Hydraulic-acoustic streaming cavitation microbubble generator and working method thereof

A technology of micro-bubble generator and bubble generator, applied in chemical instruments and methods, mixing methods, fluid mixers, etc. Obtain the flotation effect and other issues, achieve the effect of strong adaptability, improve mineral separation effect, and improve equipment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

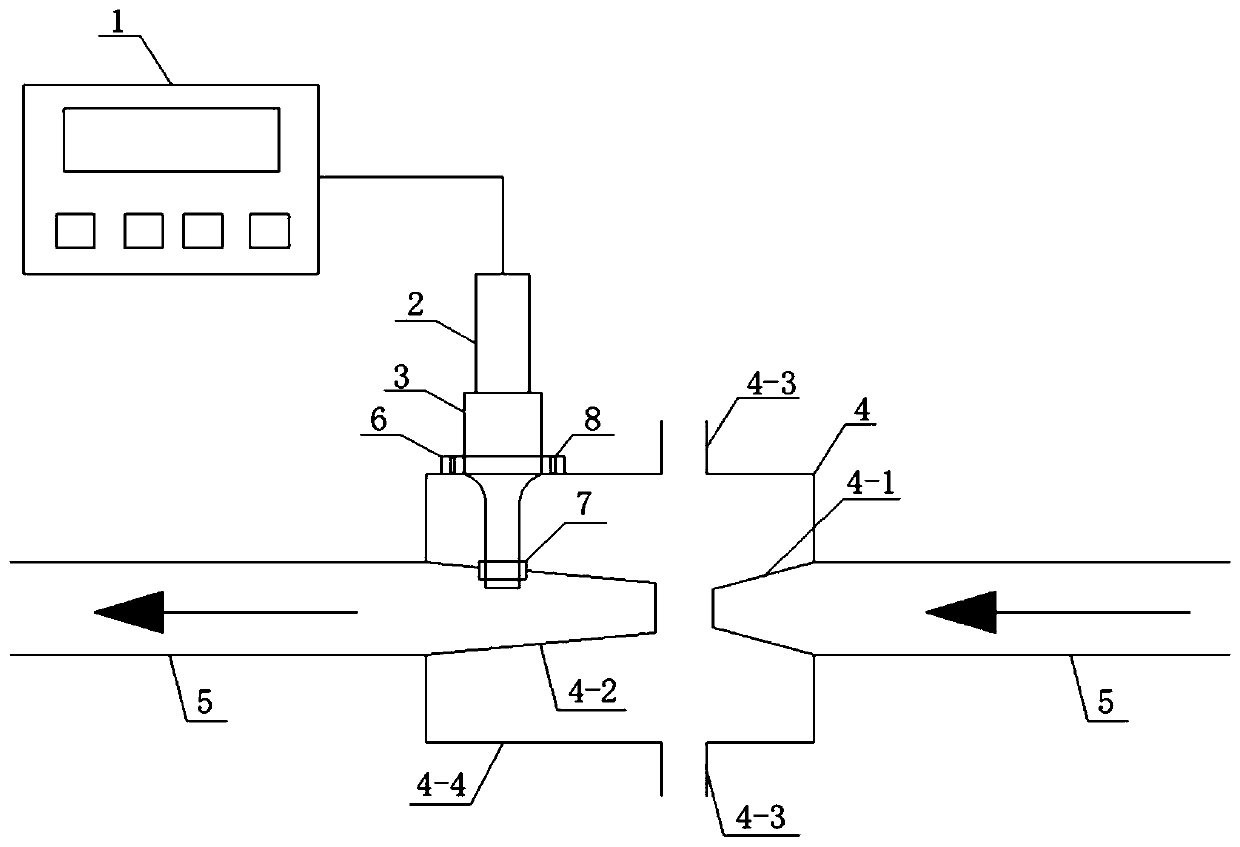

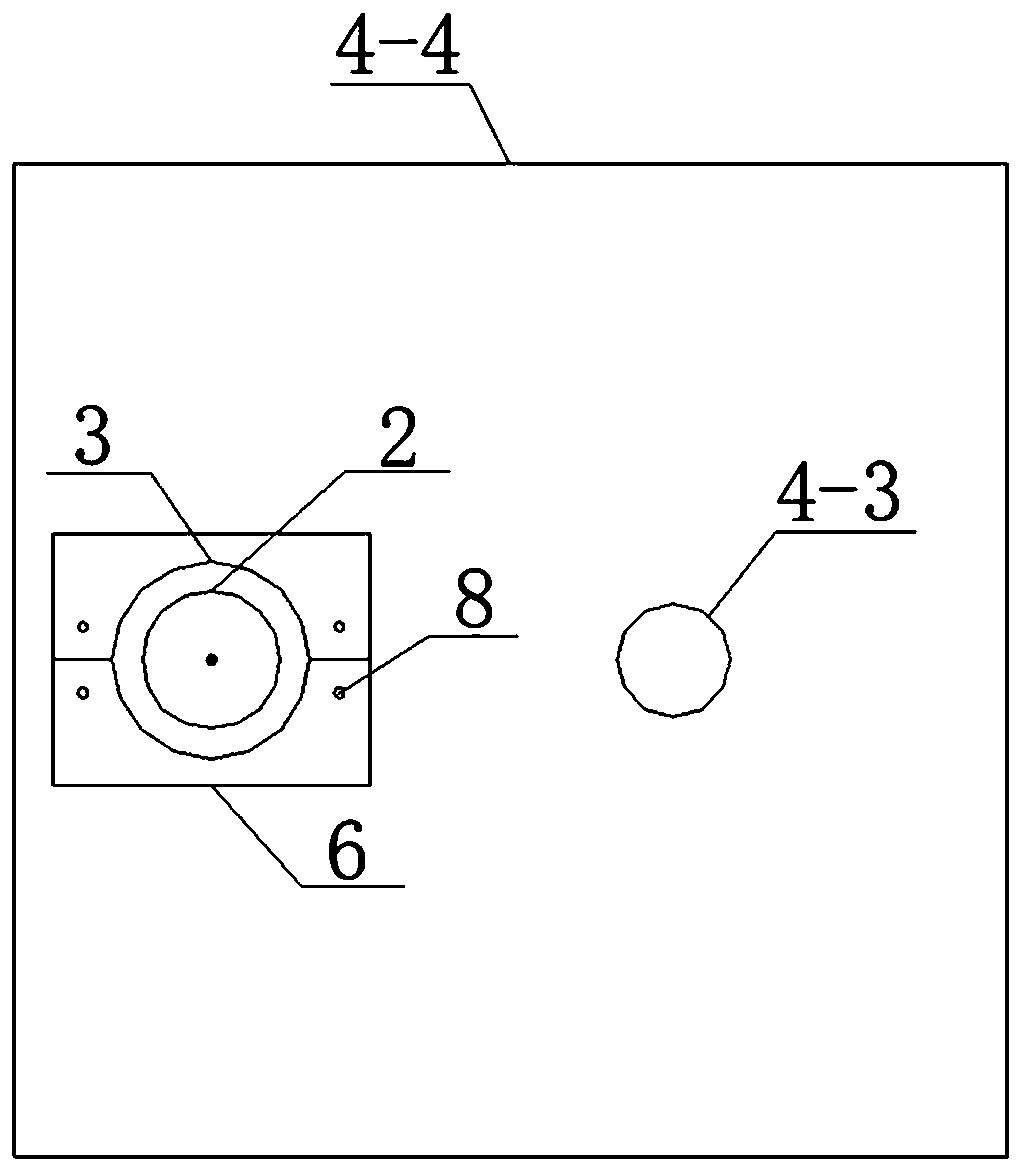

[0025] Such as figure 1 with figure 2 As shown, the hydraulic-acoustic flow cavitation microbubble generator of the present invention is characterized in that: it comprises a square Venturi tube bubble generator and an ultrasonic generator, and the Venturi tube bubble generator 4 comprises a square housing 4-4 , the square housing 4-4 is provided with an air inlet 4-3 opposite to each other up and down, and the left and right sides of the square housing 4-4 are oppositely provided with two pipelines 5, wherein one pipeline 5 is in the Venturi tube bubble generator 4 is provided with a contraction zone pipeline 4-1 inside, and another branch pipeline 5 is provided with a divergence zone pipeline 4-2 inside the Venturi tube bubble generator 4, a contraction zone pipeline 4-1 and a divergence zone pipeline 4- 2 are arranged oppositely, and jus...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap