High-precision grinding device for inner diameter of metal pipe

A metal pipe, high-precision technology, applied in the direction of grinding drive device, grinding/polishing safety device, metal processing equipment, etc., can solve the problems affecting the health of workers, polluting the environment, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

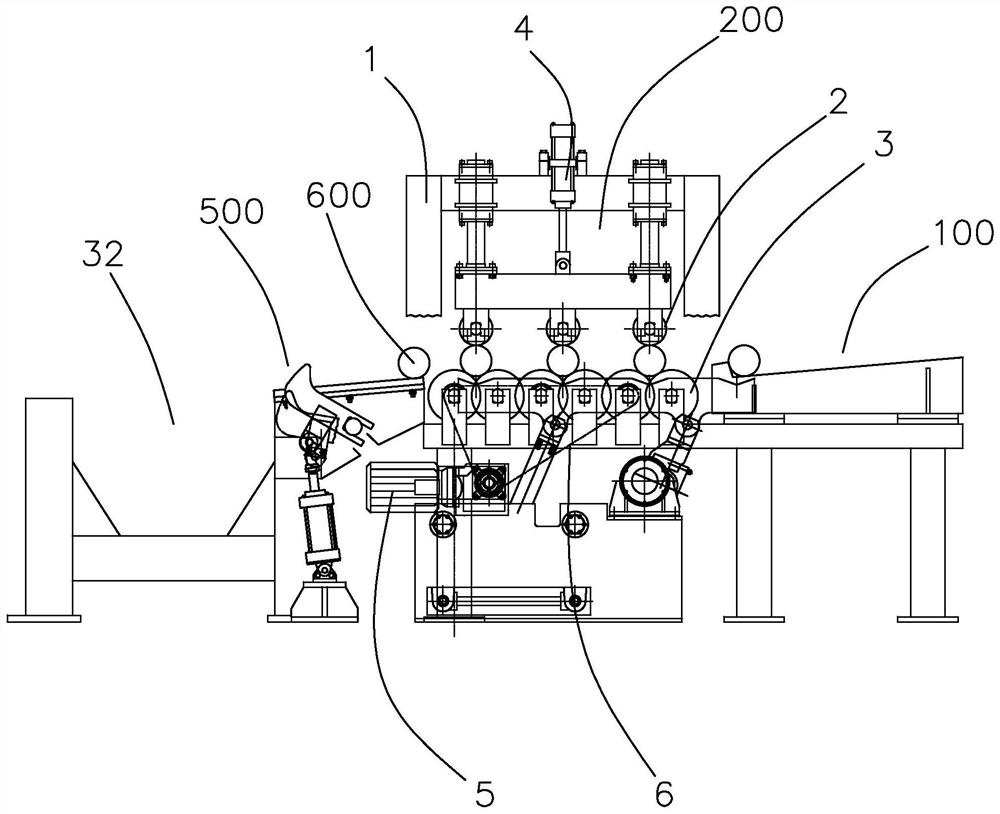

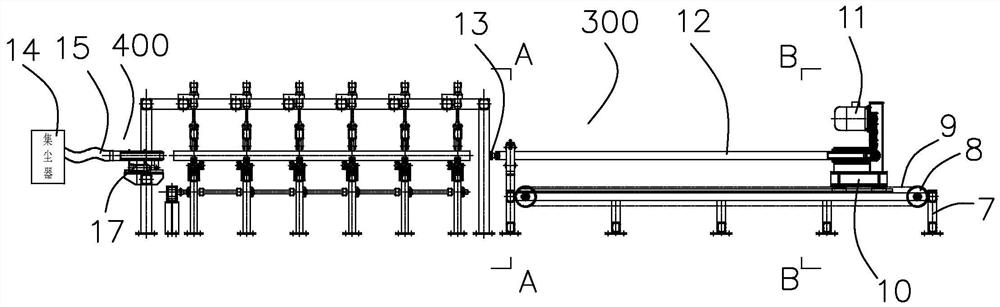

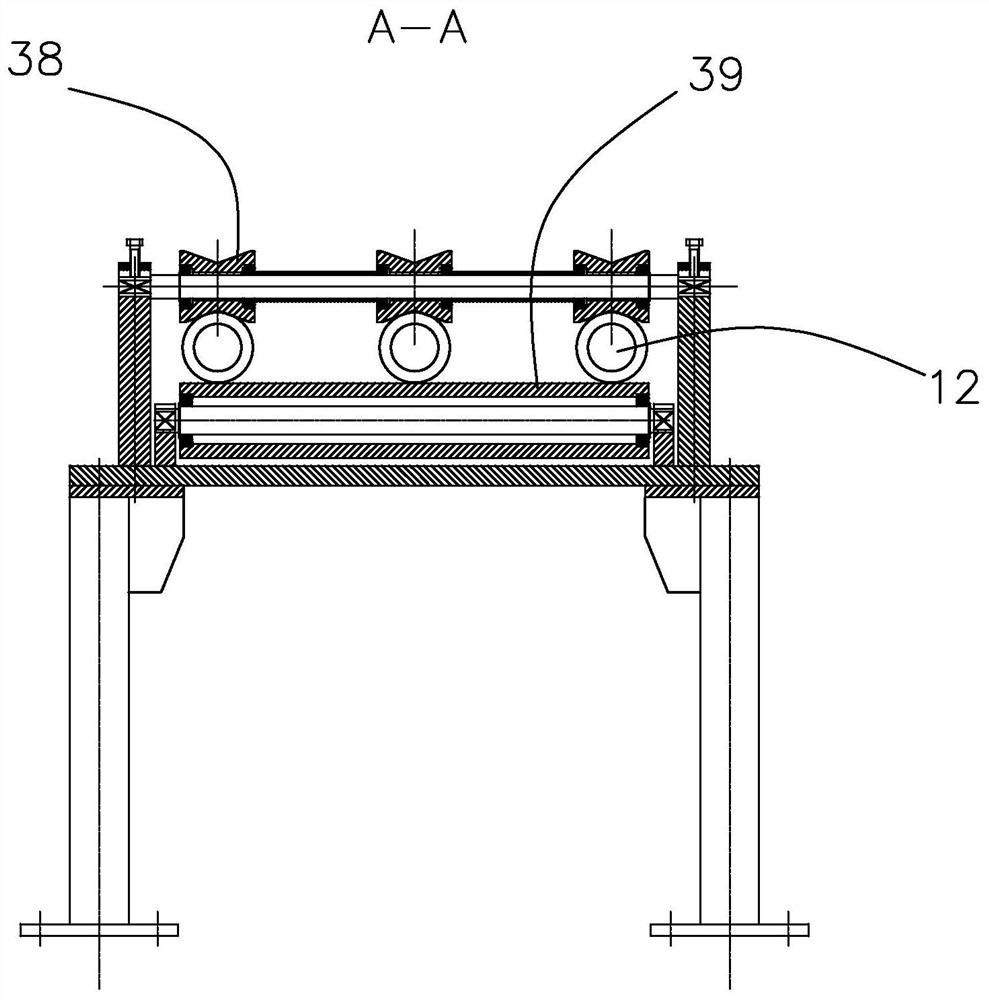

[0030] Such as Figure 1-Figure 15As shown, a high-precision metal pipe inner diameter grinding device provided by the present invention includes a feeding mechanism 100, a pressing mechanism 200, a grinding mechanism 300, a dust collecting mechanism 400, and a blanking mechanism 500. The pressing mechanism 200 includes There is a main frame 1 and a plurality of pressing rollers 2 arranged on the main frame 1, and a plurality of rotating roller shafts 3 are arranged on the main frame 1, and the pressing rollers 2 are correspondingly arranged directly above two adjacent rotating roller shafts 3 , powered by the pressing cylinder 4, in this embodiment, there are three pressing rollers 2, six corresponding rotating roller shafts 3, and two adjacent rotating roller shafts directly below the pressing rollers 2 3 Form three focus points for supporting the pipe material 600, the rotating roller shaft 3 is driven by the first motor 5 and the first belt 6; one side of the main frame 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com