Intelligent multi-curved surface detecting system and method of railway vehicle

A rail vehicle and detection system technology, which is applied in the field of instrument part size detection, can solve problems such as cumbersome operation, low efficiency, and time-consuming, and achieve the effects of true measurement results, improved accuracy, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0027] An intelligent multi-curved surface detection system for rail vehicles, said system comprising:

[0028] Measurement module: used to detect the height value of the point to be measured on the bottom surface of the carriage;

[0029] Wireless receiving module: used to transmit the received data to the industrial computer;

[0030] Industrial computer: used for remote control measurement measurement module.

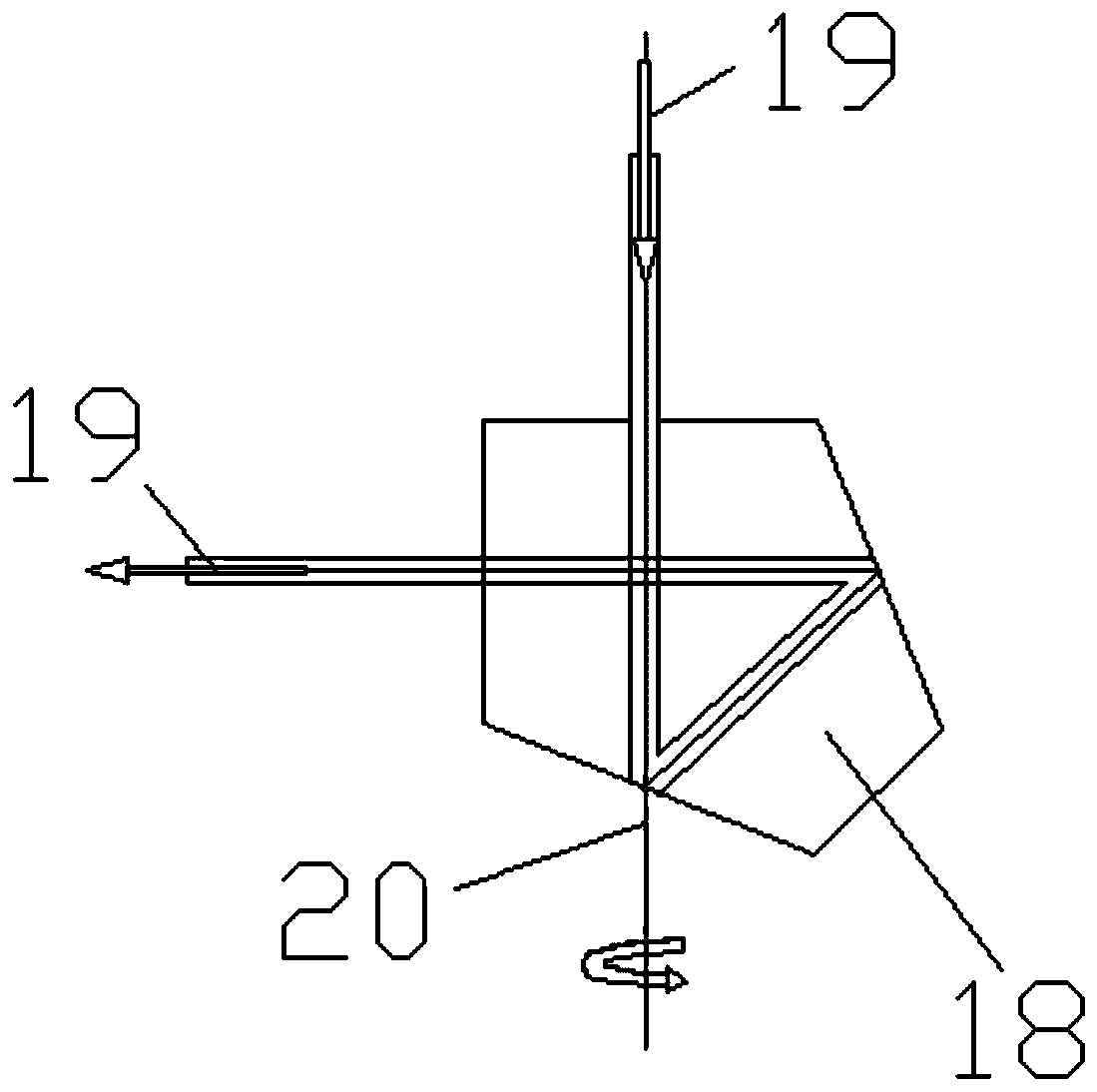

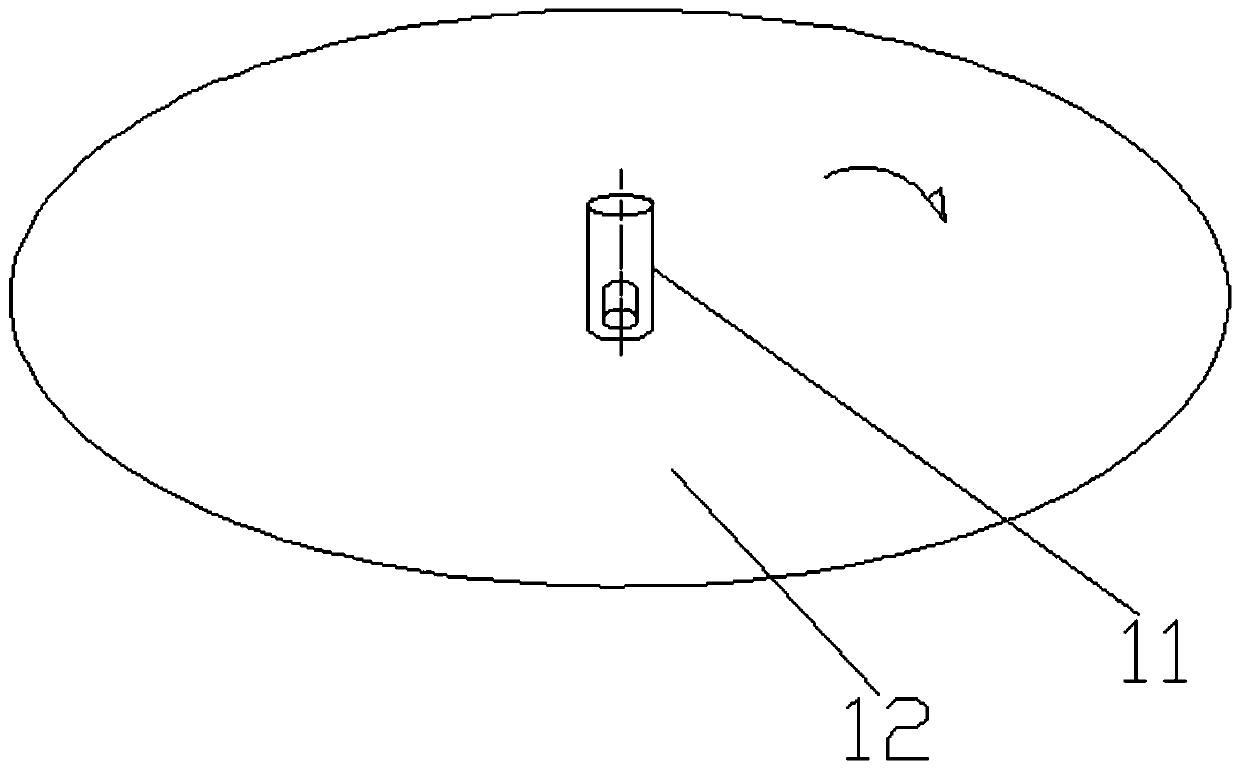

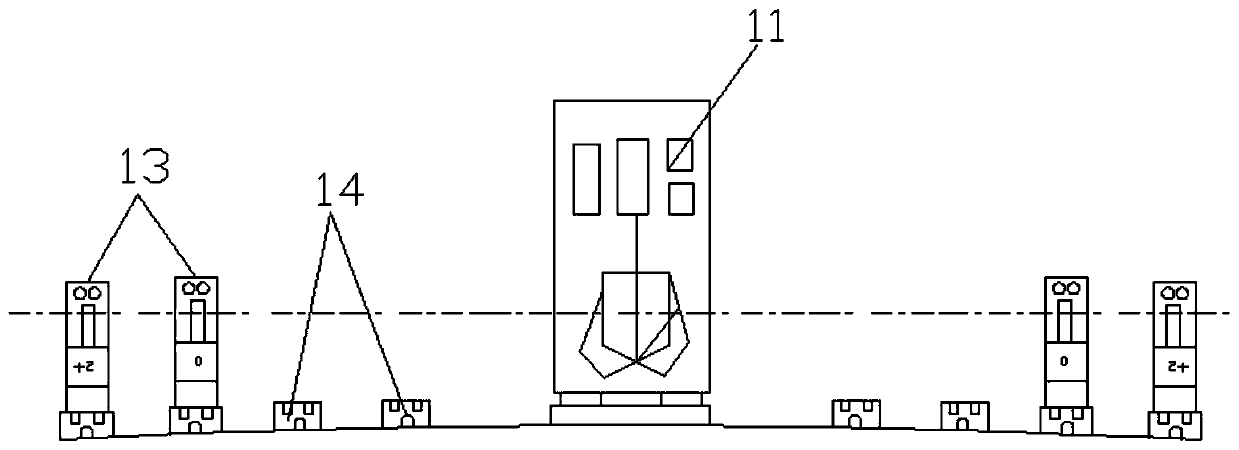

[0031] Specifically, the system further includes a measuring trolley 17; the measuring trolley 17 is used to carry measuring equipment. The measuring device includes a laser leveling device 11 and a photodetector 13; the laser leveling device 11 is used to generate a horizontal laser plane 12; the photodetector 13 is used to measure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com