Large-size half-coil-pipe jacket glass lining reaction vessel

A glass-lined and reactor technology, applied in the field of reactors, can solve the problems of small size, no cooling tube, and difficult temperature control in the kettle, and achieve the effect of large volume, reasonable overall structure and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

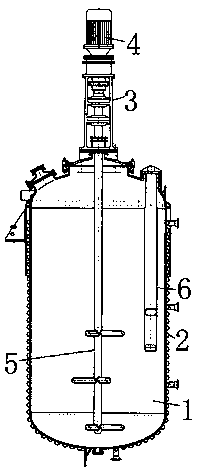

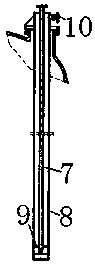

[0013] Such as figure 1 with figure 2 As shown, the large-scale half-coil jacketed glass-lined reactor of the present invention includes a reactor body 1, a half-coil 2 is arranged outside the reactor body 1, and a There is a frame 3, and a motor 4 is arranged on the frame 3, and the motor 4 is connected with the paddle agitator 5, and the bottom of the paddle agitator 5 is arranged in the reaction kettle body 1, and on the frame The reaction kettle body 1 next to the 3 is provided with a cooling group pipe 6, and the cooling group pipe 6 is arranged in the reaction kettle body 1, and the cooling group pipe 6 includes an intermediate inlet pipe 7 and an outer sleeve pipe 8, and their joints For closed connection, a connecting plate with holes 9 is provided at the inner lower part of the outer casing 8, the middle inlet pipe 7 is connected with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com