The Method of Improving the Precision of Automatic Packing System

A system precision, automatic packing technology, applied in general control systems, control/regulation systems, packaging, etc., can solve problems such as increased labor costs, impact on packing quality and efficiency, and decreased accuracy, and is convenient for later maintenance and rectification. , The method is simple and easy to operate, and the effect of reducing the measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

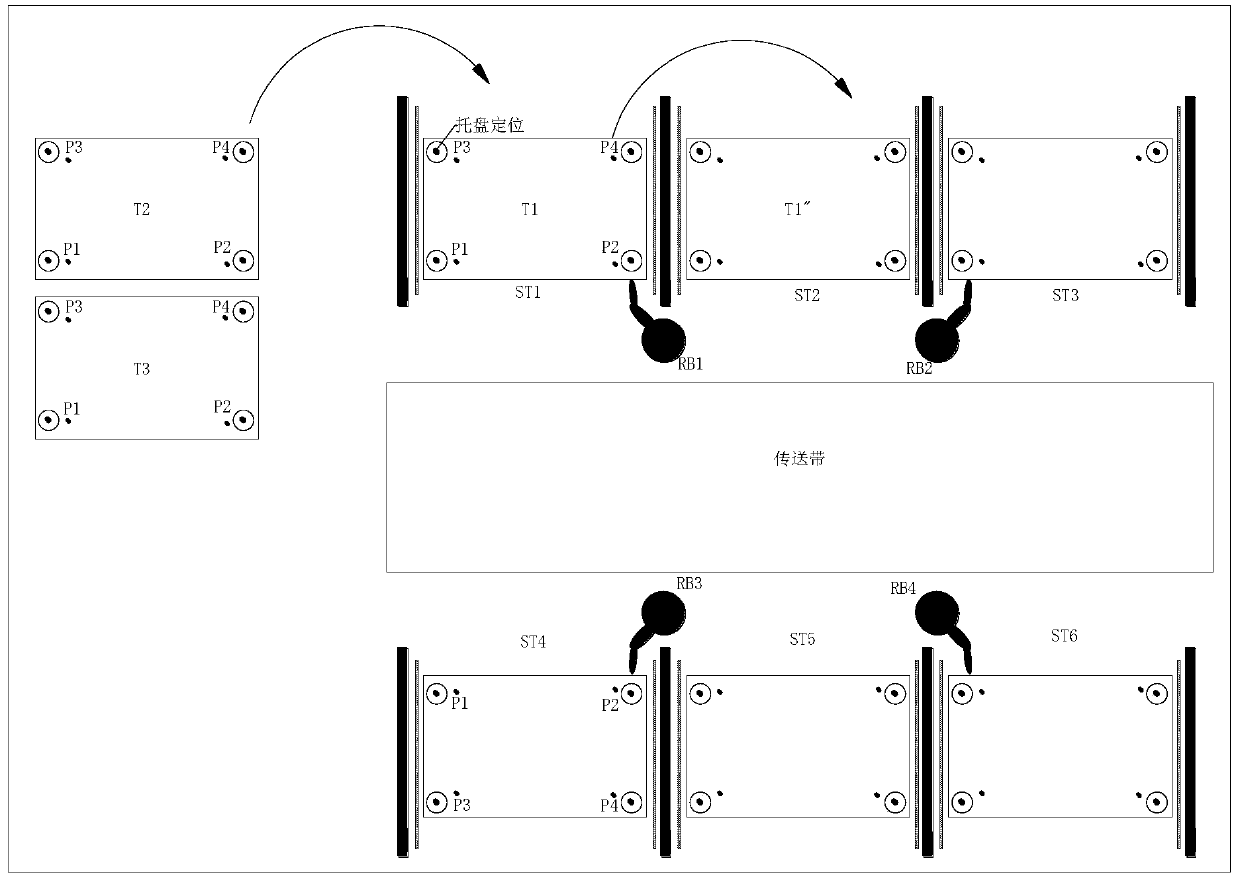

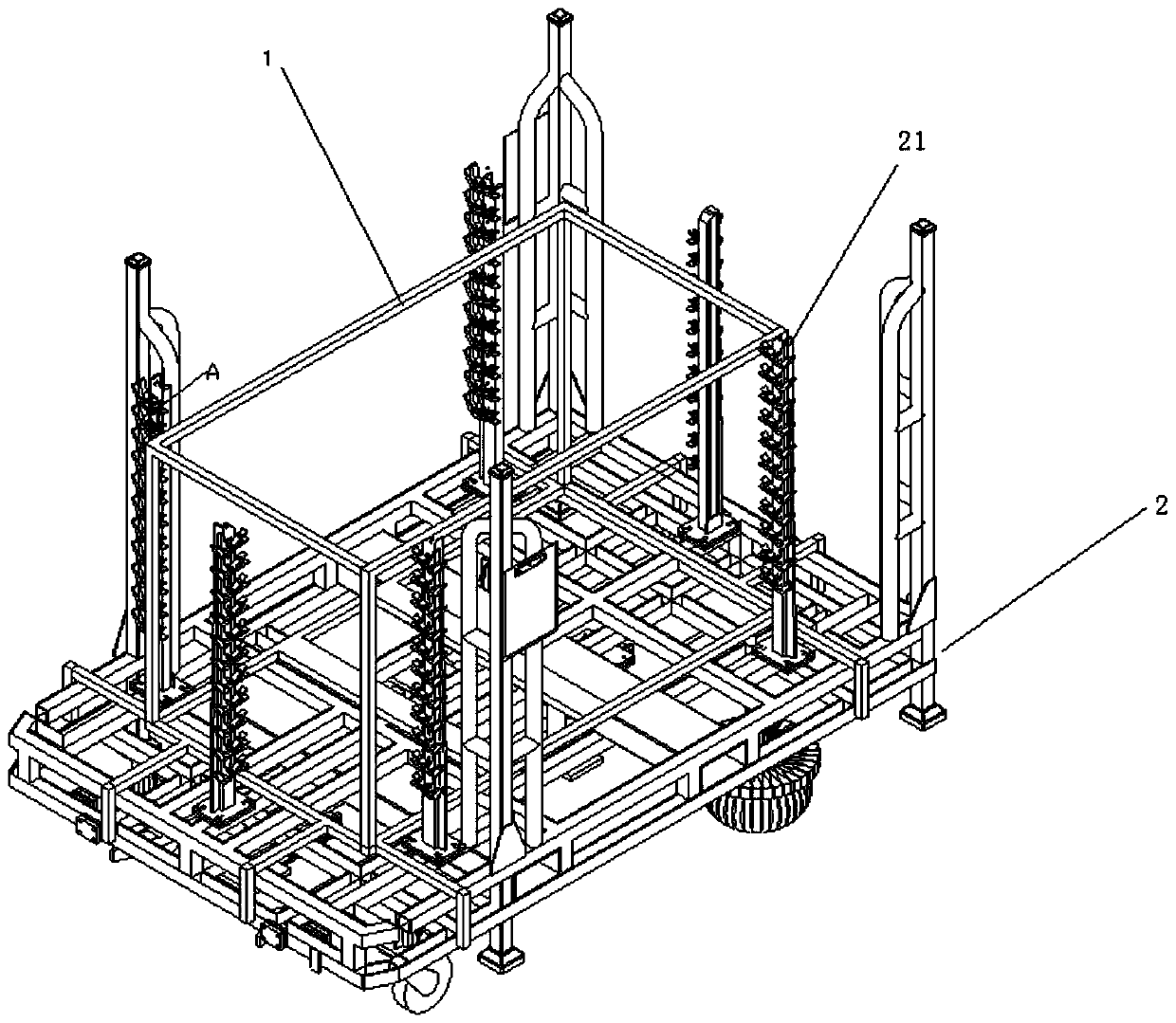

[0036] Such as figure 1 As shown, the present invention provides a kind of method for improving the precision of automatic packing system, comprises the following steps:

[0037] (1) Adjust the accuracy of the storage location: take the robot that grabs the parts through the mechanical arm as the accuracy standard, install a tooling needle on the 6# axis of the mechanical arm, the tooling needle can be purchased from the market, move the robot, and pass the tooling The needle is fixed on the four positioning pins (P1, P2, P3, P4) of the first pallet (T1), and the coordinates of the positioning pins of the first pallet are obtained. in the system;

[0038]Based on the coordinates of the positioning pins of the first pallet, repeat the first pallet in and out of each storage location (ST1, ST2, ST3, ST4, ST5, ST6, etc.) at least 3 times to verify the position of a single pallet in each storage location. Repeat positioning accuracy, if the repeat positioning accuracy error of t...

Embodiment 2

[0048] The difference from Embodiment 1 is that the specified range, precision error, horizontal distance error, numerical error, and error involved can be the same value, or can be partially the same or completely different, and can be adjusted according to the actual situation, but no matter How to set the error range, the optimization method in this embodiment is quantitative recording, and the error range of each step can be adjusted according to the final actual needs, so as to ensure that the entire cumulative error is within an acceptable range.

[0049] For example, each error range is 0.3mm or 0.6mm, etc., which are adjusted according to the actual situation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com