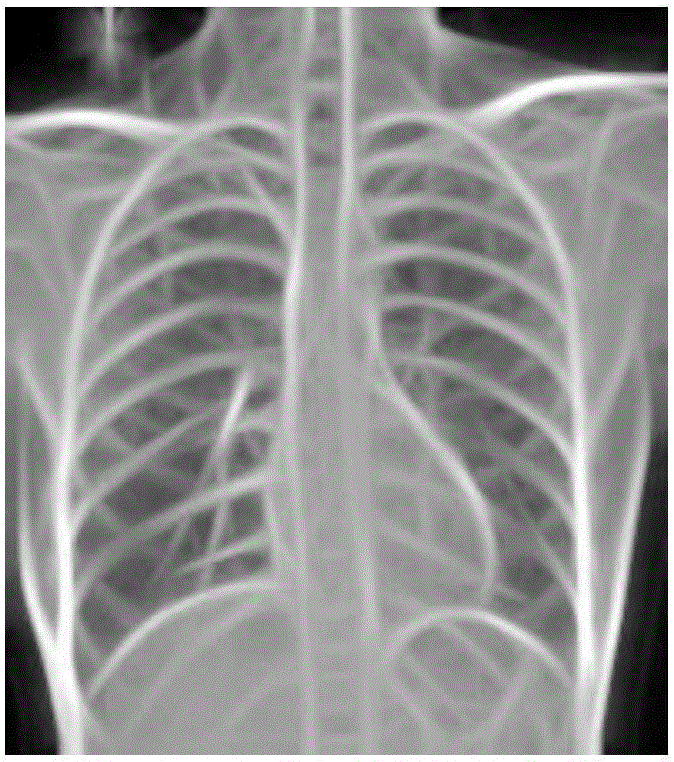

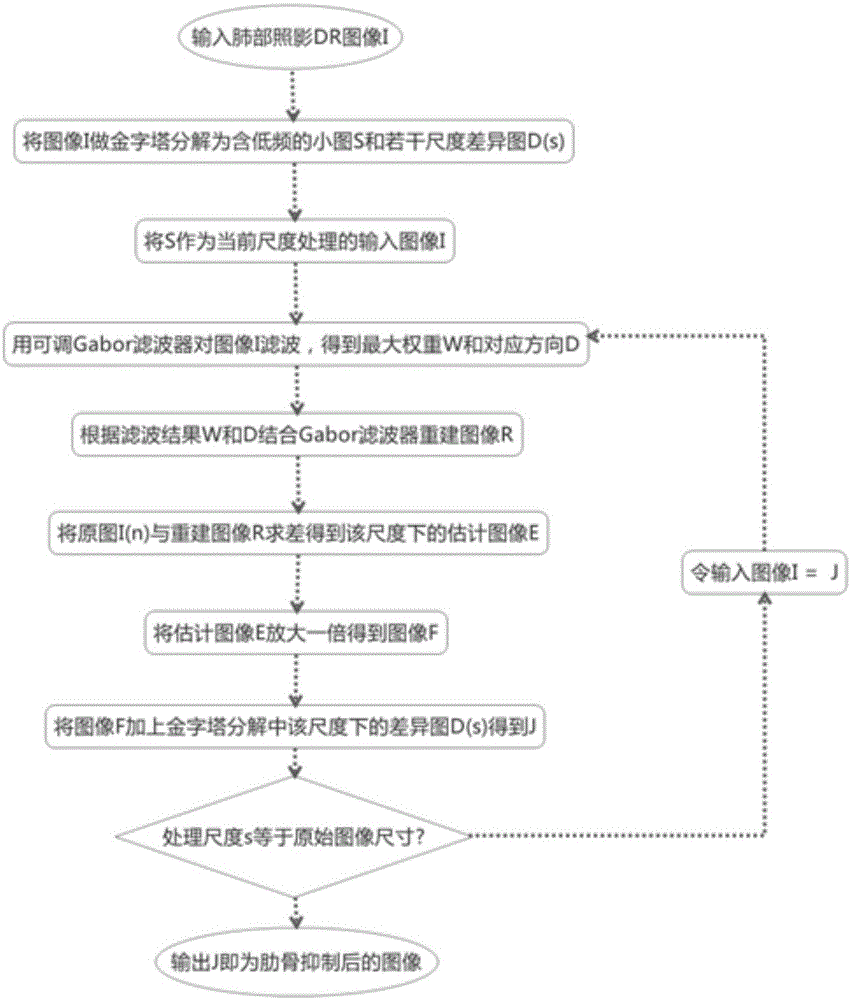

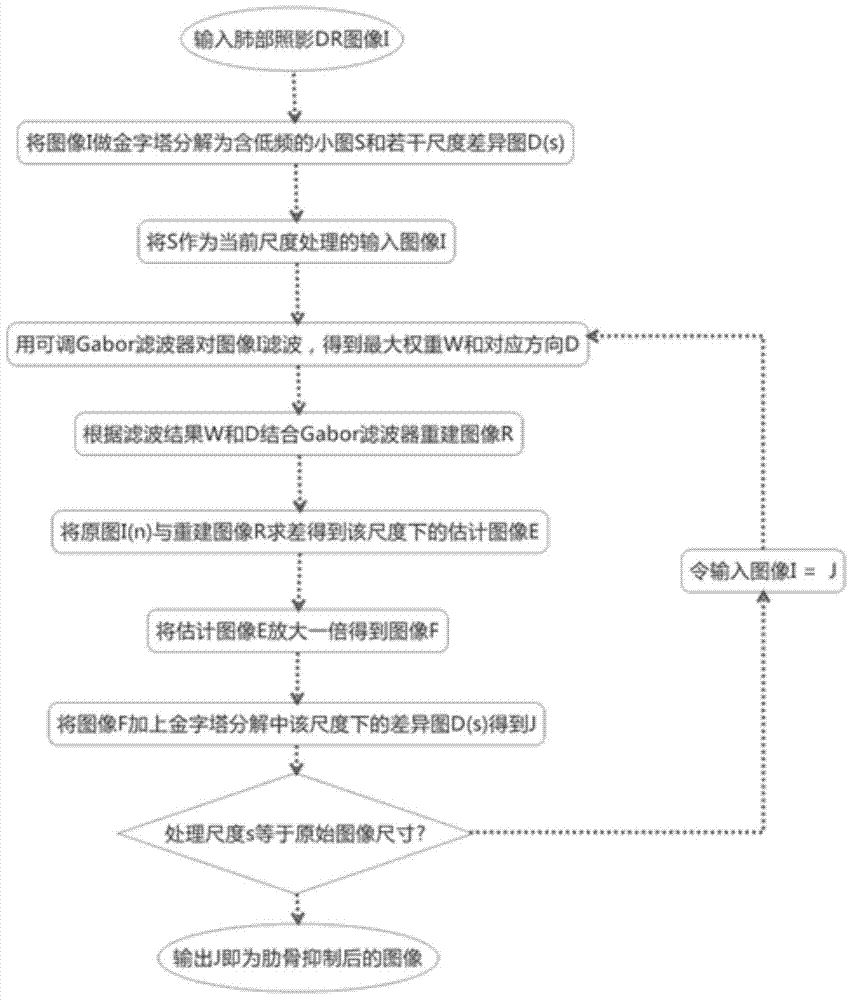

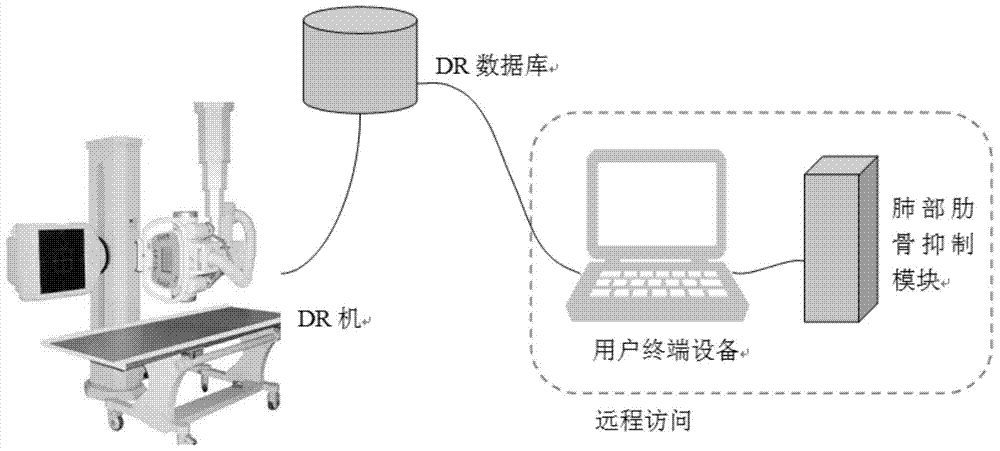

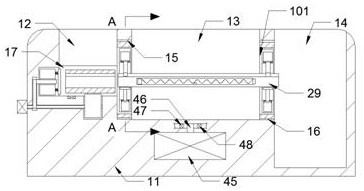

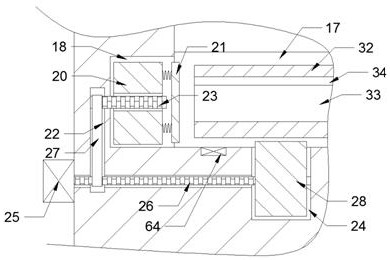

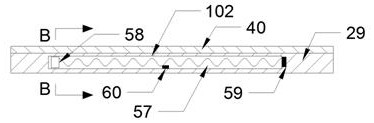

Image processing method for chest X-ray DR (digital radiography) image rib inhibition

ActiveCN105125228AIncrease visual salienceFully automatic processing2D-image generationRadiation diagnosticsImaging processingDecomposition

The invention discloses an image processing method for chest X-ray DR (digital radiography) image rib inhibition. The method comprises the following steps: acquiring a chest X-ray DR image; performing pyramid decomposition on the DR image, performing a down sampling process to obtain a Gaussian image pyramid S, and performing an up sampling process to obtain a Laplacian image pyramid difference chart D(S); taking the minimum S as a current to-be-processed image I; performing filtering processing on the image I by using an adjustable Gabor filter bank so as to obtain a reconstructed image R; differencing the to-be-processed image I and the reconstructed image R to obtain a processing result image E with weakened segment-shaped textures under the scale; and doubling the processing result image E, adding the processing result image E and a corresponding Laplacian image pyramid difference chart D(S) under the size together, and repeating the processing procedure until the size is the same as that of an original DR image, thereby obtaining an image after rib inhibition. According to the method disclosed by the invention, the visual saliency of pulmonary shadows is improved, the workload of doctors is reduced, automatic processing can be realized, and an analysis conclusion is more objective and stable.

