Manual test base with upper slider structure

A technique of manual testing and testing the base, which is applied in the direction of electronic circuit testing, measuring electronics, measuring devices, etc. It can solve the problems of reducing test efficiency, affecting the test results of high-pixel optical chips, and increasing operating steps, so as to avoid partial extrusion of chips , Guarantee the reliability of the test and avoid the effect of relative deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

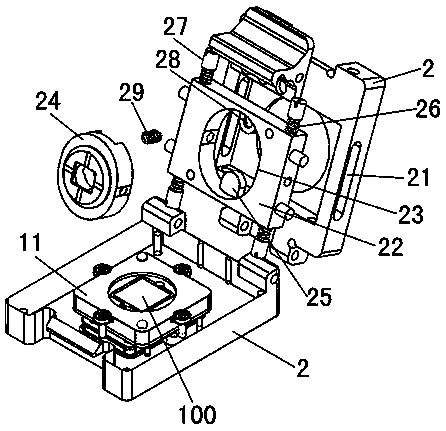

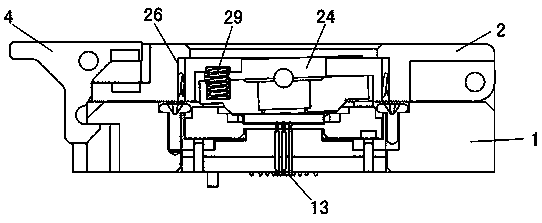

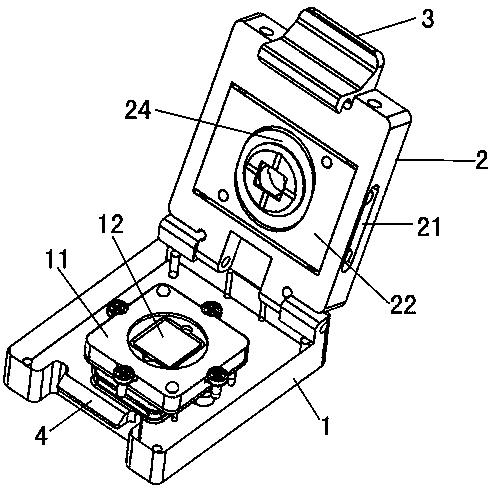

[0027] A manual test base provided with an upper slider structure, such as Figure 1-3 As shown, including the test base 1 and the upper cover 2.

[0028] Specifically, the upper cover 2 is hinged on one side of the test base 1 and can be flipped and pressed together with the test base 1. The test base 1 is provided with a floating plate structure 11. The floating plate structure is fixed to the test base by bolts, and the floating plate The plate structure is surrounded by a closed whole.

[0029] A chip groove 12 is provided in the floating plate structure 11 for setting the chip 100. The test probe 13 is also arranged in the floating plate structure and acts on the bottom side of the chip groove 12. Specifically, the test probe 13 is a micro-probe (POGO PIN) to export the signal of the product.

[0030] In order to realize that there is no relative between the chip and the pressure plate after the contact, the slide groove 21 at the side end of the sliding upper cover 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com