Quick manufacturing process of rotational moulding machine die

A manufacturing process and rotomolding machine technology, which is applied in the field of rapid manufacturing process of rotomolding machine molds, can solve the problems of many processing equipment and machine tools, cumbersome process, high cost, and achieve high flexibility, accurate acquisition of surface area, and reduced cycle and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

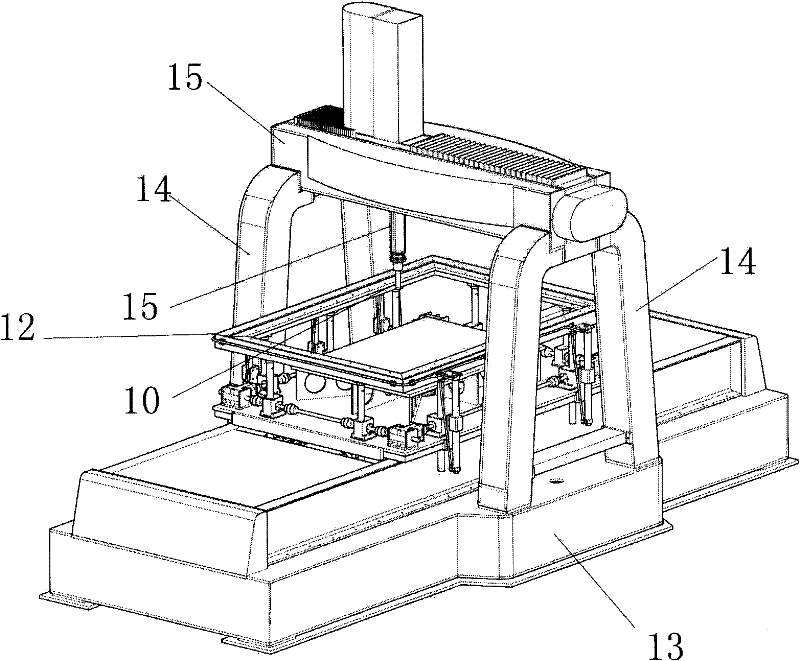

[0025] Below in conjunction with accompanying drawing, the specific content of the novelty of the present invention will be further described.

[0026] The rapid manufacturing process of the rotomolding machine mold comprises the following steps:

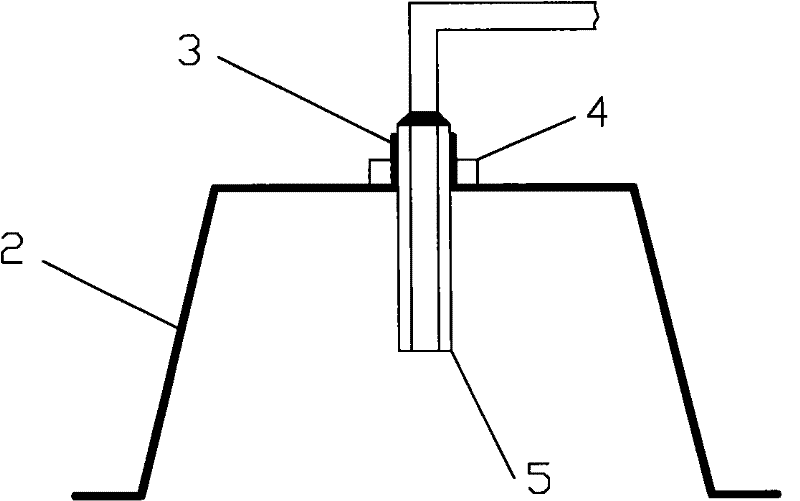

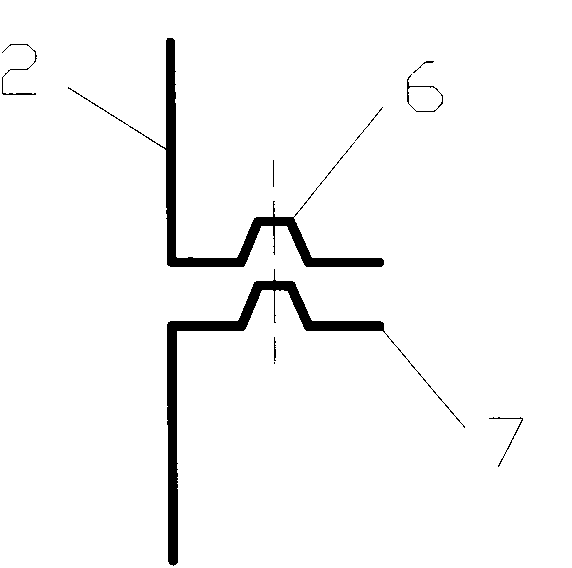

[0027] A. Model generation: According to the shape of the upper and lower molds of the rotational molding machine mold, use a three-dimensional CAD system to design the contour models of the upper and lower molds of the rotational molding machine mold, and add flanges to the edges of the upper and lower mold contour models 7 model, the model of positioning pin or tongue and groove 6 is set on the flange 7, and the model of the boss 3 used to form the measurement pressure relief hole is set on the upper mold contour model; finally, the three-dimensional CAD model of the rotomolding machine mold is generated ;

[0028] B. Adjusting parameters: According to the requirements for the lines 11 used to increase the frictional force on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com