Owner:SICHUAN UNIV

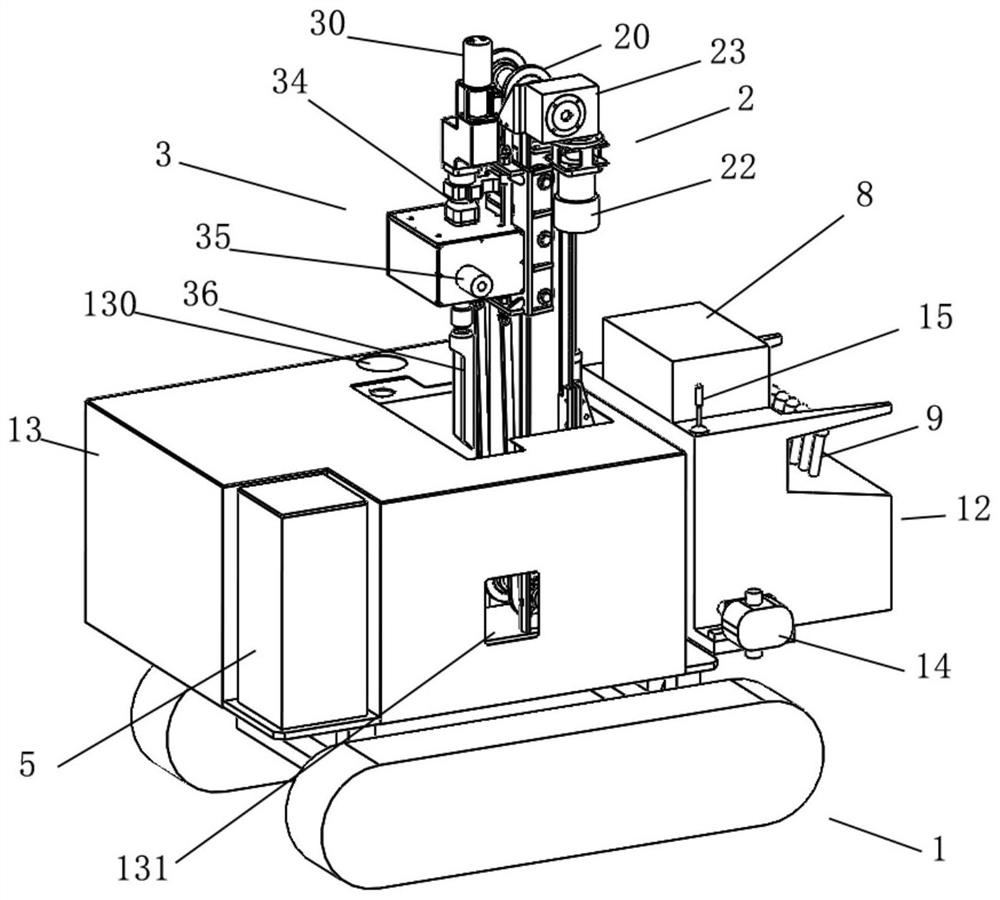

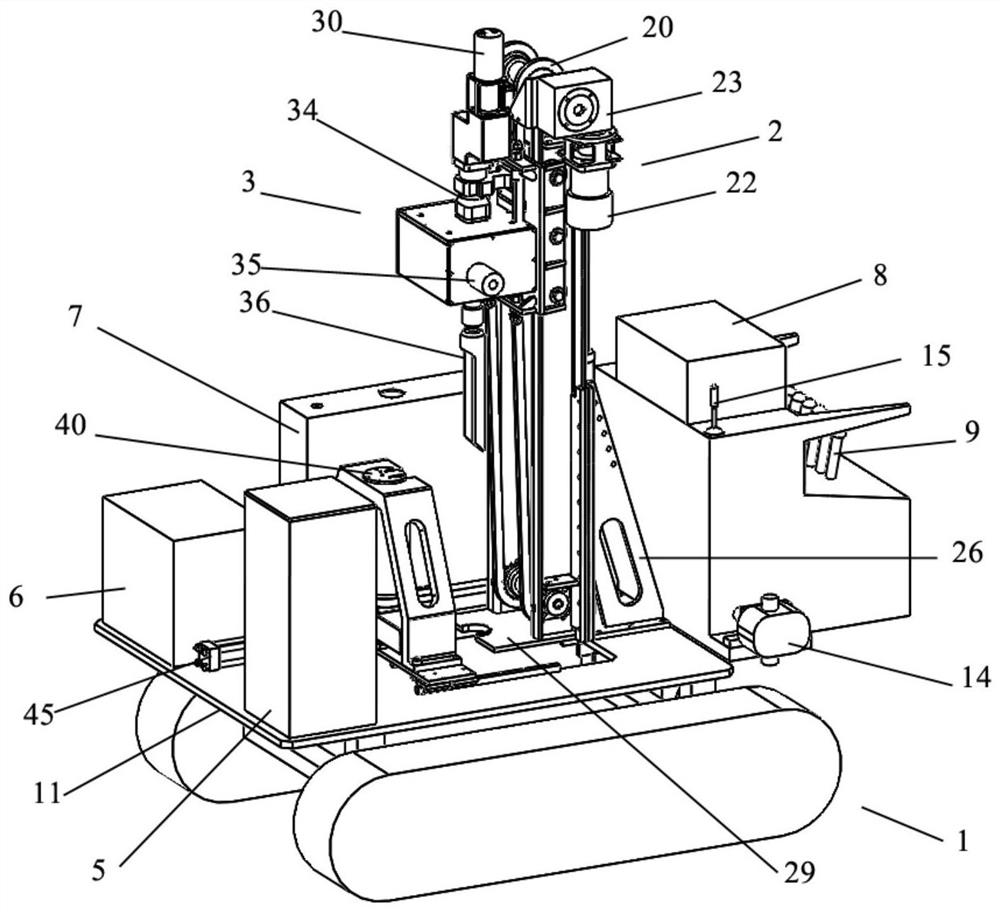

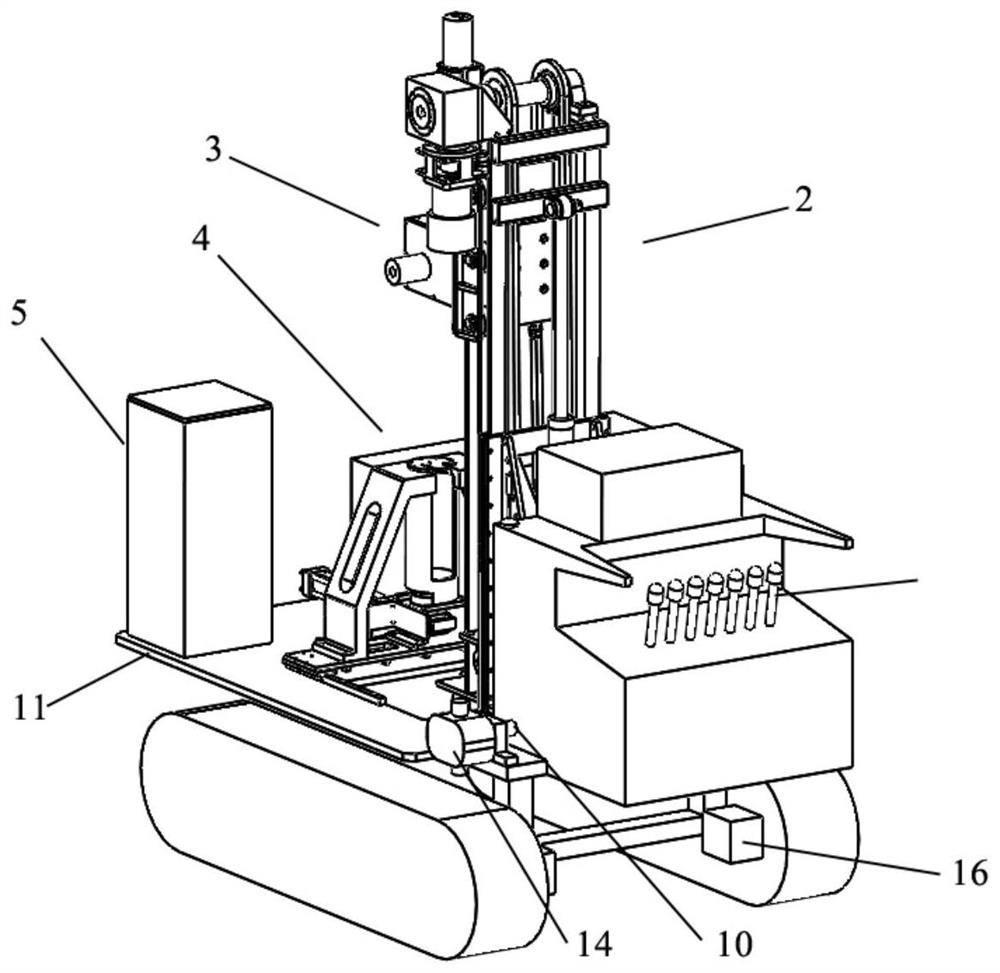

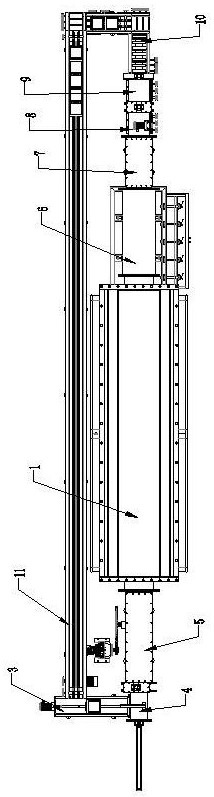

Hydraulic hammering type full-automatic soil sampling device and control method thereof

ActiveCN112146924AFully automatic processingAvoid diversityWithdrawing sample devicesSoil scienceEngineering

The invention relates to a hydraulic hammering type full-automatic soil sampling device and a control method thereof. Compared with the prior art, the defect that the analysis test result is influenced by large soil sample disturbance caused by manual soil sampling is overcome. A notch is formed in the upper bottom edge of a fixing frame, a soil scraping piece is installed on the upper bottom edgeof the fixing frame and located at the notch, the soil scraping piece is located over a flow guide cylinder, the soil scraping piece is oval, the size and the shape of the soil scraping piece are thesame as those of the inner wall of a soil sampling cylinder, a sliding groove is formed in the side portion of the flow guide cylinder, the size and the shape of the sliding groove are the same as those of the soil sampling cylinder, and when a double-acting hydraulic cylinder controls the fixing frame to move to the farthest end, the soil scraping piece is tangent to the longitudinal movement track of the inner wall of the soil sampling cylinder. Full-automatic processing of soil sampling can be achieved, the diversity of manual operation and soil disturbance are avoided, and the device canbe suitable for large-area and high-workload field soil component monitoring and collecting.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

