Automatic trimming system for wood veneers

A trimming and finishing technology, which is applied in the field of automatic trimming system of wood veneer, can solve problems such as low efficiency and impact on trimming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described and understood by non-limiting examples below.

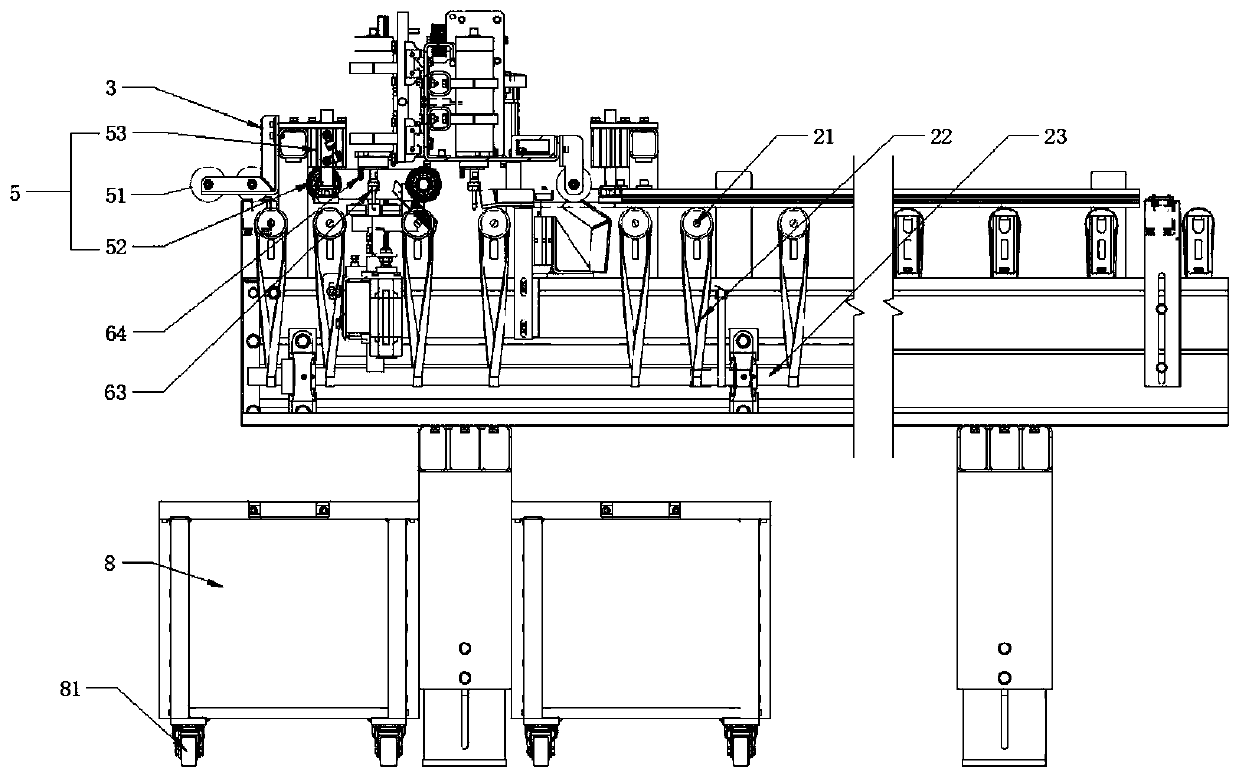

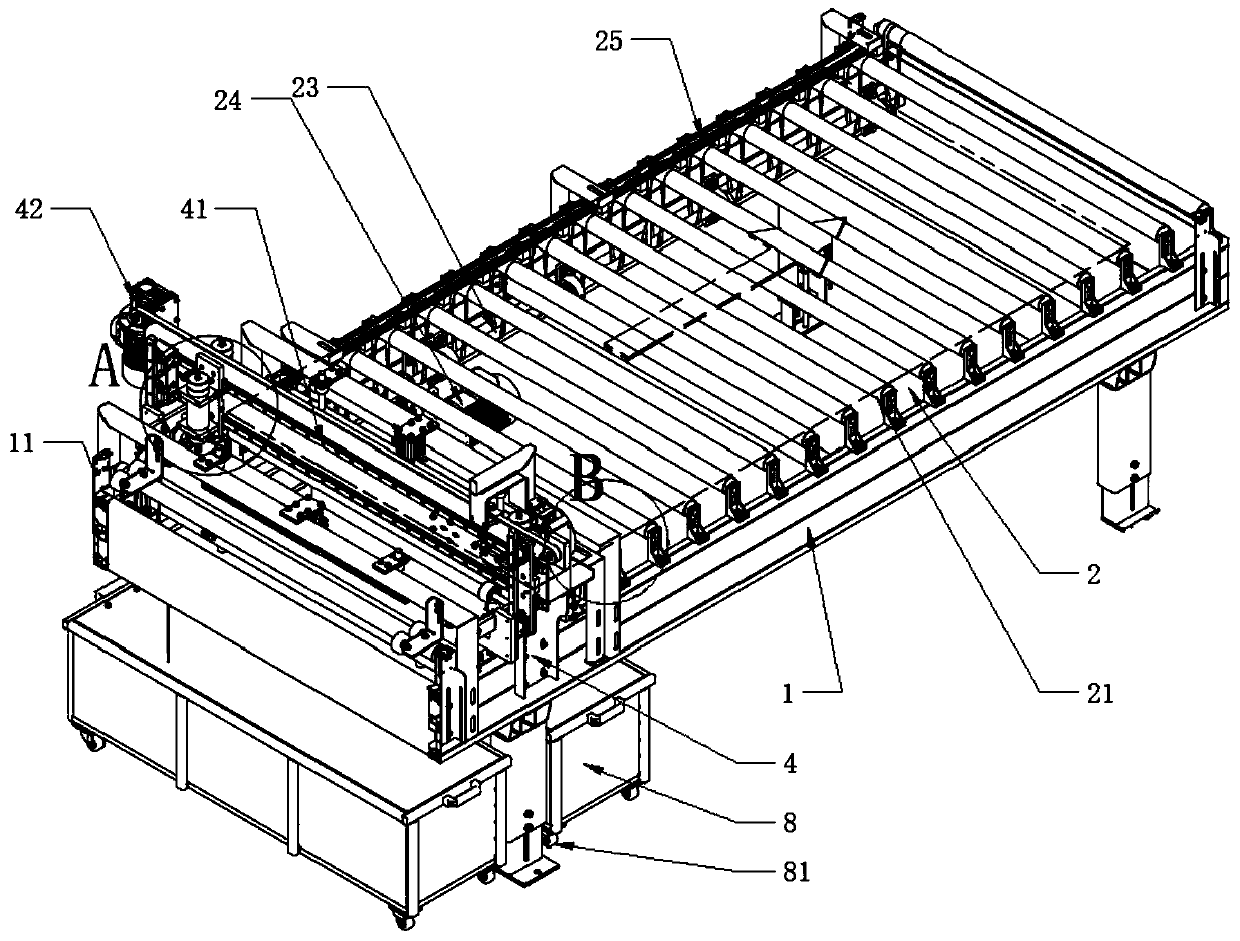

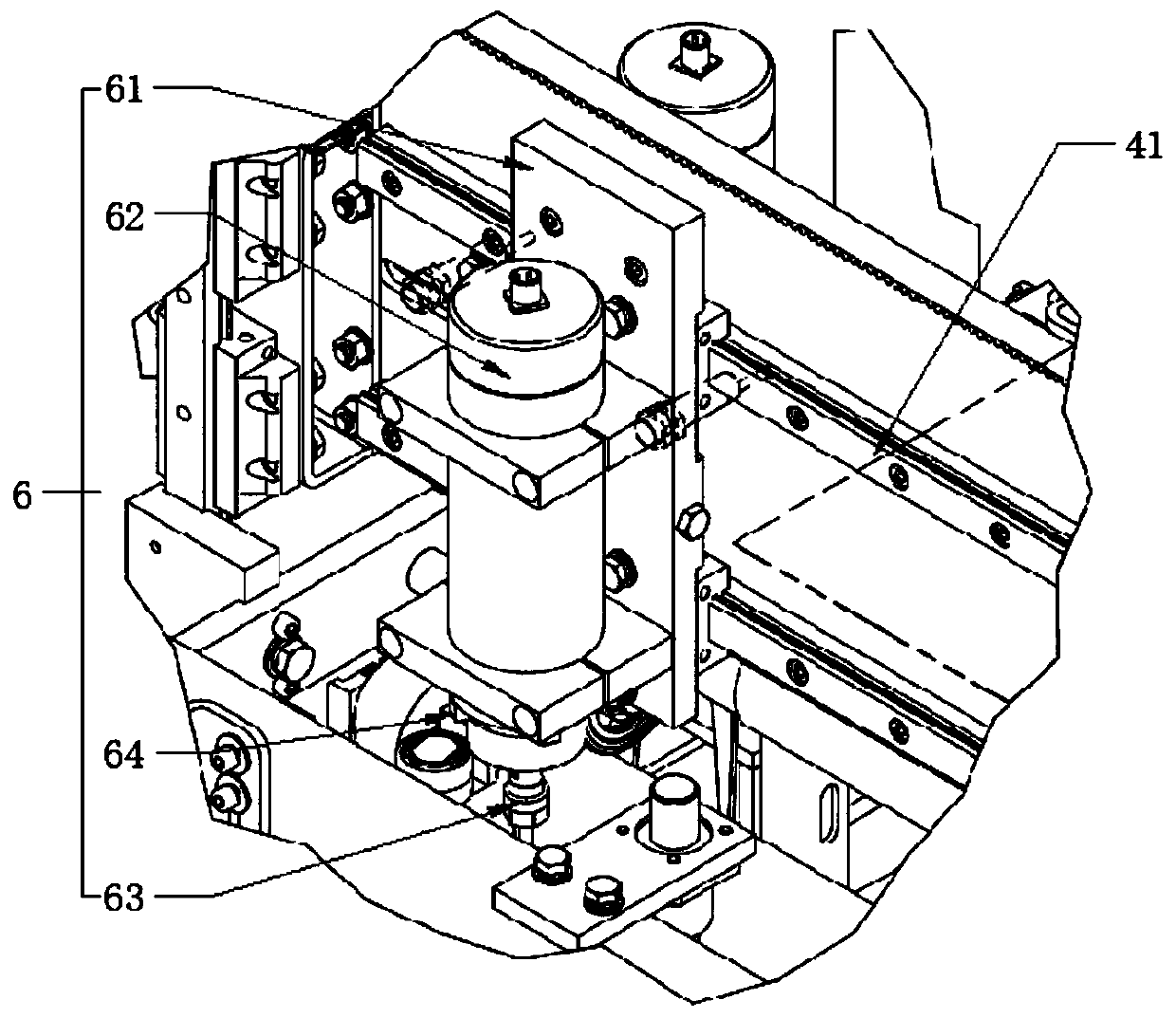

[0019] Such as Figure 1-4 As shown, the present invention is an automatic trimming system for wood veneer, including a frame, two sets of feeding auxiliary components 5, a trimming component for trimming veneer, and a waste recycling component. The frame includes a frame body 1 , a roller table 2 composed of several conveying rollers 21 fixedly installed side by side on the frame body 1, a feeding auxiliary press frame 3 and a gantry frame 4 arranged at the entrance of the roller table 2 in sequence; the feeding auxiliary pressing frame 3 and The gantry 4 is fixedly installed on the frame body 1, and a main motor 24 is arranged below the frame body 1, and the main motor 24 is fixedly arranged on the frame body 1, and the conveying rollers 21 are respectively connected to the transmission shaft 23 through the conveying belt 22, The transmission shaft 23 is fixedly installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com