Manufacturing method of large-section small-radius hyperbolic box beam

A hyperbolic box type and production method technology, which is applied in the field of steel structure processing, can solve the problems of cumbersome process, long production cycle, large welding volume, etc., and achieve the effects of improving processing progress, avoiding crease bulging, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

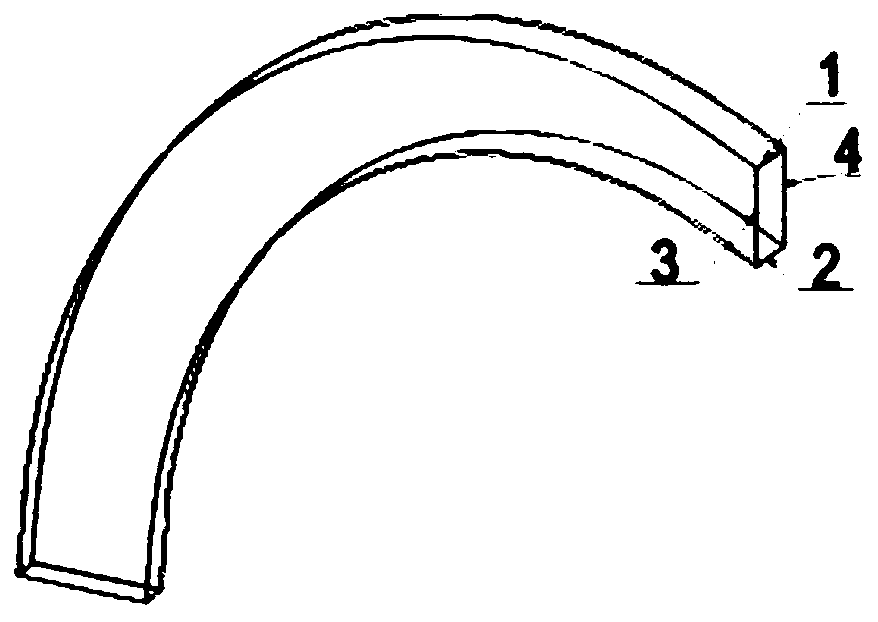

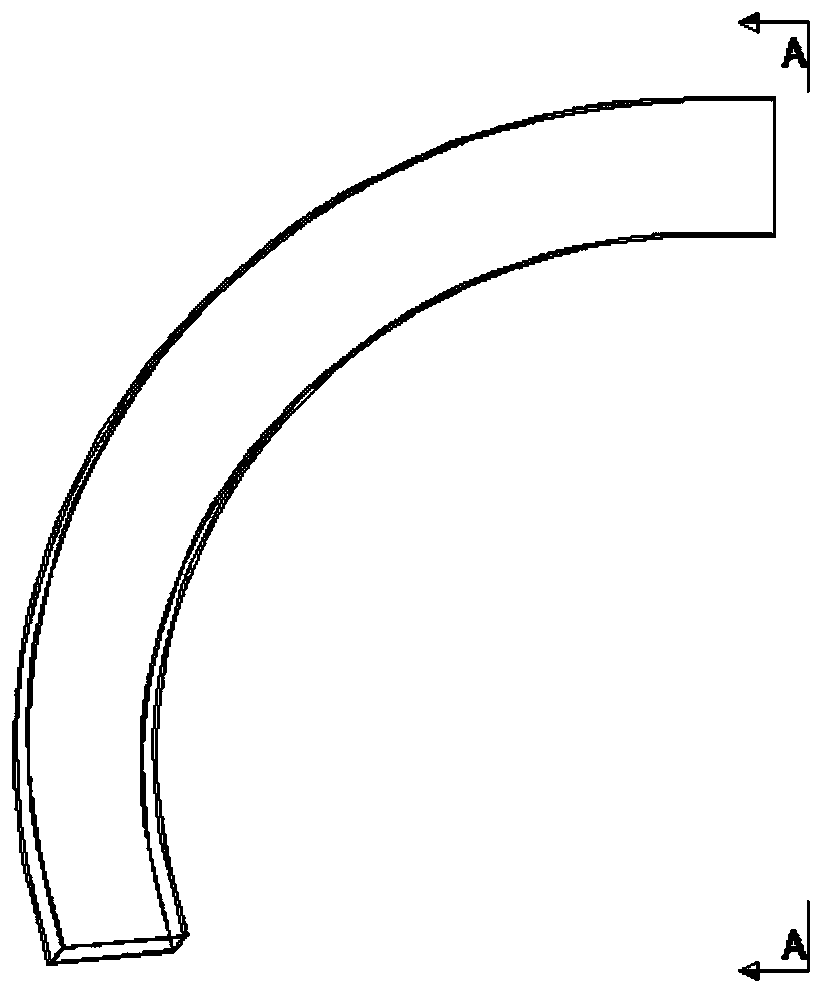

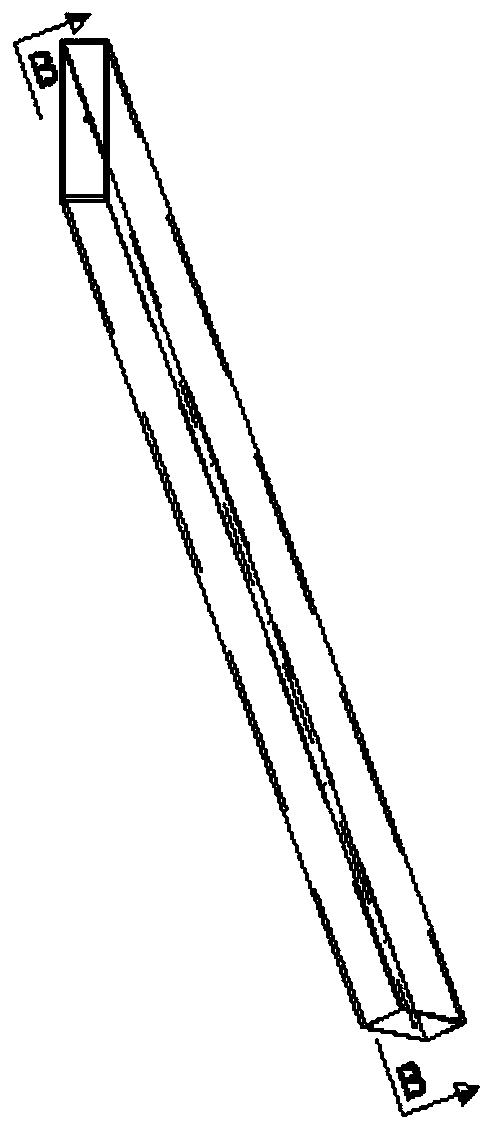

[0041] A manufacturing method of hyperbolic box girder with large cross-section and small radius

[0042] Step 1: Disassemble the drawings of the hyperbolic box girder with large cross-section and small radius to be produced. According to the theorem of three points to determine a plane, use the function of Tekla software to create a section in the drawing, in figure 2 On the basis of the front view, make a sectional view from right to left along A-A, the depth of the sectional view is until the whole part can be seen, and the sectional view is as follows image 3 shown in image 3 It can be seen that the four edges of the hyperbolic box beam with large cross-section and small radius are all straight lines; image 3 , make a section from right to left along the center line B-B of the part, the depth of the section is the entire part, and the section view is as follows Figure 4 shown; at this time in Figure 4 The arc length, straight length, angle and radius measured in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com