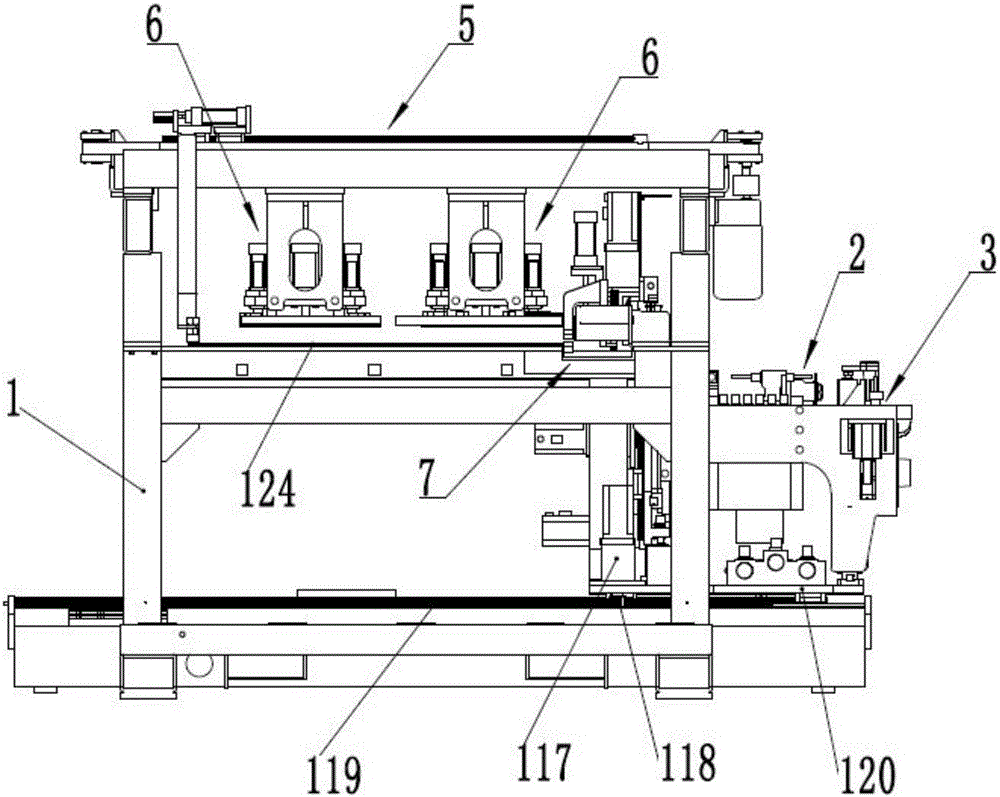

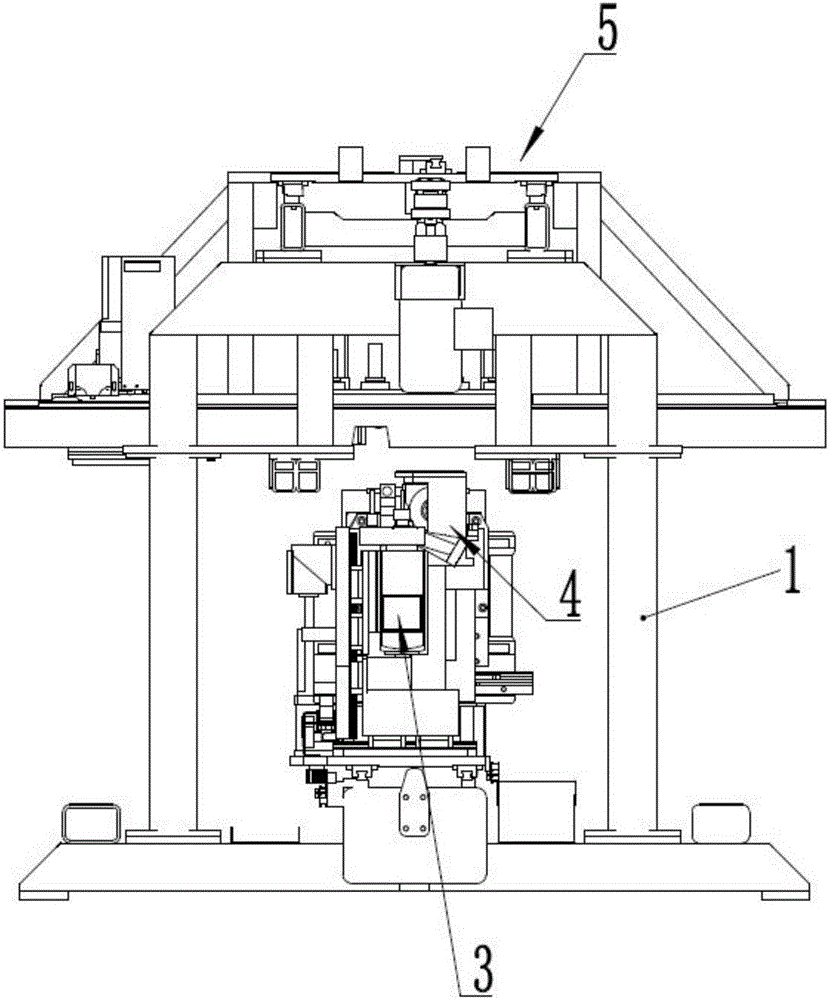

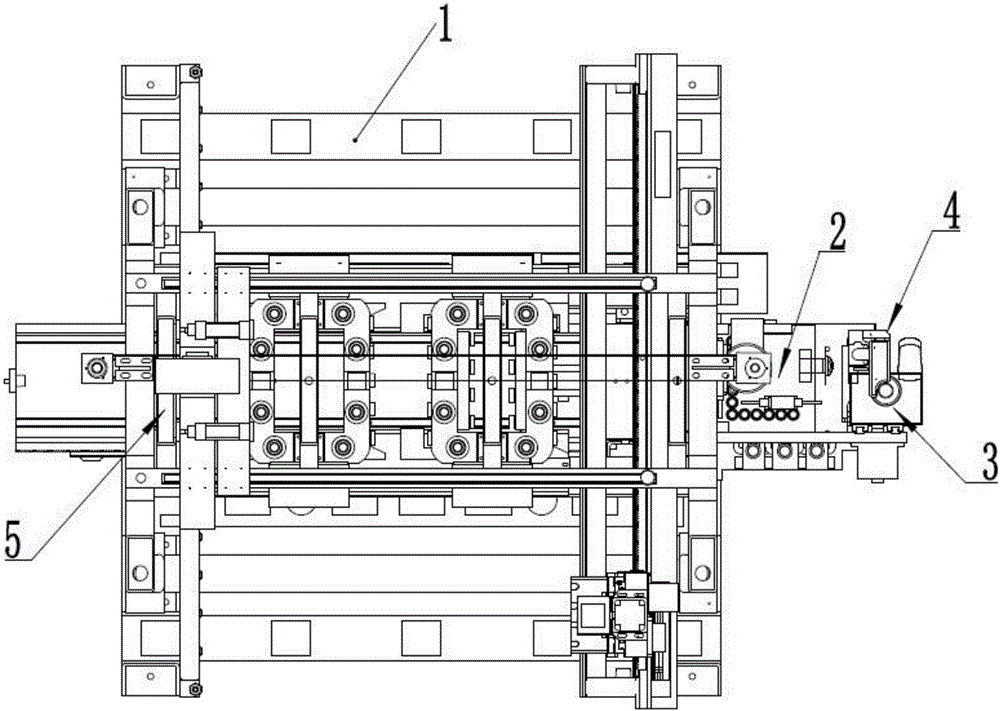

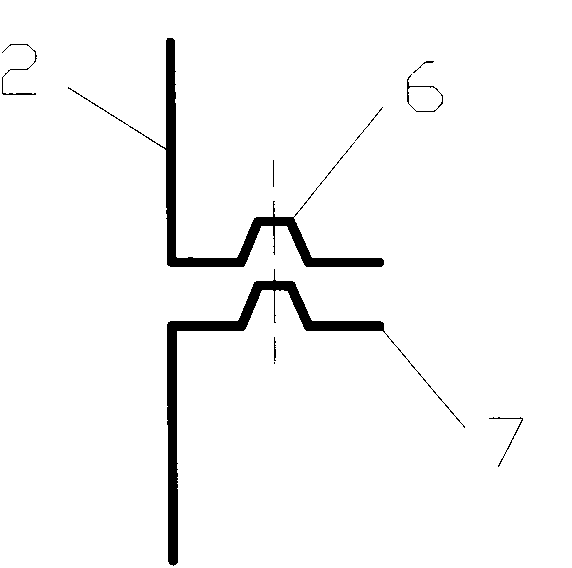

Novel numerical control drilling machine

ActiveCN105772779AReduce distortionReduce vibrationFeeding apparatusMetal working apparatusNumerical controlMilling cutter

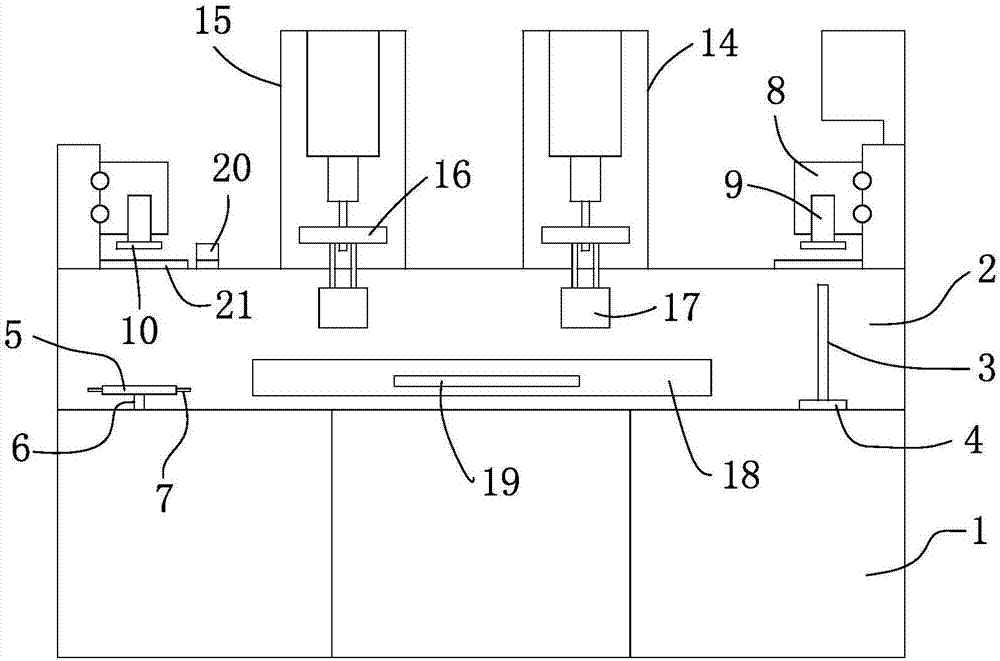

The invention discloses a novel numerical control drilling machine. The novel numerical control drilling machine comprises a rack, wherein a working table is arranged on the rack. The novel numerical control drilling machine further comprises a drilling box, a milling cutter component, an auxiliary supporting device, a push-and-block device which is used for pushing a workpiece and clamping the workpiece, a compression device used for compressing the workpiece, a material feeding clamping claw device used for clamping and moving the workpiece, an X-axis driving device used for driving the material feeding clamping claw device to move along the X-axis, a Y-axis driving device used for driving the milling cutter component, the auxiliary supporting device and the drilling box to move along the Y-axis, an A-axis driving device used for driving the milling cutter component, the auxiliary supporting device and the drilling box to move along the A-axis and a Z-axis driving device used for driving the milling cutter component and the drilling box to move along the Z-axis. The novel numerical control drilling machine is easy to operate; no technical worker is needed for operation; an ordinary worker can work through simple training, so that labor cost can be greatly reduced, and enterprise performance is improved; and workpieces of multiple specifications can be rapidly and continuously machined, and the production efficiency is high.

Owner:GUANGDONG SANDAR CNC MACHINERY CO LTD

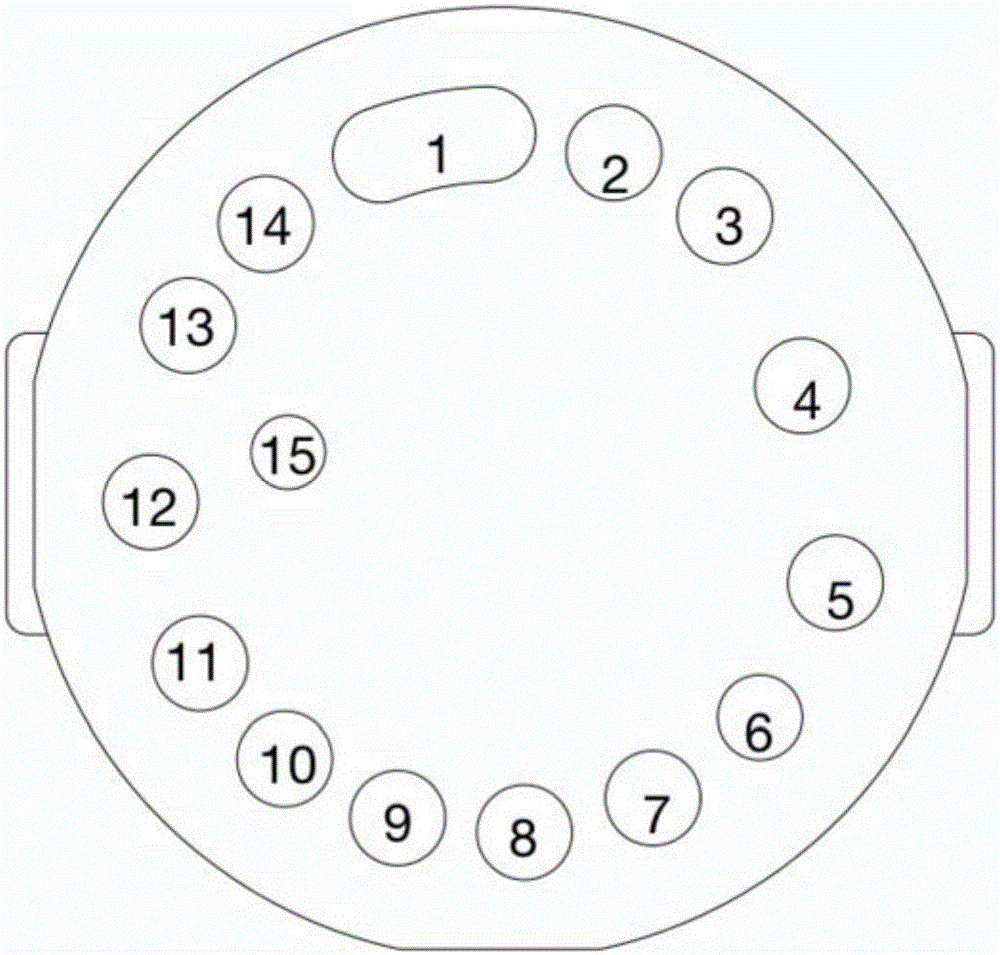

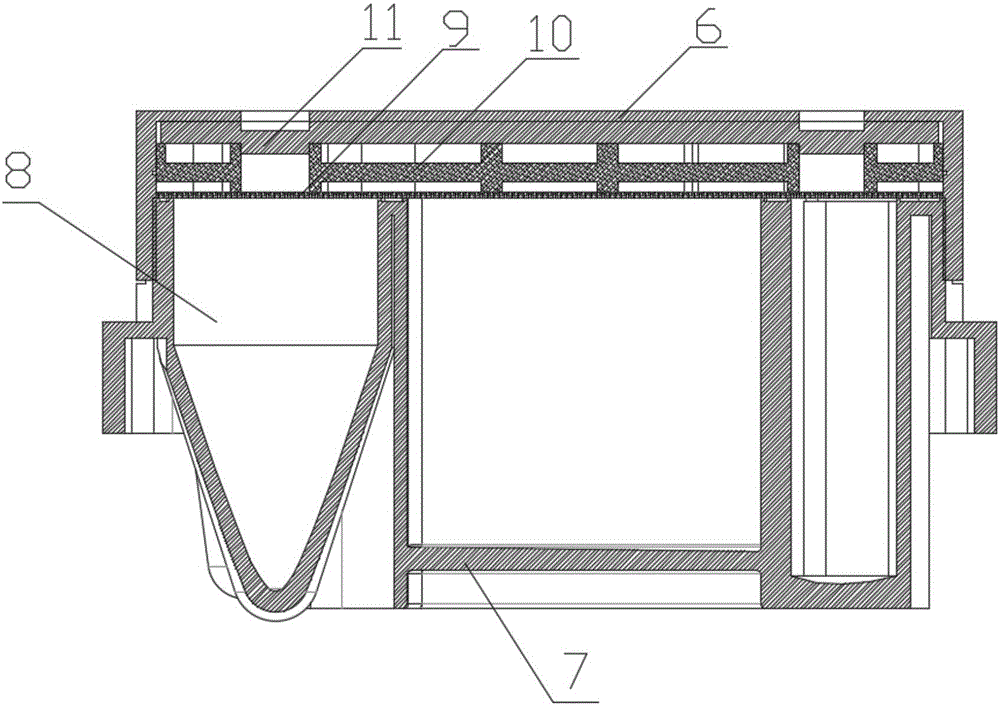

Reagent plate for automatic pretreatment of nucleic acid detection

InactiveCN106399055ASimplify the testing processAvoid cumbersomeBioreactor/fermenter combinationsBiological substance pretreatmentsChemistryNucleic acid sequencing

The invention discloses a reagent plate for automatic pretreatment of nucleic acid detection. The reagent plate is characterized by comprising a cover plate and a reagent tray, wherein a plurality of reagent holes are formed in the reagent tray; nucleic acid sequencing pretreatment reagents are contained in the reagent holes; aluminum foil sealing films are arranged at the opening of the reagent holes. The reagent plate for automatic pretreatment of nucleic acid detection, provided by the invention, in combination with an automatic pretreatment device for nucleic acid detection, can realize the full automatic pretreatment of the nucleic acid detection, including extraction, library construction and product purification; the final products can be directly applied to high-throughput sequencing; the whole process is unmanned.

