A hinged double propulsion beam propulsion mechanism

A propulsion mechanism and propulsion beam technology, applied in the direction of drill pipe, casing, drill pipe, etc., can solve the problems of affecting the construction progress, low drilling efficiency, fast drilling speed of down-the-hole drilling, etc., to solve the problems of high labor intensity, The effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments. The front and rear directions in this document are the front end in the direction of propulsion during actual use;

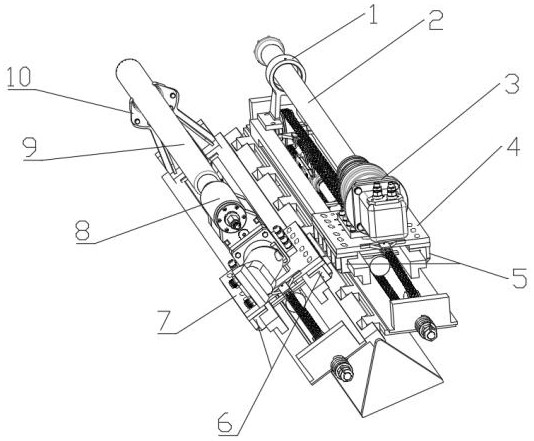

[0020] Such as figure 1 Shown, a kind of hinge type double propulsion beam propulsion mechanism, described hinge type double propulsion beam propulsion mechanism comprises propulsion beam structure, down-the-hole drilling system, water grinding drilling system;

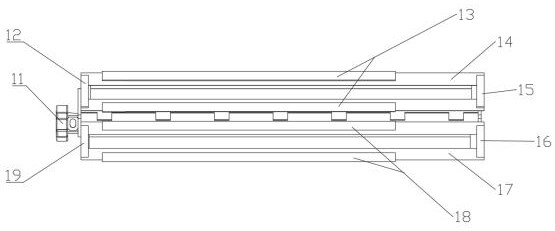

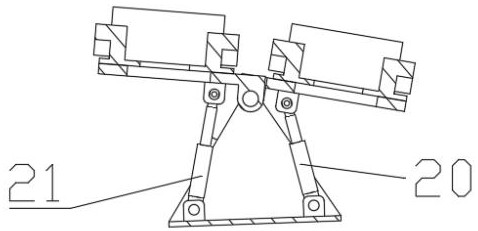

[0021] The propulsion beam mechanism is used to propel the down-the-hole drilling system and the water milling drilling system to the face drilling; figure 2 , image 3 , the propulsion beam structure includes a propulsion beam support 22, a propulsion beam, a top 11, a guide rail, a fixed pulley mounting plate, and an opening and closing oil cylinder; the appearance of the propulsion beam support 22 is an isosceles triangle; the bottom is connected by a steel plate, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com