Gas-liquid driven cleaning device

A cleaning device and gas-liquid technology, which is applied in the field of oil drilling, can solve the problems of inability to use the gas source of injection parts, narrow application range, and low safety, etc., and achieve the effects of strong impact, reduced noise, and large water outlet area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

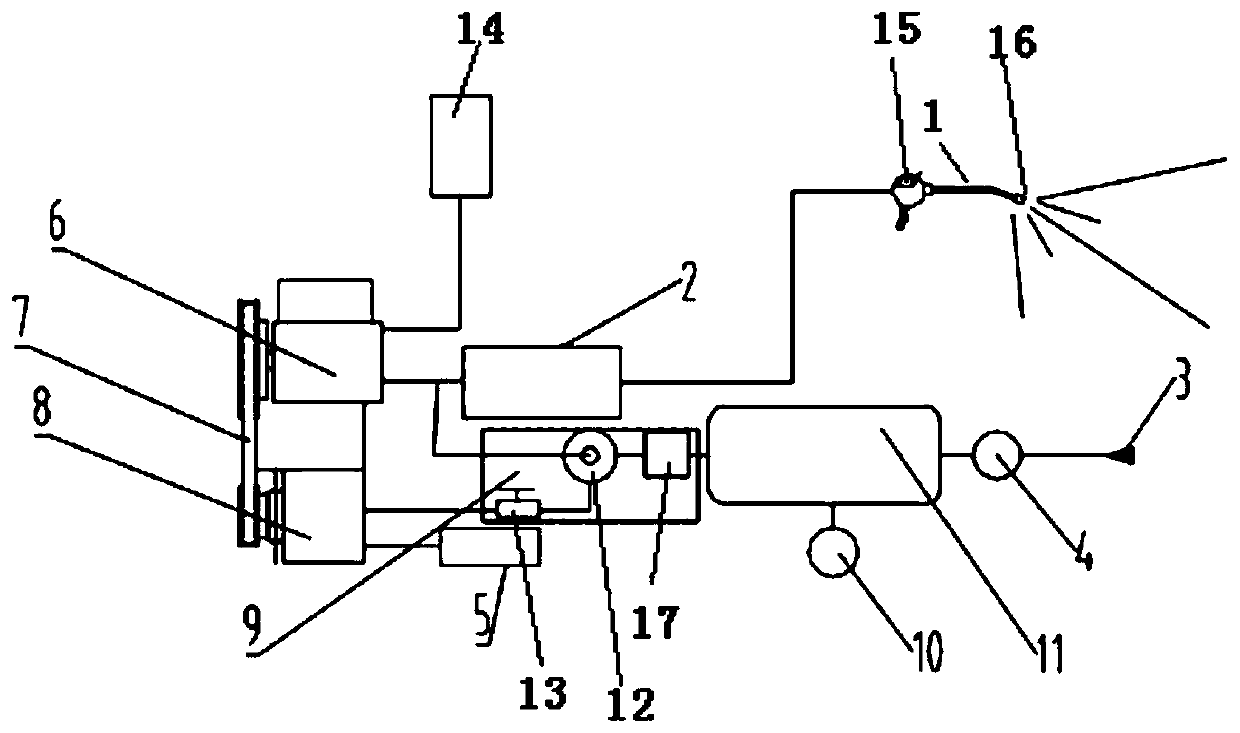

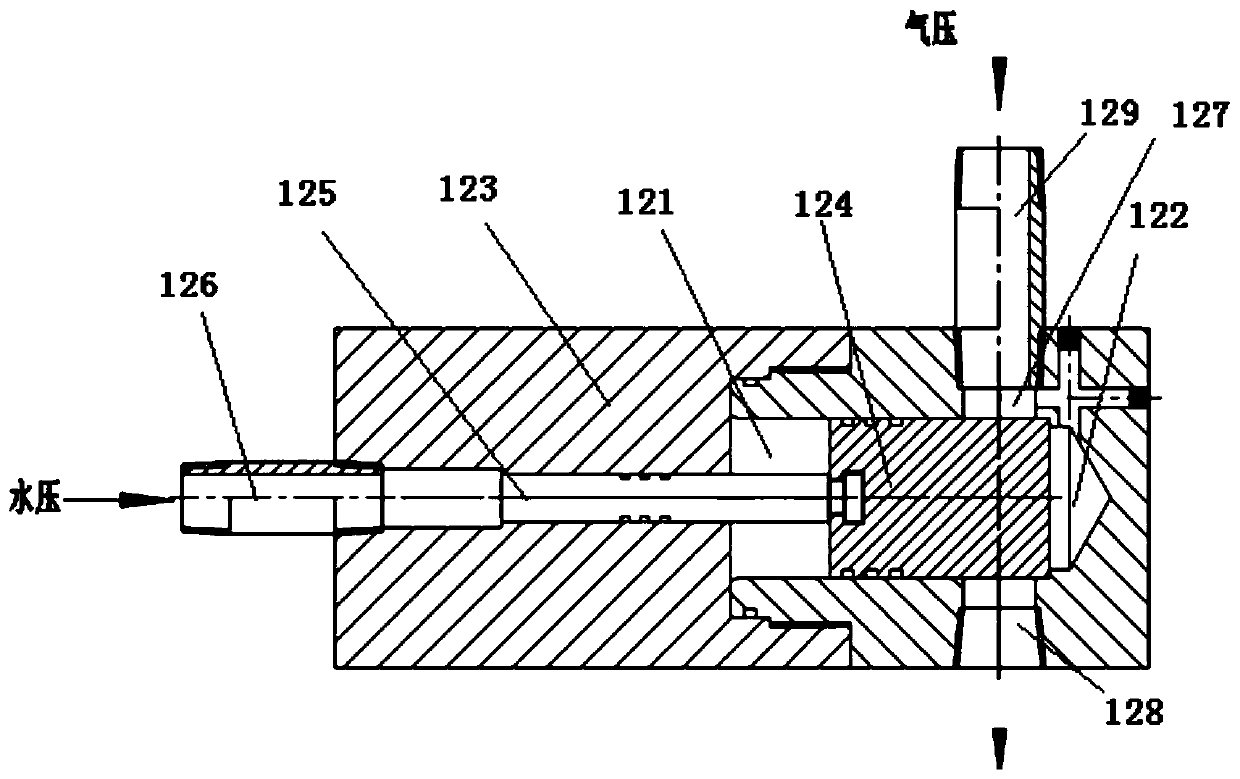

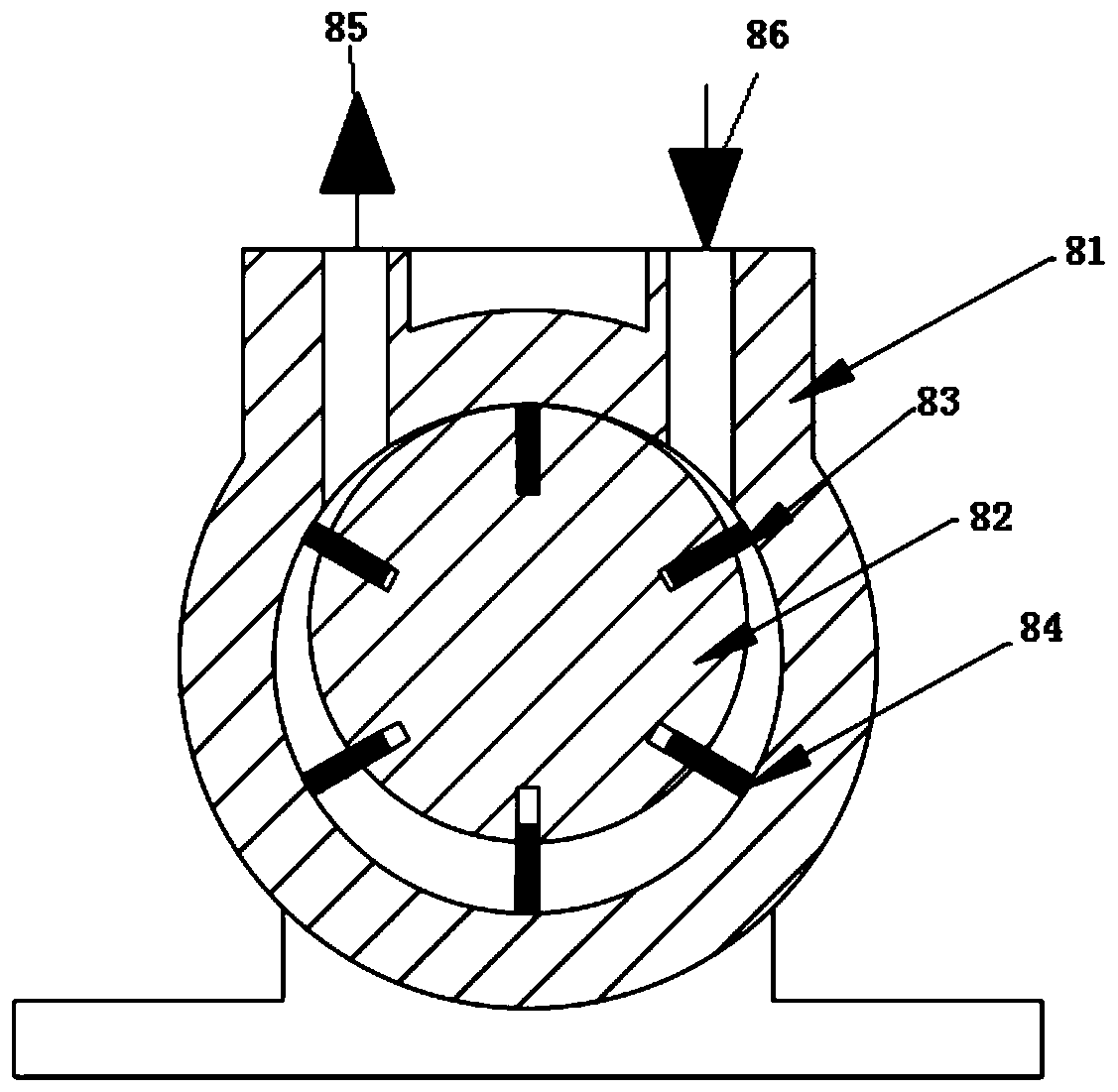

[0034] Examples, see attached Figure 1-2 , a gas-liquid driven cleaning device, which includes a gas power unit 3, the gas power unit is connected to a gas buffer 11, an air filter 4 is also arranged between the two, and a gas-liquid indicator 10 is arranged on the gas buffer, The gas flow controller 9 is connected to the rear end of the gas buffer, and the gas flow controller includes an automatic liquid balance device 12 and a flow control valve 13. The automatic liquid balance device includes a housing 123 with a cavity inside the cavity. A piston 124 is provided, and the piston divides the cavity into an upper chamber 121 and a lower chamber 122. A piston rod 125 is provided on one side of the piston, and a hydraulic head 126 is provided at the other end of the piston rod. Air port 127 and air outlet 128, the air inlet is provided with air pressure head 129, the air inlet and the air outlet are controlled conduction or disconnection by the piston, its lower cavity is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com