Owner:HANGZHOU GENE META MEDICAL DEVICE CO LTD

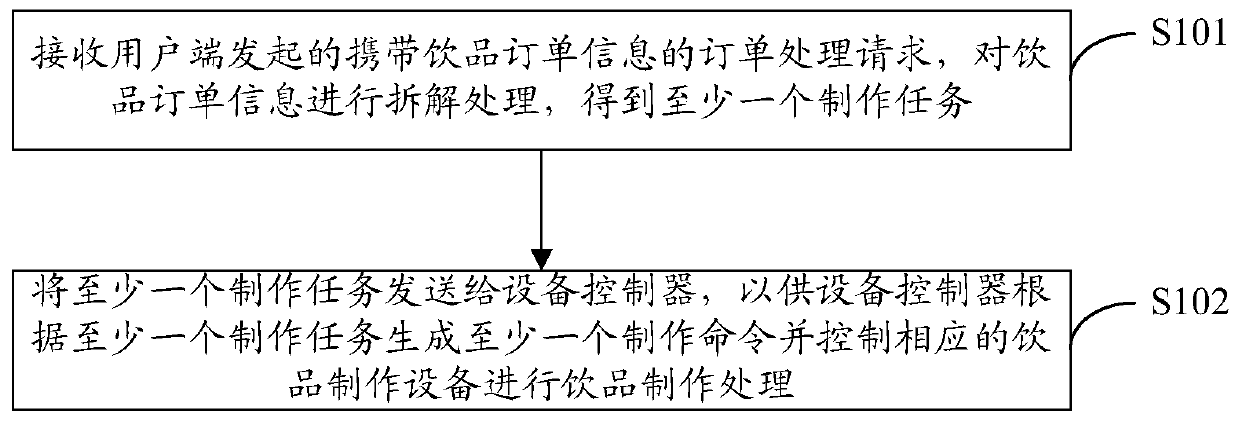

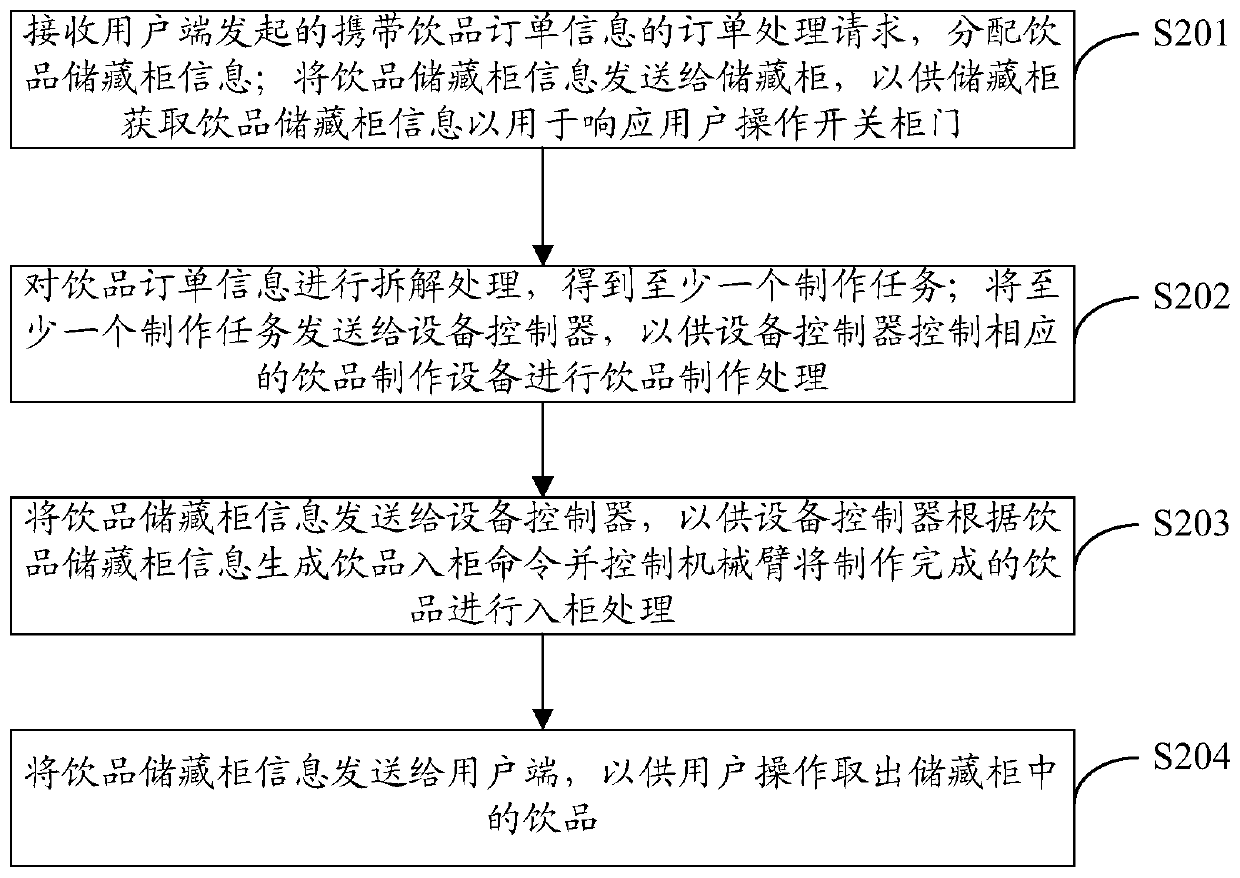

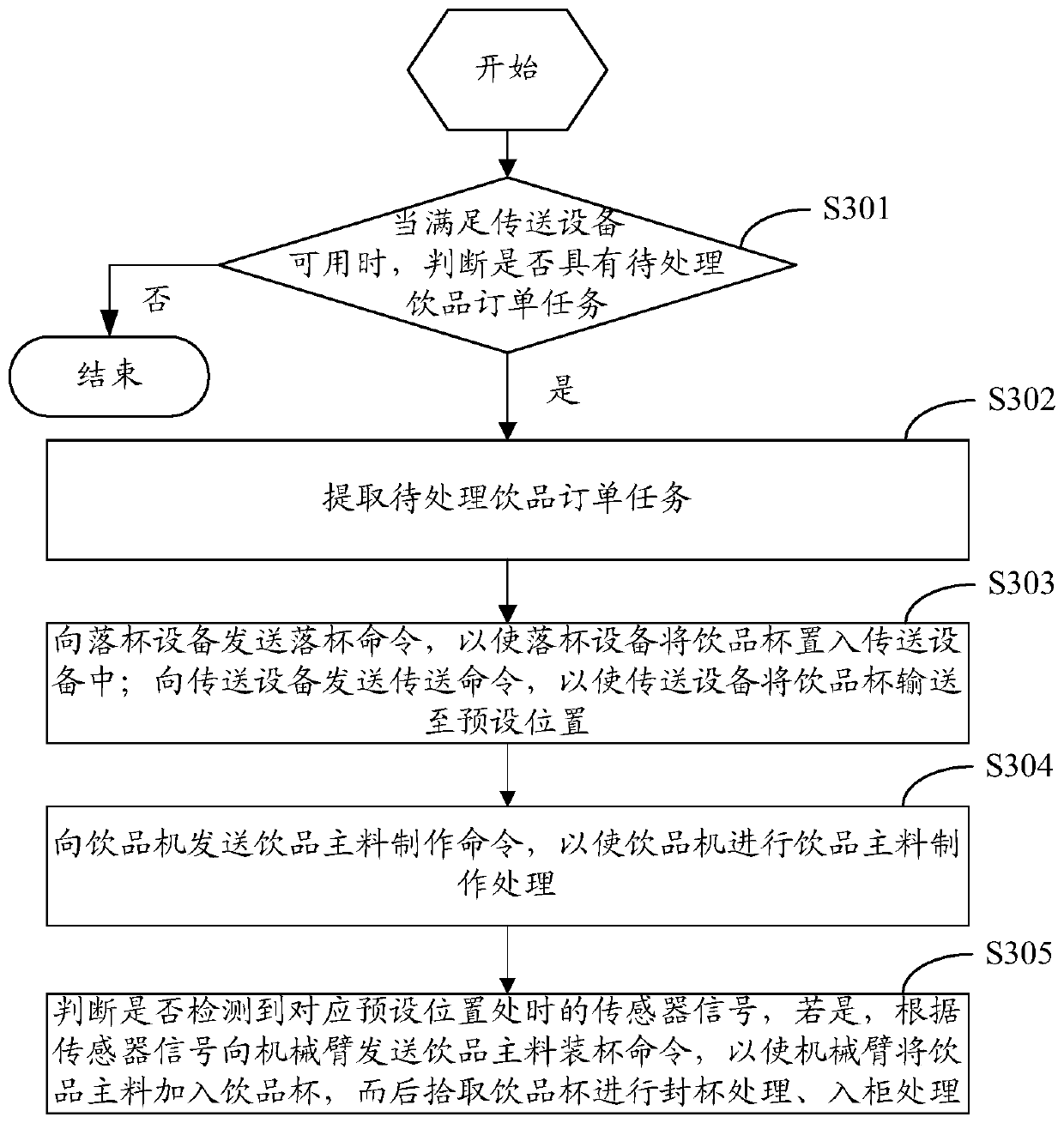

Beverage order processing method realized based on IoT equipment and order controller

InactiveCN110298729AImprove stabilityFully automatic processingBuying/selling/leasing transactionsApparatus for dispensing fluids/granular materialsOrder controlOrder processing

The invention discloses a beverage order processing method based on IoT equipment and an order controller, and the method comprises the steps: receiving an order processing request which is initiatedby a user side and carries beverage order information, carrying out the disassembly of the beverage order information, and obtaining at least one manufacturing task; and sending the at least one making task to an equipment controller, so that the equipment controller generates at least one making command according to the at least one making task and controls corresponding beverage making equipmentto carry out beverage making processing. According to the scheme of the invention, the order related data can be transmitted between the IoT equipment, so that the equipment controller generates themaking command according to the received making task so as to control the making equipment to make beverages, manual or other intelligent machines are not needed to operate the making equipment, and full-automatic processing from order receiving to beverage making completion is realized.

Owner:KOUBEI SHANGHAI INFORMATION TECH CO LTD

Full-automatic treatment apparatus for chlorine gas in calcium hypochlorite production

ActiveCN109865408AEfficient and comprehensive absorption treatmentEasy to cleanCombination devicesDispersed particle filtrationFiltrationEngineering

The invention discloses a full-automatic treatment apparatus for chlorine gas in calcium hypochlorite production. The apparatus comprises an absorption pool, a first dust removal chamber and a seconddust removal chamber, wherein the side wall of the absorption pool is fixedly connected with the second dust removal chamber, a gas intake pipe communicates with the side wall of the first dust removal chamber, and the first dust removal chamber and the second dust removal chamber are connected through a square through hole. Through the combination of the absorption pool, the first dust removal chamber and the second dust removal chamber, the residual chlorine gas in the calcium hypochlorite production can be efficiently and comprehensively absorbed and treated. The dripping liquid is collected by a collecting box, a rotary disc is driven to rotate back and forth under the action of third springs, and a pipe sleeve is pushed to jack a soft branch pipe to intermittently impact a first arc-shaped plate, and a spraying effect is formed due to impacts of the soft branch pipe and a hard branch pipe, so that the drifting chlorine gas can be effectively absorbed. The combination of a first filtration net and a second filtration net can further enhance the effect of chlorine gas purification, and ensure that the exhausted gas does not pollute the environment.

