Full-automatic sample pretreatment device and treatment method

A kind of sample pretreatment, fully automatic technology, applied in the field of analytical chemistry, can solve the problem of time-consuming, laborious, complex, large error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

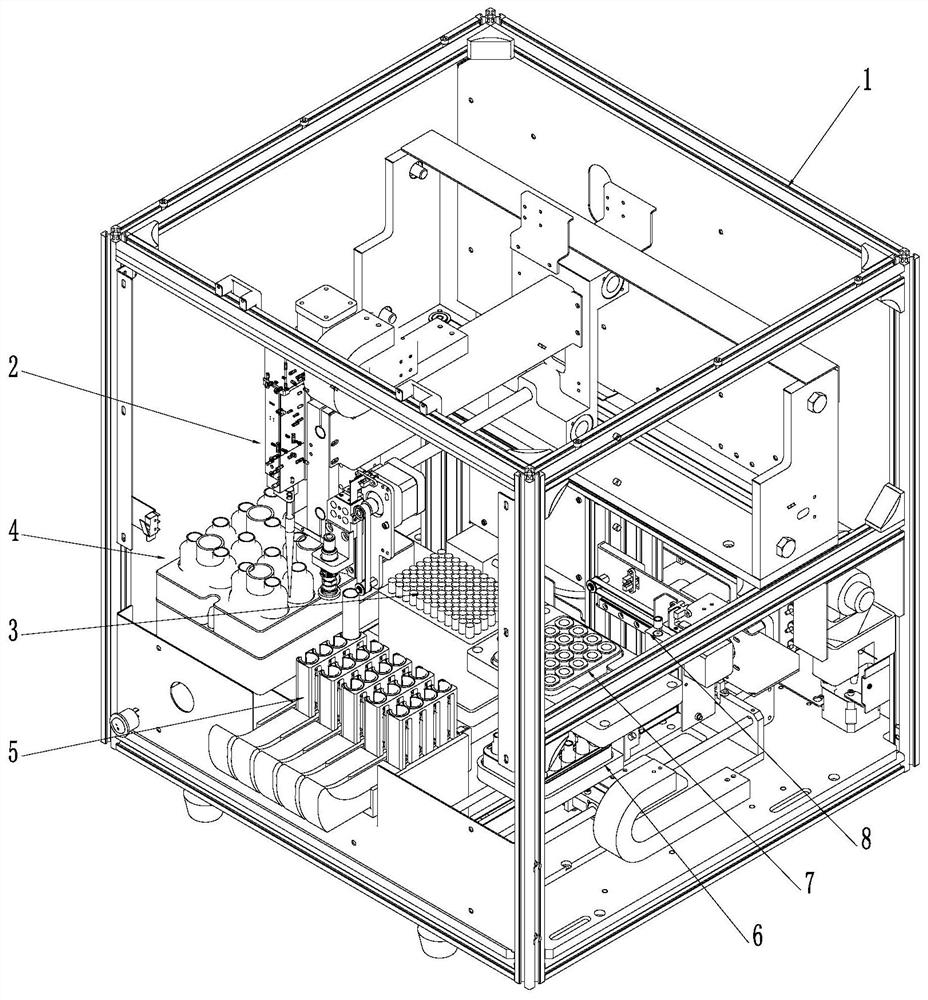

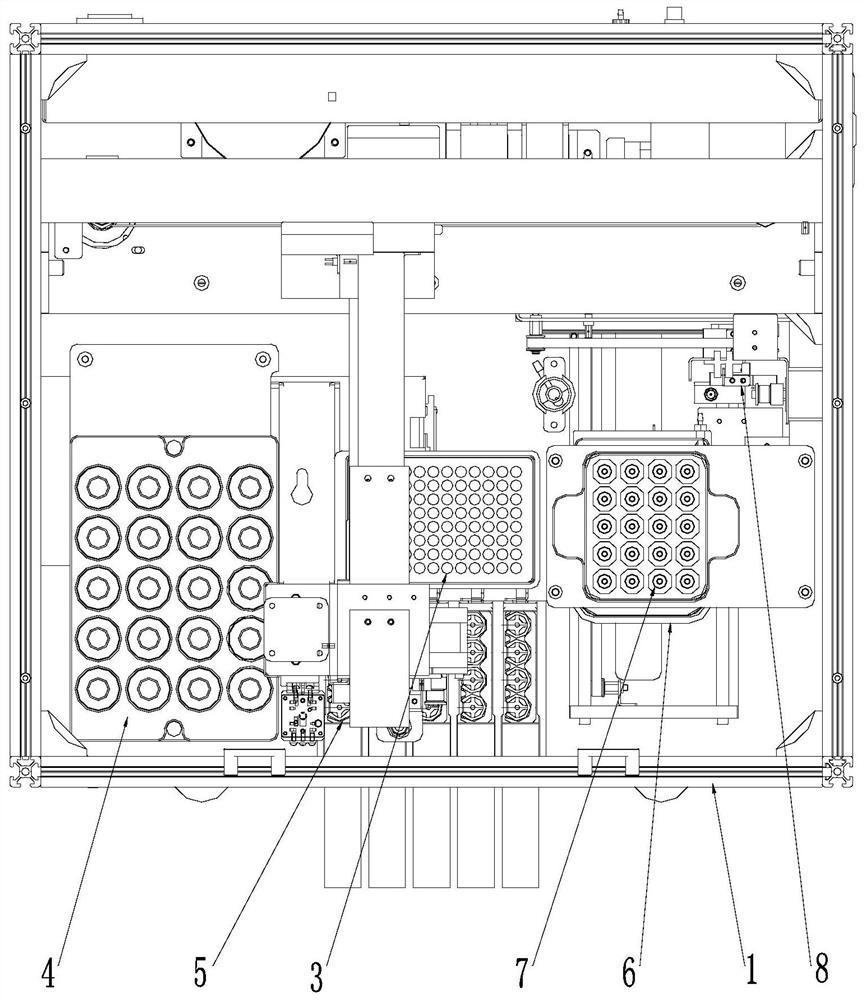

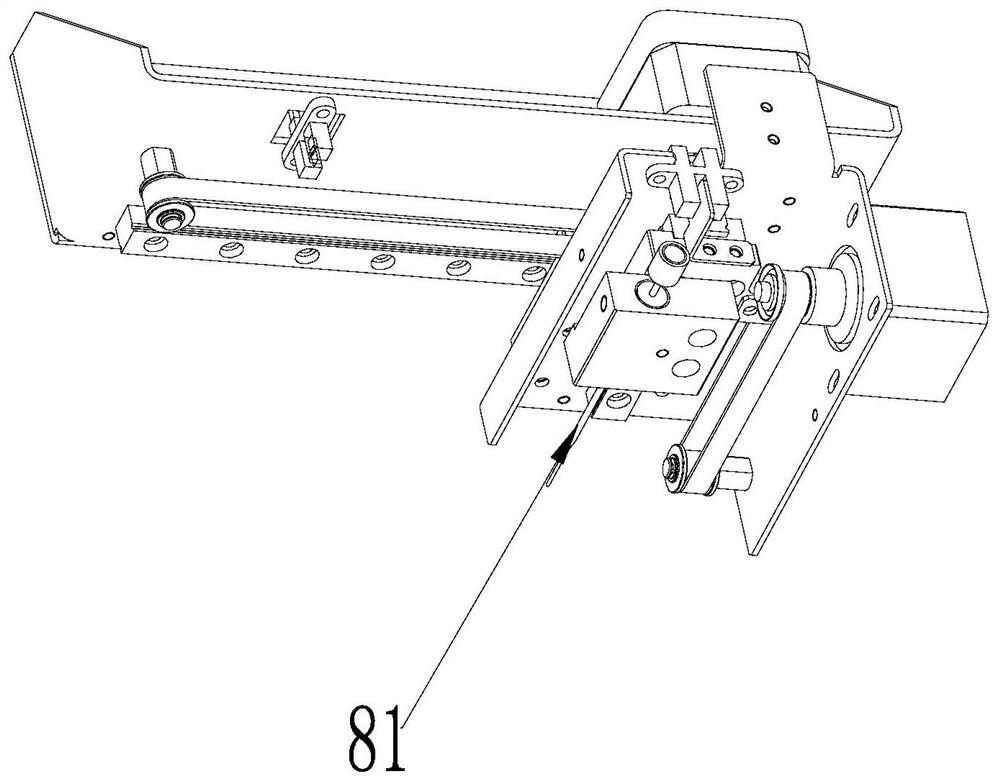

[0041] see Figure 1 to Figure 9, is a specific embodiment of a fully automatic sample pretreatment device. The fully automatic sample pretreatment device includes an installation frame 1, a sampling and processing module 2, a tip box module 3, a reagent tray module 4, a sample tray module 5, a collection module 6, an extraction module 7, a sampling module 8, and an operation control module , generally, the six peripheral surfaces of the installation frame are respectively provided with detachable connection sealing plates to form a shield for the inner space of the installation frame 1 . The tip box module 3, the reagent tray module 4, the sample tray module 5, and the collection module 6 are arranged in the hollow lower part of the installation frame 1, and the collection module 6 is driven by the first transmission mechanism to move along the X-axis direction, so The extraction module 7 includes a filter column tube carrier 71 for shelving the filter column tube, which is ...

Embodiment 2

[0043] The method for sample processing using the fully automatic sample pretreatment device of embodiment 1 comprises the following steps:

[0044] 1) Place the sample tube containing the vancomycin blood sample, the reagent bottle containing the vancomycin extract, the 3ml extraction column, and the collection bottle in the sample tray module, reagent tray module, extraction module, and collection module, respectively, for The sample valve is connected to the infusion pump of the chromatograph, and the operation control module sets the corresponding processing method;

[0045] 2) The sampling and processing module moves to the top of the reagent tray module, the sampling mechanism is inserted into the corresponding reagent bottle, quantitatively absorbs 900ul of the corresponding reagent, and then transfers it to the extraction column corresponding to the extraction module or the collection bottle corresponding to the collection module;

[0046] 3) The sampling and processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com