Virtual program control temperature test instrument

A technology of testing instruments and temperature sensors, which is applied in the direction of instruments, thermometers, simulators, etc., can solve the problems of inability to automatically generate temperature rise test reports of electromechanical products, lack of communication interfaces, single functions, etc., and achieve easy portability and high test accuracy. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

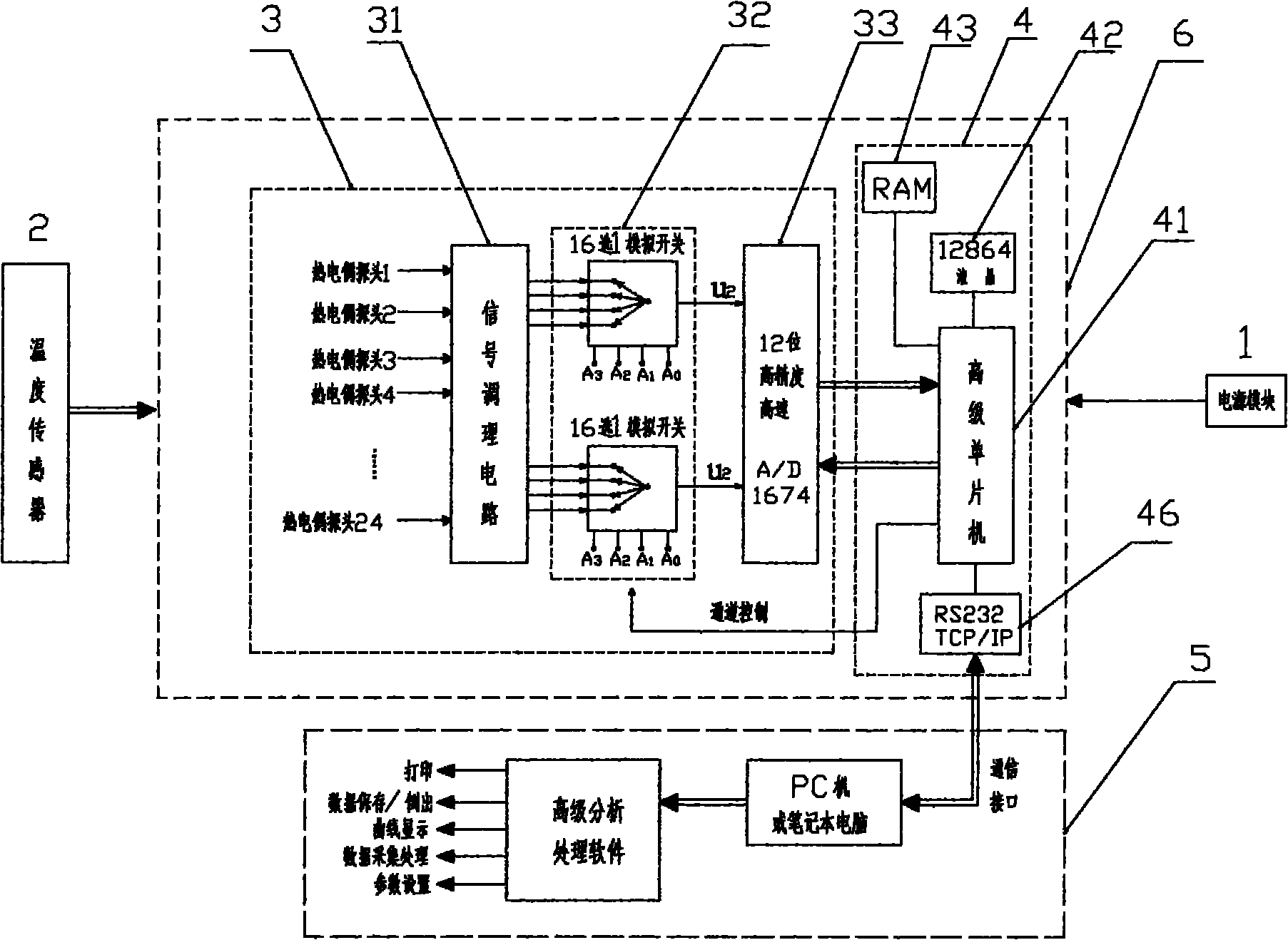

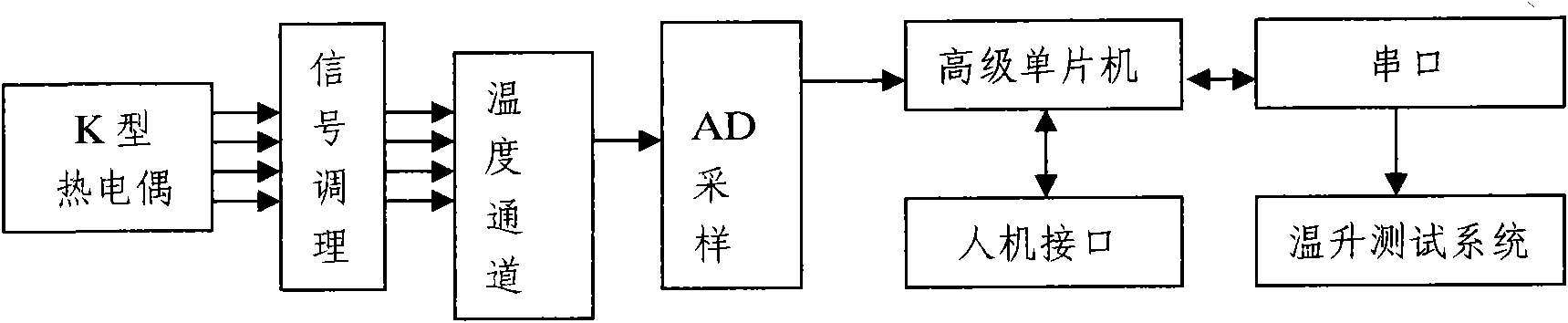

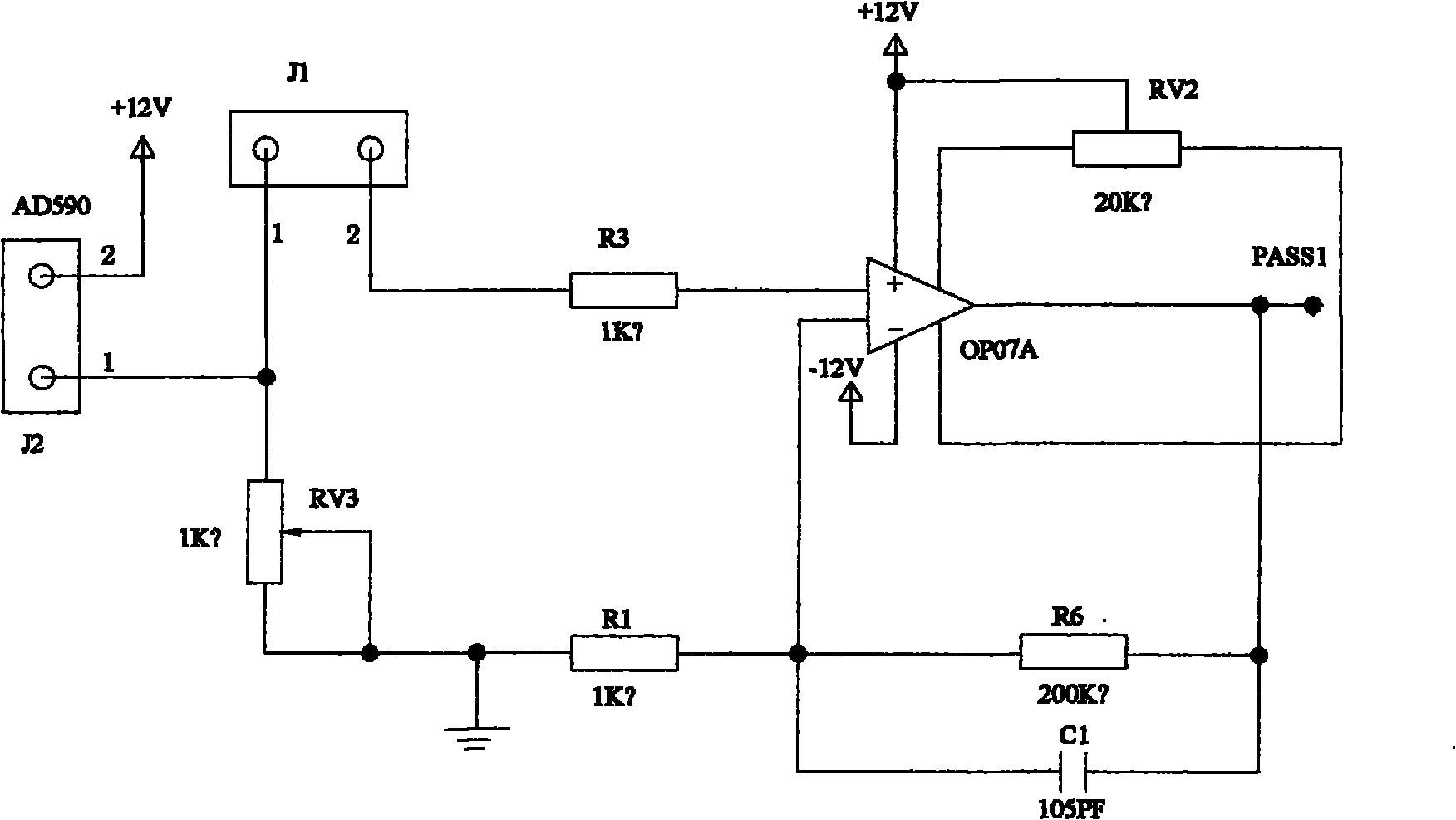

[0016] Such as figure 1 with figure 2 As shown, a virtual program-controlled temperature testing instrument of the present invention is mainly composed of a power supply module 1 , a temperature sensor 2 , a temperature acquisition terminal 6 and a host computer 5 . The temperature acquisition terminal 6 includes a signal conditioning module 3 and a serial port to Ethernet module 4, the signal conditioning module 3 includes a signal conditioning circuit 31, an analog switch 32 and an A / D chip 33, and the serial port to Ethernet module 4 includes a single-chip microcomputer 41, a single-chip RAM memory 43. Liquid crystal display 42 and serial port server 46, temperature acquisition terminal 6 is responsible for the sensing and detection of temperature signals, signal conditioning, analog channel switching, A / D conversion, dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com