Owner:宁夏富来化工产品有限公司

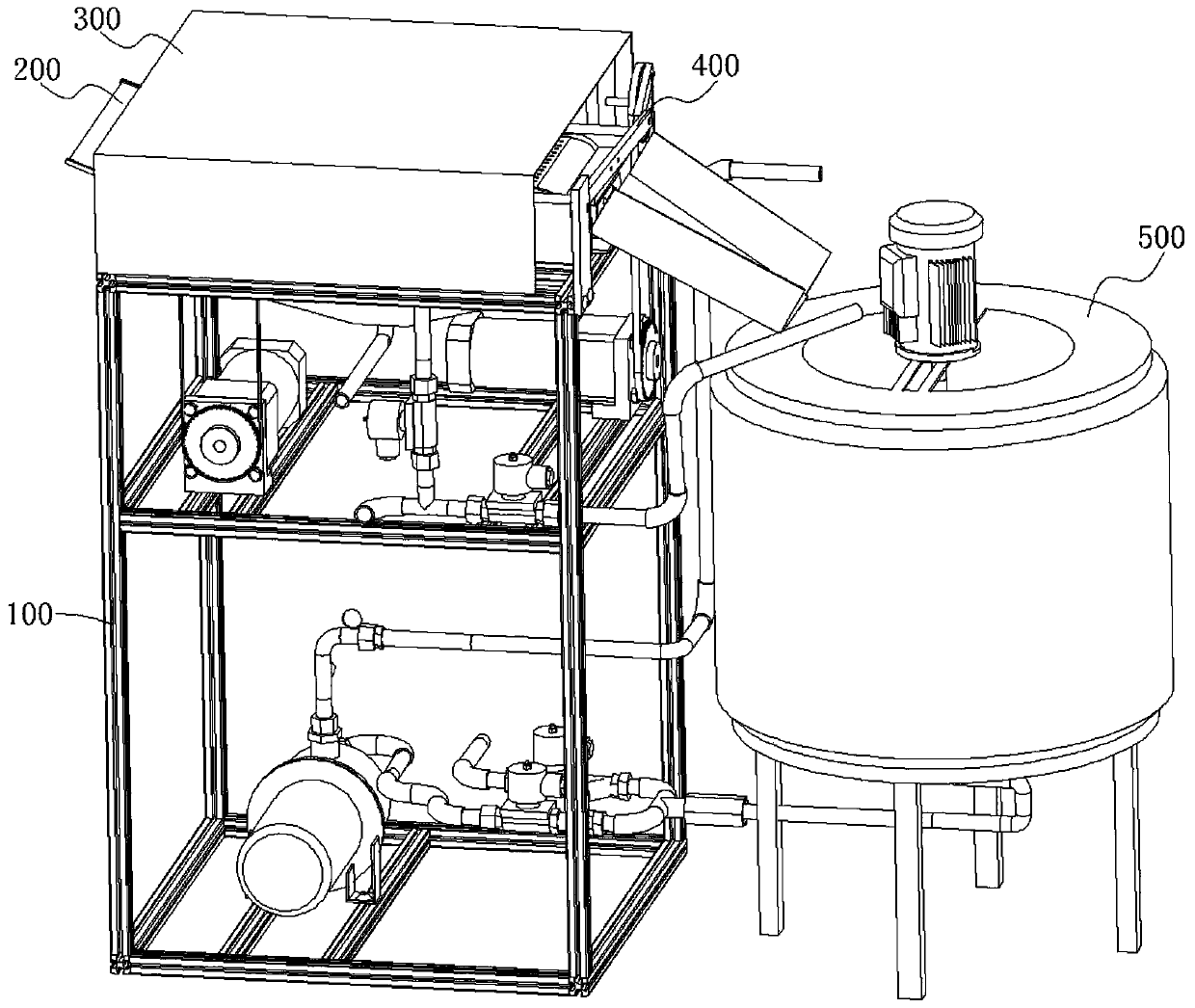

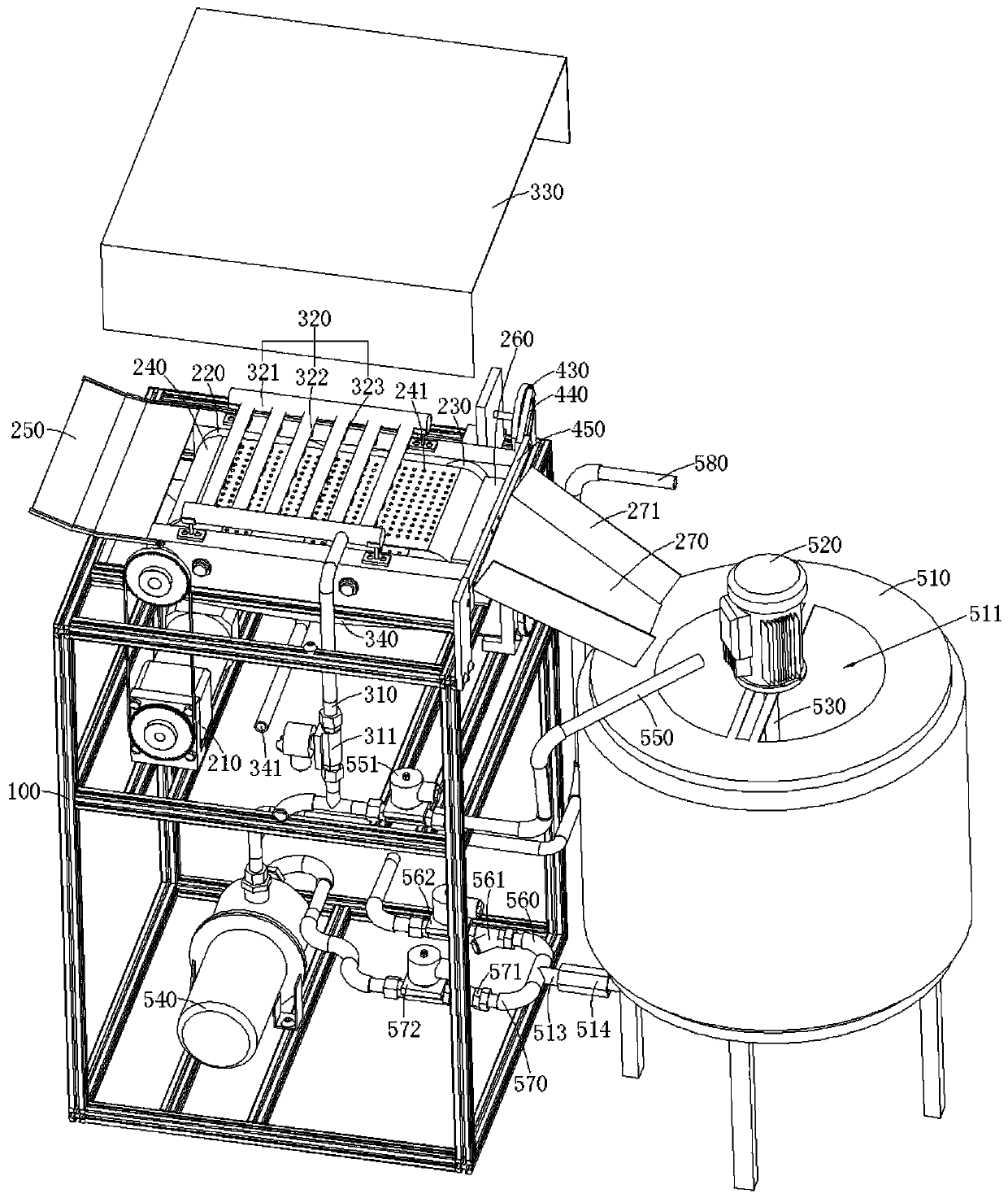

High-precision grinding device for inner diameter of metal pipe

PendingCN111975488AFully automatic processingRevolution surface grinding machinesGrinding drivesDrive shaftElectric machinery

The invention discloses a high-precision grinding device for the inner diameter of a metal pipe. The high-precision grinding device comprises a feeding mechanism, a compressing mechanism, a grinding mechanism, a dust collecting mechanism and a discharging mechanism; the compressing mechanism comprises a main rack and a plurality of downward-pressing rollers arranged on the main rack; a plurality of rotating roller shafts are arranged on the main rack, and the rotating roller shafts are driven by a first motor and a first belt; a grinding rack is arranged on one side of the main rack, and a feeding belt driven by a belt pulley is arranged on the grinding rack; a grinding seat is fixedly arranged on the feeding belt, and a plurality of grinding motors and a transmission shaft driven by the grinding motors are arranged on the grinding seat; a grinding head is arranged at the tail end of the transmission shaft, and the grinding head is used for grinding the inner diameter of the pipe; andthe dust collecting mechanism is arranged on the side, away from the grinding rack, of the main rack and used for treating chippings generated by grinding. Fully-automatic treatment of feeding, conveying, grinding and discharging can be achieved, a plurality of pipes can be simultaneously ground, and the chippings can be automatically cleared.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

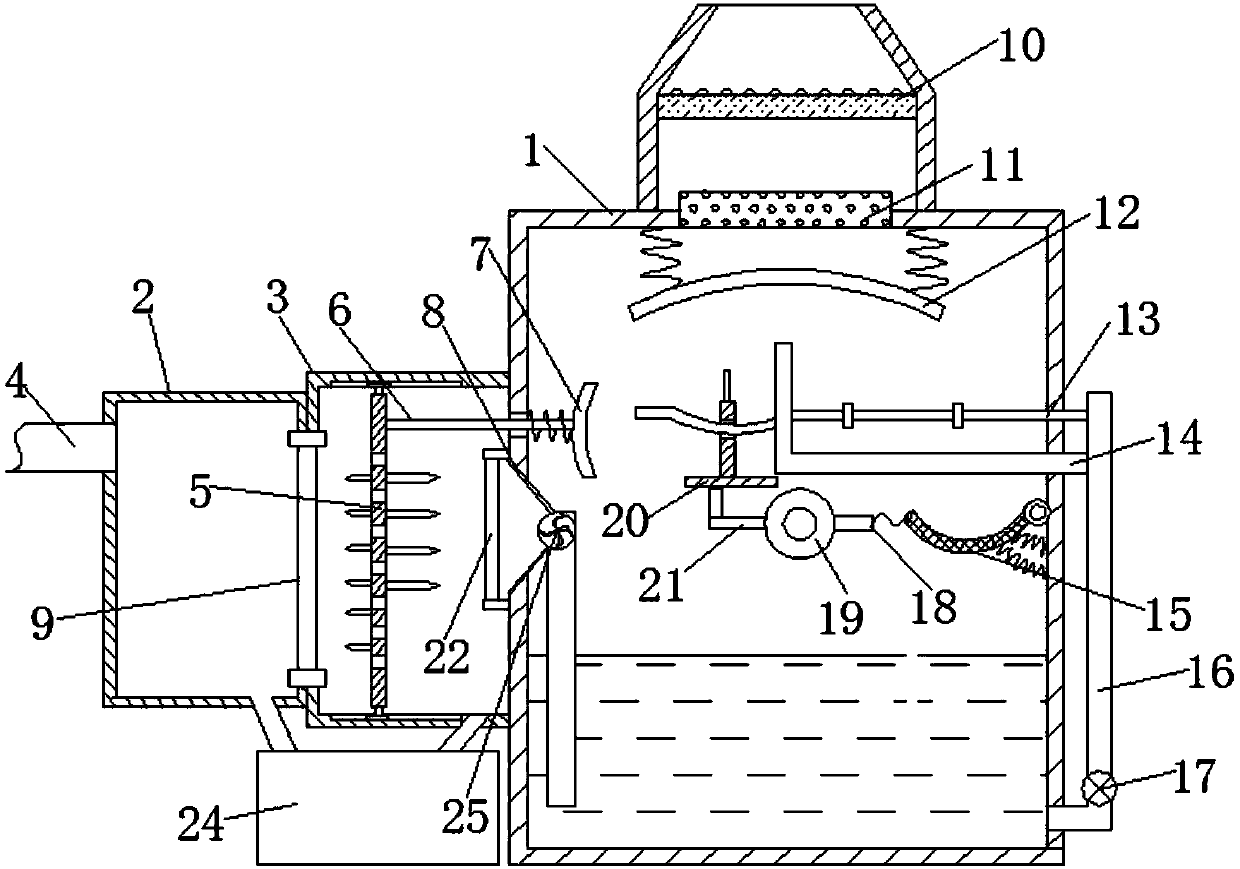

Dendrobium officinale cooking machine

ActiveCN110433251AFully automatic processingPharmaceutical product form changeDomestic articlesEngineeringMechanical engineering

The present invention relates to a dendrobium officinale cooking machine. The dendrobium officinale cooking machine of the invention comprises: a conveying device, which is used for transporting dendrobium officinale; a cleaning device, which is disposed on the top of the conveying device and is used for cleaning the dendrobium officinale during transportation; a cutting device, which is disposedat a discharge end of the conveying device and is used for cutting the cleaned dendrobium officinale; and a cooking device, which is disposed at a discharge end of the conveying device and is used forcooking the cut dendrobium officinale. The dendrobium officinale cooking machine can automatically process fresh dendrobium officinale, that is, the cleaning, segmenting, crushing, and cooking of thefresh dendrobium officinale can be completed automatically.

Owner:SOUTH CHINA AGRI UNIV

Bagged garbage treatment mechanism and treatment device

PendingCN112793876AGuaranteed stable positionReduce processing costsRefuse receptaclesUnpacking by cuttingSimulationBin bag

Owner:TSINGHUA UNIV

Full-automatic sample pretreatment device and treatment method

PendingCN113189255AFully automatic processingReduce manual labor intensityComponent separationSolid phase extractionMechanical engineering

A full-automatic sample pretreatment device comprises a mounting frame, a gun head box module, a reagent disc module, a sample disc module and a collecting module which are arranged on the lower portion of the inner cavity of the mounting frame, an extraction module is fixedly arranged in the inner cavity of the mounting frame and located above the collecting module, and a sampling and treatment module is located in the inner cavity of the mounting frame and acts in the X-axis direction, the Y-axis direction and the Z-axis direction. The sampling and processing module comprises a sampling mechanism and a positive pressure inflating device, the sample injection module is located in the inner cavity of the mounting frame and acts in the X-axis direction and the Y-axis direction, and a needle tail sample injection valve of a sample injection needle of the sample injection module is used for being connected with an infusion pump of the chromatographic instrument. According to the invention, through mutual cooperation of the modules and combination of off-line solid-phase extraction and on-line solid-phase extraction, full-process automatic operation from sample introduction to result output of a complex sample is realized, the working efficiency is high, and the error is small.

Owner:苏州艾迪迈医疗科技有限公司

Continuous sealed high-temperature mesh belt furnace

The invention discloses a continuous sealed high-temperature mesh belt furnace. The continuous sealed high-temperature mesh belt furnace comprises a furnace body and a rack, the continuous sealed high-temperature mesh belt furnace further comprises a feeding propulsion mechanism, a double-door front discharging replacement chamber, a sealed mesh belt driving chamber arranged at the front end of the furnace body, and the continuous sealed high-temperature mesh belt furnace further comprises a furnace body water cooling section, a sealed mesh belt rotating chamber, a sealed discharging driving roller set, a double-door rear discharging replacement chamber, a material moving mechanism and a material circulating conveying mechanism arranged at the rear end of the furnace body. According to themesh belt furnace, all the parts are connected in a sealed mode, especially the parts connected with the front portion and the rear portion of the furnace body in a sealed mode, sealing of the mesh belt furnace is achieved, and compared with an open-type mesh belt furnace, the gas consumption can be reduced, and the atmosphere using cost is saved.

