Integral rotating type gas-water-slag separation track car with separation box and barrel

A gas-water slag and rotary technology, which is applied in the direction of drainage, mining fluid, gas discharge, etc., can solve the problems of unfavorable safety of workers, vulnerability to pneumoconiosis, and hidden dangers of workers' health and safety, and achieves good separation effect and easy operation. Lightweight, easy to move effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

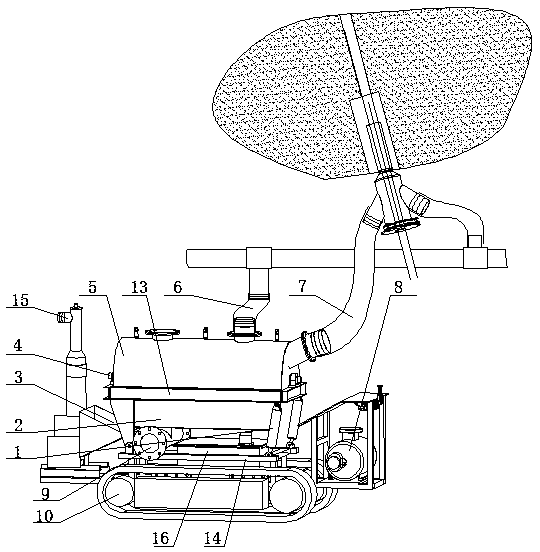

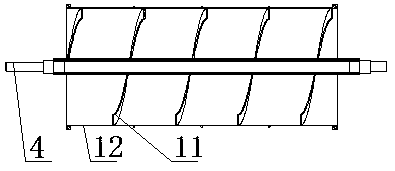

[0028] As shown in the figure, an air-water slag separation crawler trolley with integral rotation of the separation box includes an air-water slag separation system. The air-water slag separation system includes a separation box, a power source, and is installed on the separation box. The connecting pipeline connected with the negative pressure drainage pipeline, the center of the separation box is horizontally pierced with a transmission shaft 4, on which the auger blade 11 is welded along the helical direction of the axis, and the outer edge of the auger blade 11 is welded with Cylindrical filter screen 12, drive shaft 4, auger blade 11 and filter screen 12 are welded as a whole, and drive shaft 4 provides power to rotate through the power source, driving auger blade 11 and filter screen 12 to rotate as a whole, filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com