Full-automatic treatment device for saw blade central holes

A technology for processing devices and center holes, which is applied in the manufacture of cutting tools for sawing devices, metal sawing equipment, maintenance and safety accessories, etc., can solve the problems of wasting labor, low efficiency, and large footprint, and achieve strong integrity and Guaranteed accuracy and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

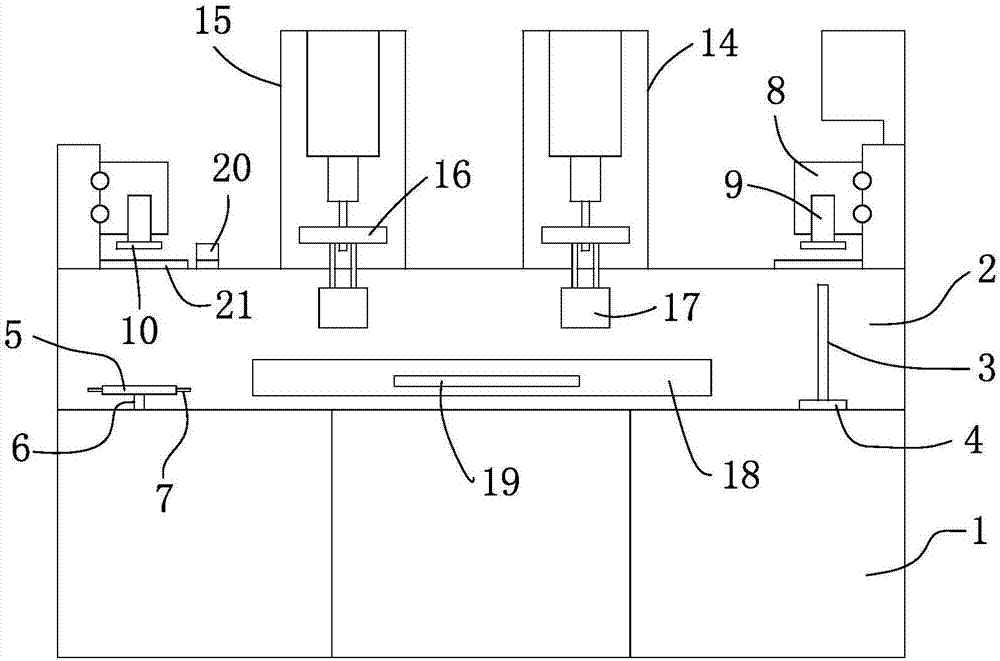

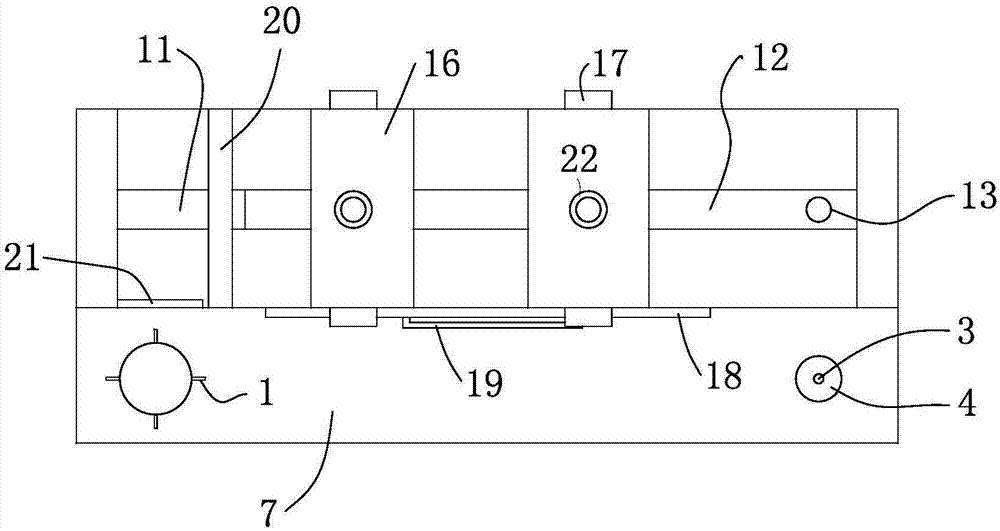

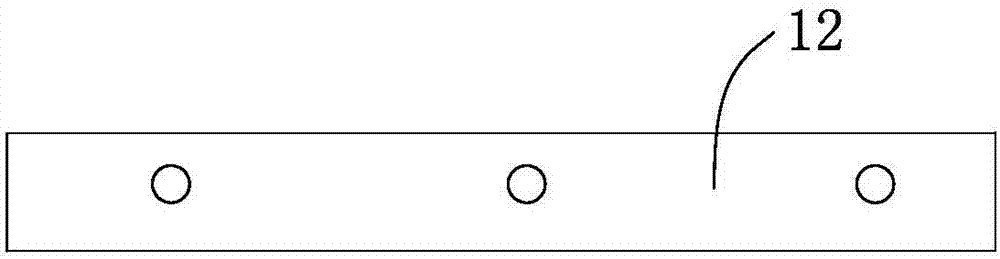

[0019] Such as figure 1 As shown, the present invention is provided with a material table 1 and a working table 2, one end of the material table 1 is provided with a storage rod 3, and the bottom of the storage rod 3 is provided with a gasket 4. The operator sets the rough-processed saw blade on the storage rod 3, which is convenient for the reclaiming device on the workbench 2 to take materials; the other end of the material table 1 is provided with a discharge table 5, which is disc-shaped , its lower end is fixed with a screw rod 6, and the screw rod 6 is connected with the material platform 1 through threads. The discharge table 5 is used to place the saw blades after processing. By rotating the discharge table 5, the height of the discharge table 5 can be adjusted, so that the amount of material that can be discharged on the discharge tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com