Owner:湖南汉冶科技有限公司

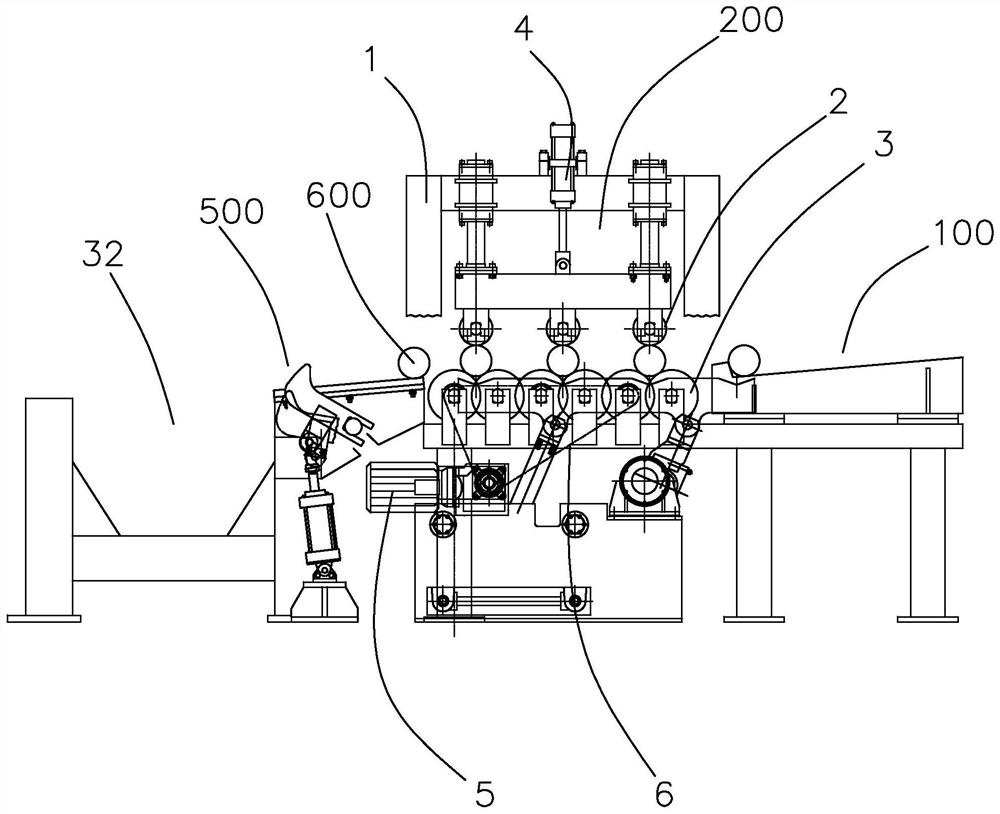

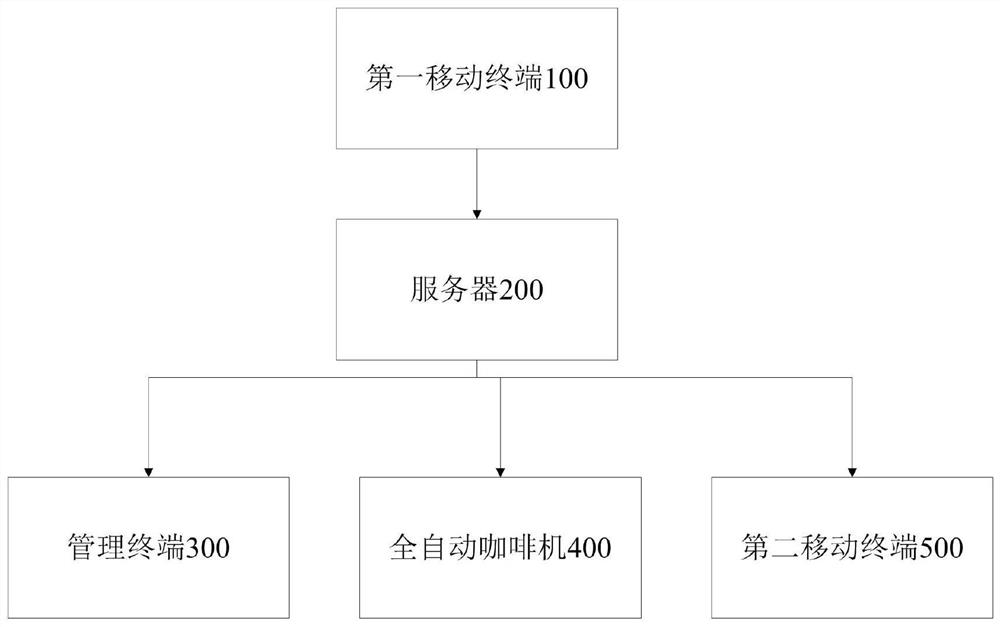

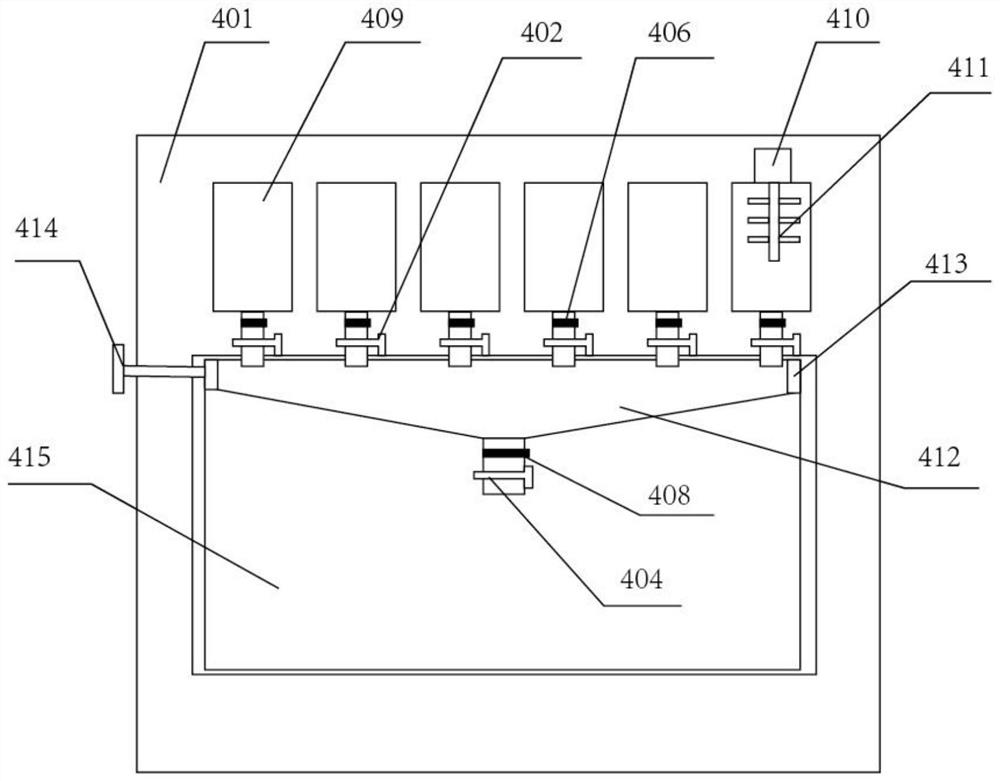

Full-automatic coffee machine system based on Internet of Things

PendingCN113012349AFully automatic processingBeverage vesselsApparatus for dispensing fluids/granular materialsThe InternetAutomatic processing

The invention discloses a full-automatic coffee machine system based on the Internet of Things, which comprises a full-automatic coffee machine, a management terminal, a first mobile terminal, a second mobile terminal and a server, and the first mobile terminal, the second mobile terminal, the full-automatic coffee machine and the management terminal are in wireless network connection with the server; the server sends an order request to the full-automatic coffee machine, the second mobile terminal and the management terminal based on an order placing request of the first mobile terminal, the full-automatic coffee machine automatically makes coffee based on the order request, and the management terminal performs order printing and order management based on the order request. And the second mobile terminal carries out delivery based on the order request. According to the invention, full-automatic processing from customer ordering, coffee making and coffee delivery is realized, and customization can be carried out according to the taste of a user.

Owner:广州市钛菱云科技有限公司

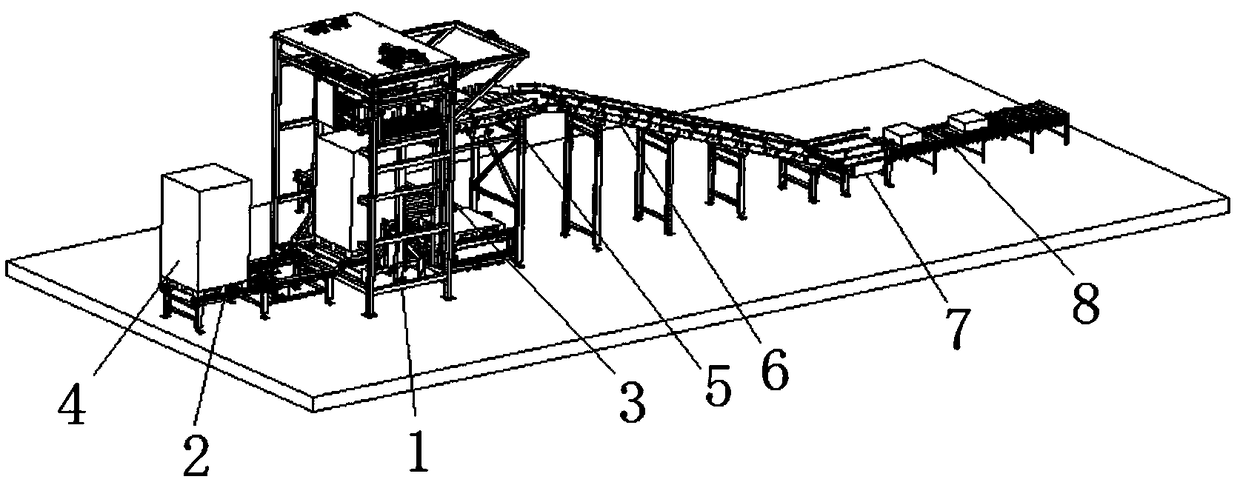

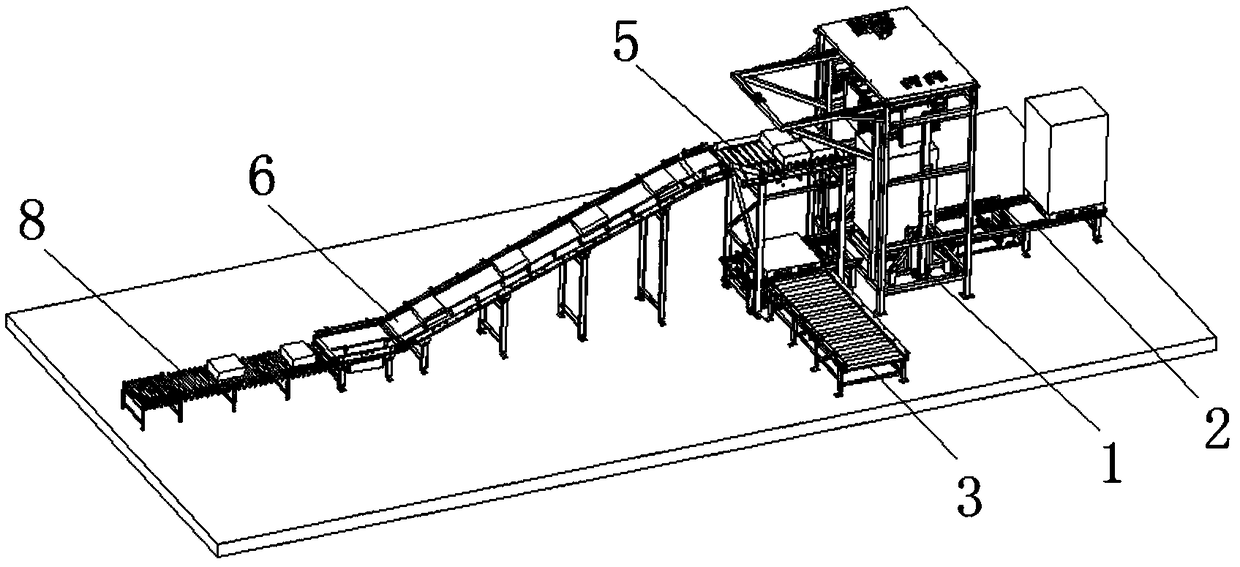

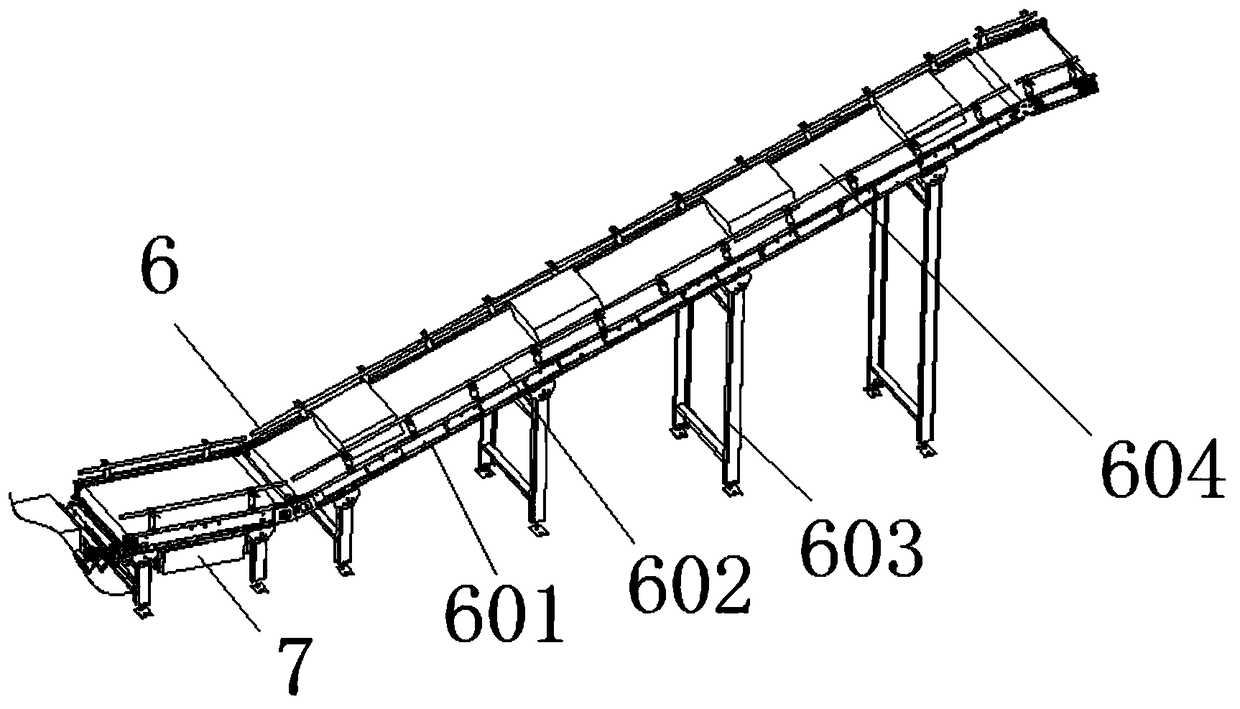

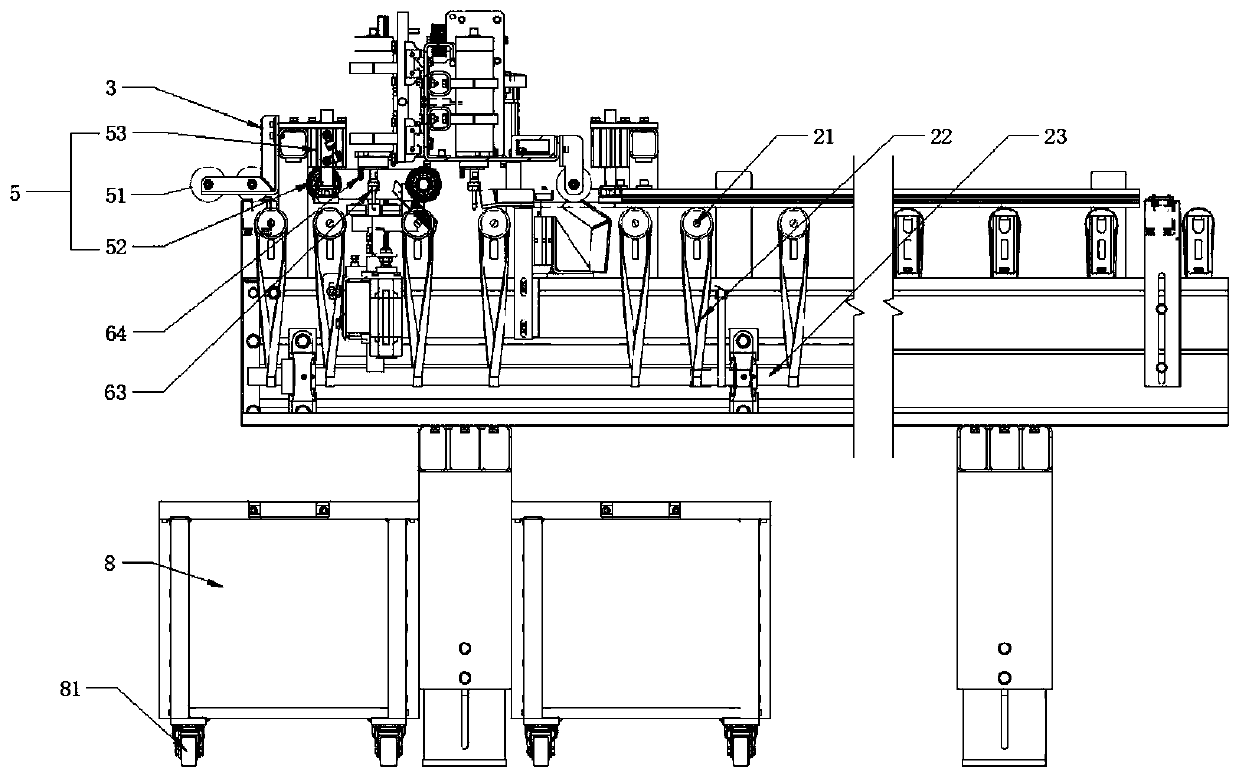

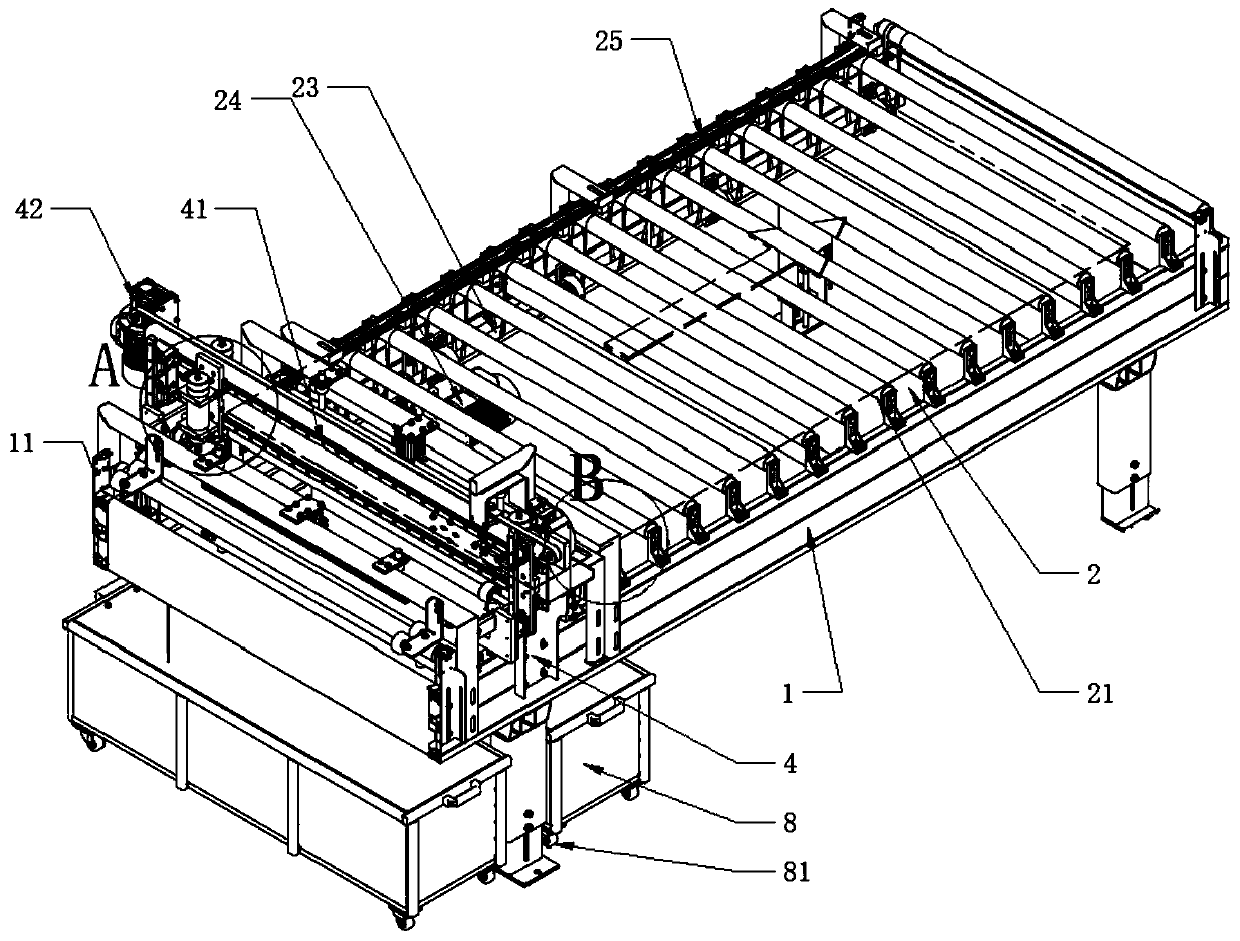

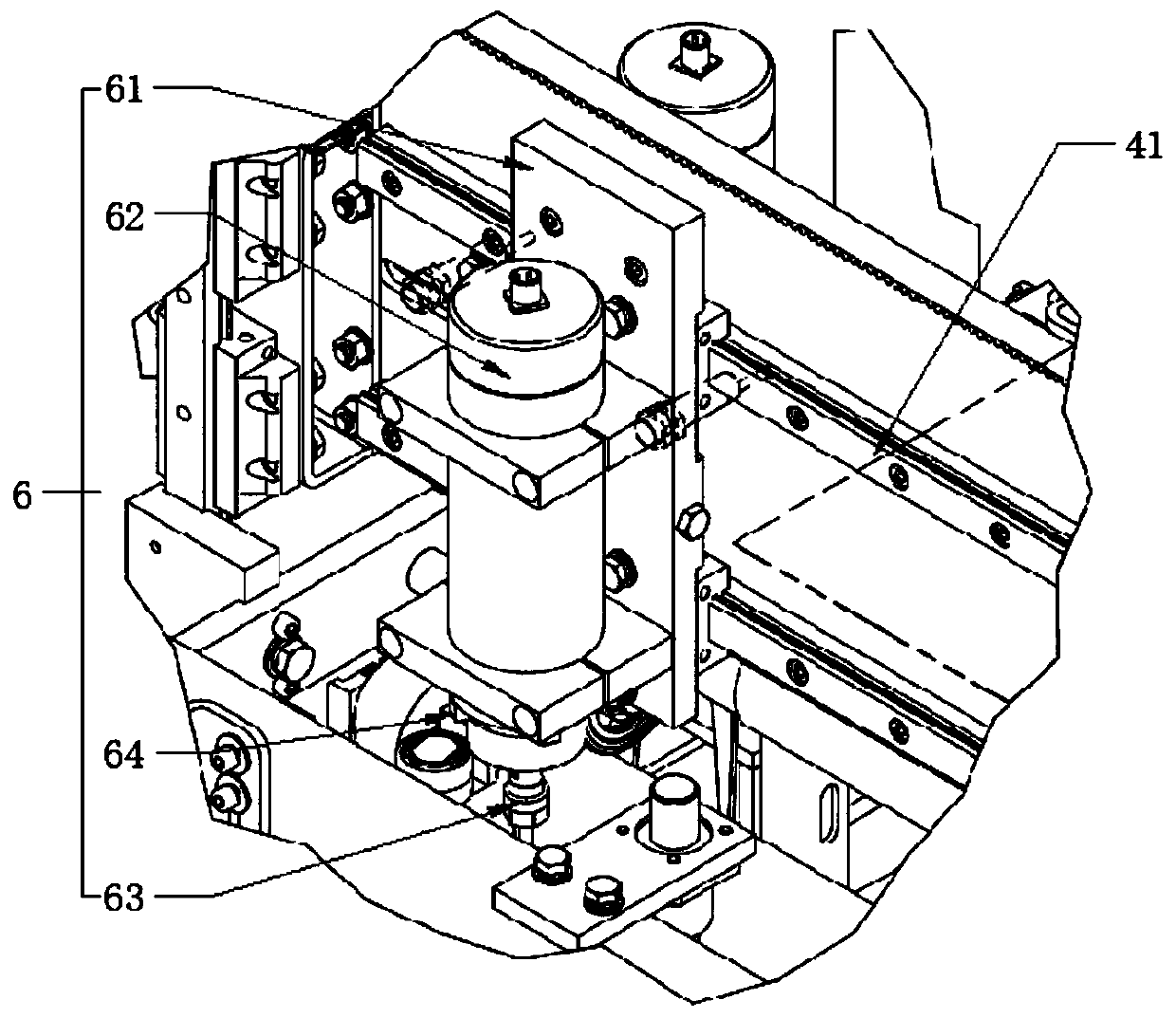

Automatic unstacking system

PendingCN109319512AImprove practicalityFully automatic processingStacking articlesDe-stacking articlesPulp and paper industryAutomatic testing

The invention discloses an automatic unstacking system comprising a vacuum suction cup whole layer unstacking machine and a differential cargo scattering roller conveyor. A tray conveyor is installedon the left side of the lower portion of the vacuum suction cup whole layer unstacking machine, an empty tray recycling conveyor is arranged on the right side of the lower portion of the vacuum suction cup whole layer unstacking machine, the differential cargo scattering roller conveyor is installed on the upper right portion of the vacuum suction cup whole layer unstacking machine, a downhill belt conveyor is arranged on the right side of the differential cargo scattering roller conveyor, a driving mechanism is installed on the lower right portion of the downhill belt conveyor, and a telescopic conveyor is arranged on the right side of the downhill belt conveyor. The automatic unstacking system is provided with the downhill belt conveyor and the telescopic conveyor, the downhill belt conveyor and the telescopic conveyor cooperate with a telescopic bracket and telescopic legs to be used, and the height and the inclined angle of the downhill belt conveyor and the telescopic conveyor areeffectively adjusted.

Owner:TAIYUAN FORTUCKY LOGISTICS EQUIP TECH CO LTD

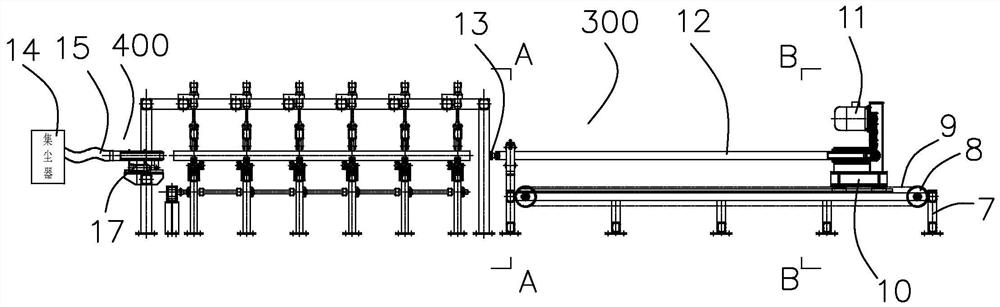

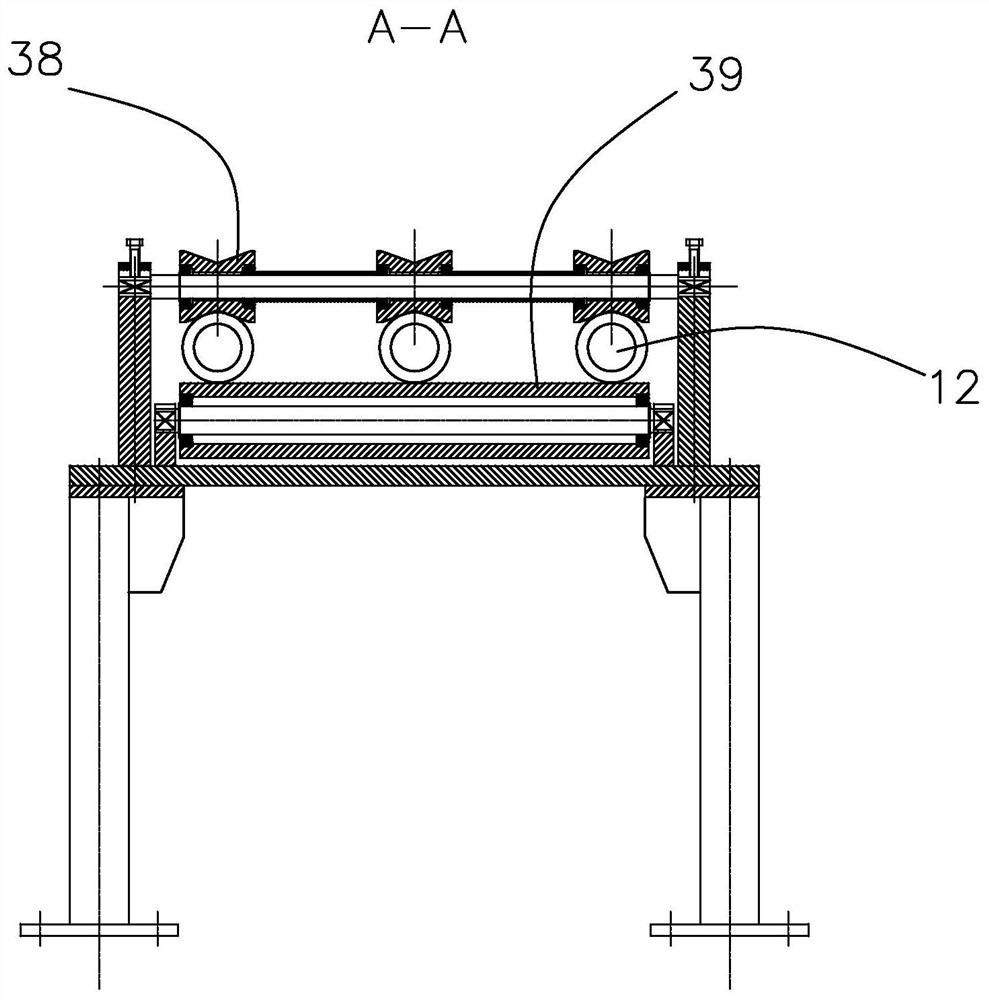

Automatic trimming system for wood veneers

PendingCN111376357AFully automatic processingImprove product qualityOther plywood/veneer working apparatusMulti-purpose machinesWood veneerProcess engineering

The invention discloses an automatic trimming system for wood veneers, and belongs to the technical field of woodworking equipment. By virtue of feeding assisting assemblies, trimming assemblies and awaste recovery assembly which are arranged on a machine frame, the automatic trimming system for the wood veneers has the advantages of realizing full-automatic processing of wood feeding, trimming and veneer recovery, replacing manual trimming in the prior art, greatly improving the trimming efficiency and trimming precision of the veneers with overhanging parts, and improving the product quality of woodworking.

Owner:GUANGZHOU CHENXU AUTOMATION EQUIP

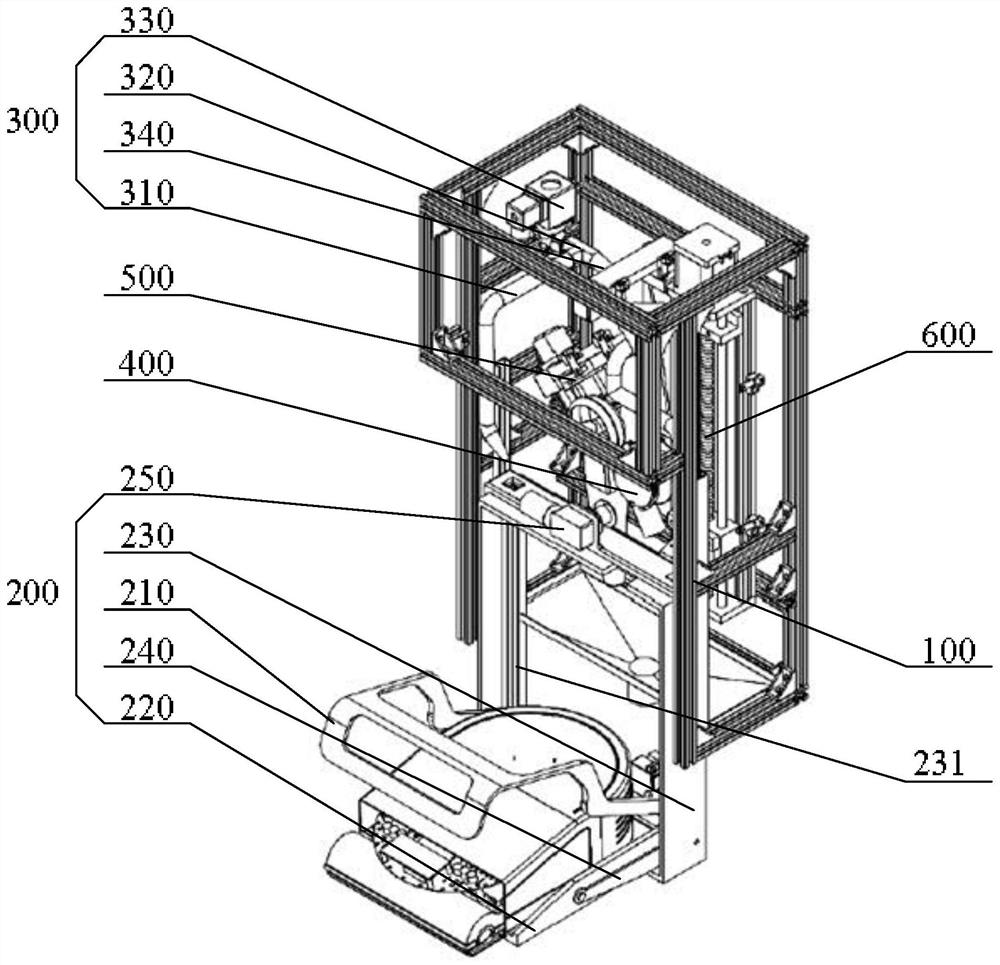

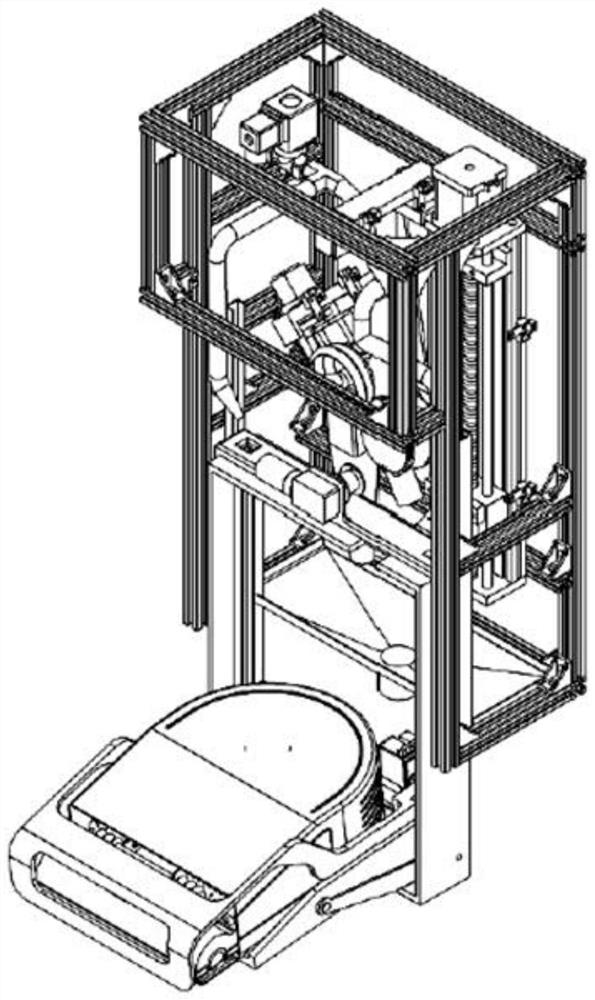

Equipment for treating garbage and supplying water and power for sweeping and mopping robot

ActiveCN113558535AFully automatic processingMitigating technical issues requiring human assistance to workCarpet cleanersFloor cleanersSewage outfallEngineering

The invention provides equipment for treating garbage and supplying water and power for a sweeping and mopping robot, and relates to the technical field of sweeping robots. The equipment comprises a frame main body, a holding assembly, a water supply assembly, an uncovering assembly and a pollution discharge assembly; through the arrangement of the holding assembly, the floor washing robot is fixed and is driven to turn into a supply area, after the floor washing robot is in place, the water supply assembly communicates with a water purification tank of the floor washing robot to supply clear water to the floor washing robot, the cover opening assembly opens a pollution discharge cover on the floor washing robot, and the pollution discharge assembly penetrates through a pollution discharge opening of the floor washing robot to flush the sewage tank in the floor washing robot so as to discharge the sewage, so that the technical effects of fully automatically treating the floor washing robot and effectively saving manpower are achieved, and the technical problem that a floor sweeping robot in the prior art needs manual assistance to work is solved.

Owner:北京笑融机器人科技有限公司

Quick manufacturing process of rotational moulding machine die

InactiveCN101920440BAchieve mechanical propertiesFast preparation processSpecial data processing applicationsNumerical controlFree form

The invention discloses a quick manufacturing process of a rotational moulding machine die. The process comprises the following steps of: obtaining a surface area; selecting a material; selecting a thickness; manufacturing lines and controlling; manufacturing a measurement pressure relief hole; manufacturing a flange edge; manufacturing a die frame; and manufacturing a locking device, wherein a numerical control sheet metal incremental forming technology is utilized as a core for manufacturing the die to realize most mechanical characteristics of the die. Compared to casting, the direct sheet mould-free forming does not need to consider the magnification ratio, a die is directly produced according to a required size of a plastic product, and the surface area is obtained through a numerical control mould-free forming device and used as an inventory reference of a rotational moulding raw material. Because most steps in the manufacturing process of the rotational moulding machine die can be finished by utilizing one numerical control mould-free forming device, the automation, the precision, the efficiency and the flexible level in the manufacturing process are greatly improved, and the cost of the manufacturing process is obviously lower than that of a traditional manufacturing process.

Owner:WUXI AOFUTE PRECISION RAPID PROTOTYPING TECH

A production equipment capable of automatically processing intersecting lines of metal pipe bodies

ActiveCN110961717BNo manual operationFully automatic processingTube shearing machinesMaintainance and safety accessoriesMachine partsStructural engineering

The invention discloses production equipment capable of automatically machining a metal pipe body intersecting line. The production equipment comprises a pedestal. The upper end of the pedestal is fixedly connected with a fixing base. A sliding chute is formed in the upper end of the pedestal. The inner wall of the sliding chute is connected with a lead screw nut in a sliding mode, and the upper end of the lead screw nut is fixedly connected with a square plate. A through hole is formed in the side wall of the square plate. A machining part is installed on the inner top of the through hole. Anarc-shaped cavity is formed in the side wall of the square plate. According to the production equipment capable of automatically machining the metal pipe body intersecting line, a conveying belt usedfor conveying metal pipe bodies is made to align a feeding chute, the metal pipe bodies can be conveyed into the feeding chute directly, first rolling wheels can rotate under the action of a drivingdevice so that the metal pipe bodies can be conveyed into a through groove, at the moment, a sensor sends out signals to drive a push rod and a clamping plate to move upwards, the metal pipe bodies can be clamped, and meanwhile the square plate can be pulled to get close to metal pipes so that cutting machining can be performed. No manual operation is required, the whole machining process is fullyautomatic and lots of manpower resources can be saved.

Owner:日照金泰机械制造有限公司

An Image Processing Method for Rib Suppression in Chest X-ray DR Image

ActiveCN105125228BIncrease visual salienceFully automatic processing2D-image generationRadiation diagnosticsImaging processingDecomposition

The invention discloses an image processing method for chest X-ray DR (digital radiography) image rib inhibition. The method comprises the following steps: acquiring a chest X-ray DR image; performing pyramid decomposition on the DR image, performing a down sampling process to obtain a Gaussian image pyramid S, and performing an up sampling process to obtain a Laplacian image pyramid difference chart D(S); taking the minimum S as a current to-be-processed image I; performing filtering processing on the image I by using an adjustable Gabor filter bank so as to obtain a reconstructed image R; differencing the to-be-processed image I and the reconstructed image R to obtain a processing result image E with weakened segment-shaped textures under the scale; and doubling the processing result image E, adding the processing result image E and a corresponding Laplacian image pyramid difference chart D(S) under the size together, and repeating the processing procedure until the size is the same as that of an original DR image, thereby obtaining an image after rib inhibition. According to the method disclosed by the invention, the visual saliency of pulmonary shadows is improved, the workload of doctors is reduced, automatic processing can be realized, and an analysis conclusion is more objective and stable.

Owner:SICHUAN UNIV

Industrial robot for gear machining

InactiveCN113579373AHigh degree of automationHigh degree of intelligenceManipulatorGear-cutting machinesMachining processManufacturing engineering

The invention discloses an industrial robot for gear machining. The industrial robot comprises an outer shell, wherein a No.1 cavity with an upward opening is obliquely formed in the outer shell; a plurality of blanks are placed in the No.1 cavity; a transfer cavity communicates with the lower side surface of the No.1 cavity; and a driving cavity is formed in the left side surface of the transfer cavity. The industrial robot is high in automation degree, is capable of fully-automatically machining the blanks, and has the processes of feeding, machining, returning and the like; the intelligent degree of the gear rolling field in the market is improved; the blanks are machined through a rolling process; compared with traditional machining processes of gear shaping, gear hobbing and like, the rolling process has the advantages that the machining speed is high and the blanks can be machined in batches; and a mechanical arm is clamped through a pneumatic device and the pneumatic device can be separated from the mechanical arm, so that the feeding operation can be facilitated.

Owner:厦门珍雪科技有限公司

Coking waste water treatment method and A/O technology apparatus

InactiveCN102417272BSet the spacing wellThe cracking effect is goodTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentElectrolysisNitration

The invention is an improvement of a coking waste water treatment method. The method comprises steps of oil removal, impurity removal, electrolytic disintegration and A / O technology, and is characterized in that a biological hydrolysis acidification is set after electrolytic disintegration and before A / O technology; the electrolytic disintegration is electrode energizing aerobic strong electrolysis; the A / O technology employs butterfly jet aerators that are arranged in large intervals and have circulating pumps; the waste water is treated with aeration, aeration stopping and forced internal circulation, stationary deposition and water draining period processing successively, so as to realize biological oxidation and nitration-denitrification in a same pool. Cooperative effects and coordination of each technology increase treatment effect, and treated outlet water can stably reach COD no more than 100mg / l and NH3-N no more than 15 mg / l; besides, land occupation is saved undera same treating capacity and is only 80% of that of a common technology; operating cost of per ton of water is low; and a treatment effect is stable.

Owner:江苏新纯江环保工程有限公司

Full-automatic treatment device for saw blade central holes

PendingCN107186487AGuaranteed accuracyImprove processing efficiencyMetal sawing tool makingOther manufacturing equipments/toolsStructural engineeringWorkbench

The invention provides a full-automatic treatment device for saw blade central holes. The full-automatic treatment device for saw blade central holes solves the technical problems that an existing saw blade process is low in efficiency and bigger in occupation area, and labor is wasted. The full-automatic treatment device for saw blade central holes is provided with a working table, which is provided with a feeding device, a reaming machine, a chamfering machine and a material arrangement device in turns, and the working table is further provided with a saw blade walking groove; a saw blade walking block is arranged inside the working table and below the saw blade walking groove; a bulge is formed in the saw blade walking block which drives a saw blade to move on the saw blade walking groove through the bulge, and the upper portion of the working table and the lower portions of the reaming machine and the chamfering machine are connected to a press plate through a press plate cylinder; the press plate is provided with press pate holes. The full-automatic treatment device for saw blade central holes can be used for processing and treating the saw blade central holes.

Owner:SHANDONG HEIXUANFENG SAW IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com