Ultrasonic scraping and shoveling processing device and vibration unit thereof

A technology of a processing device and a vibration unit, which is applied in the field of chipping processing devices, can solve the problems of difficult cultivation of talents, time-consuming, and bulky semi-automatic chipping machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

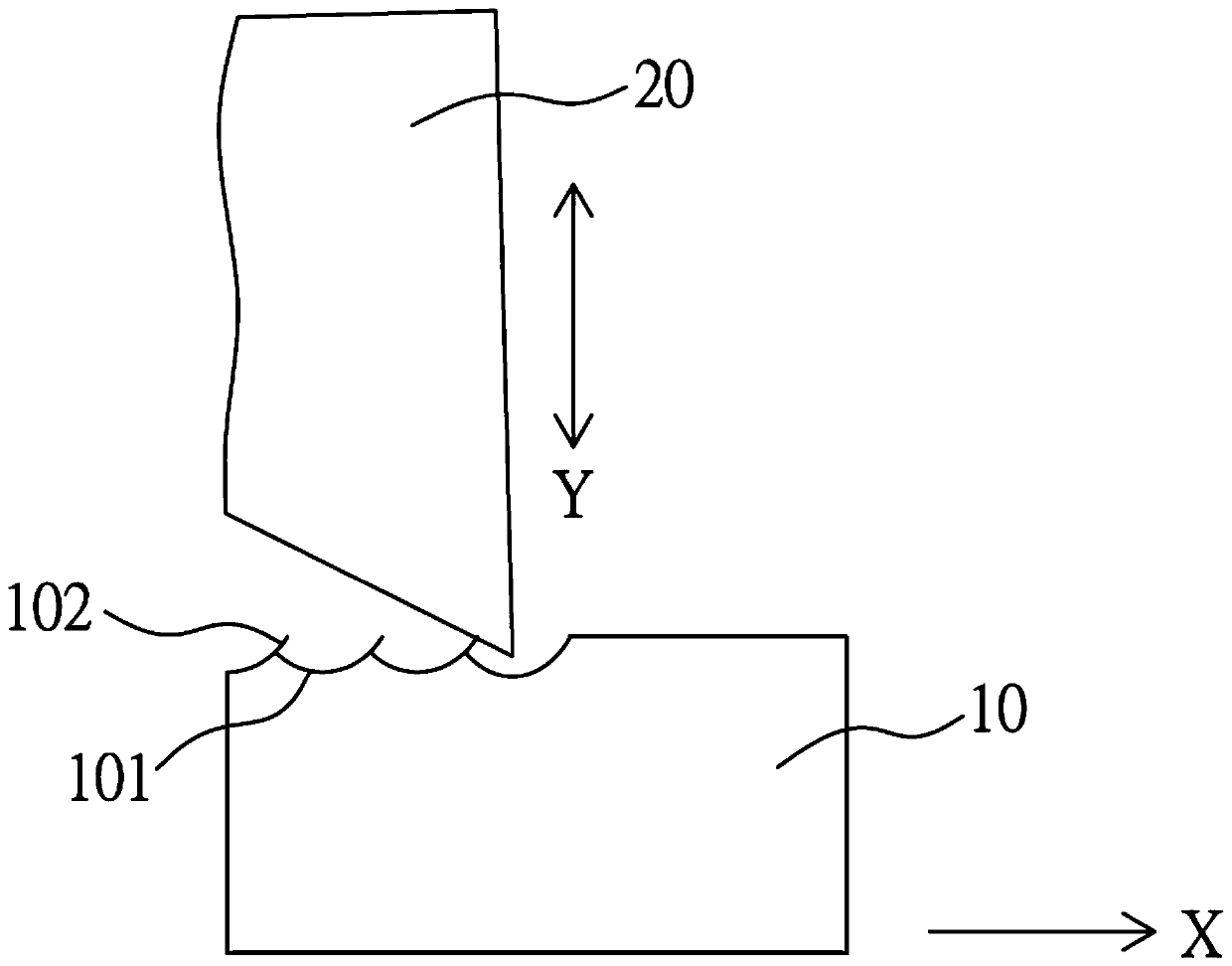

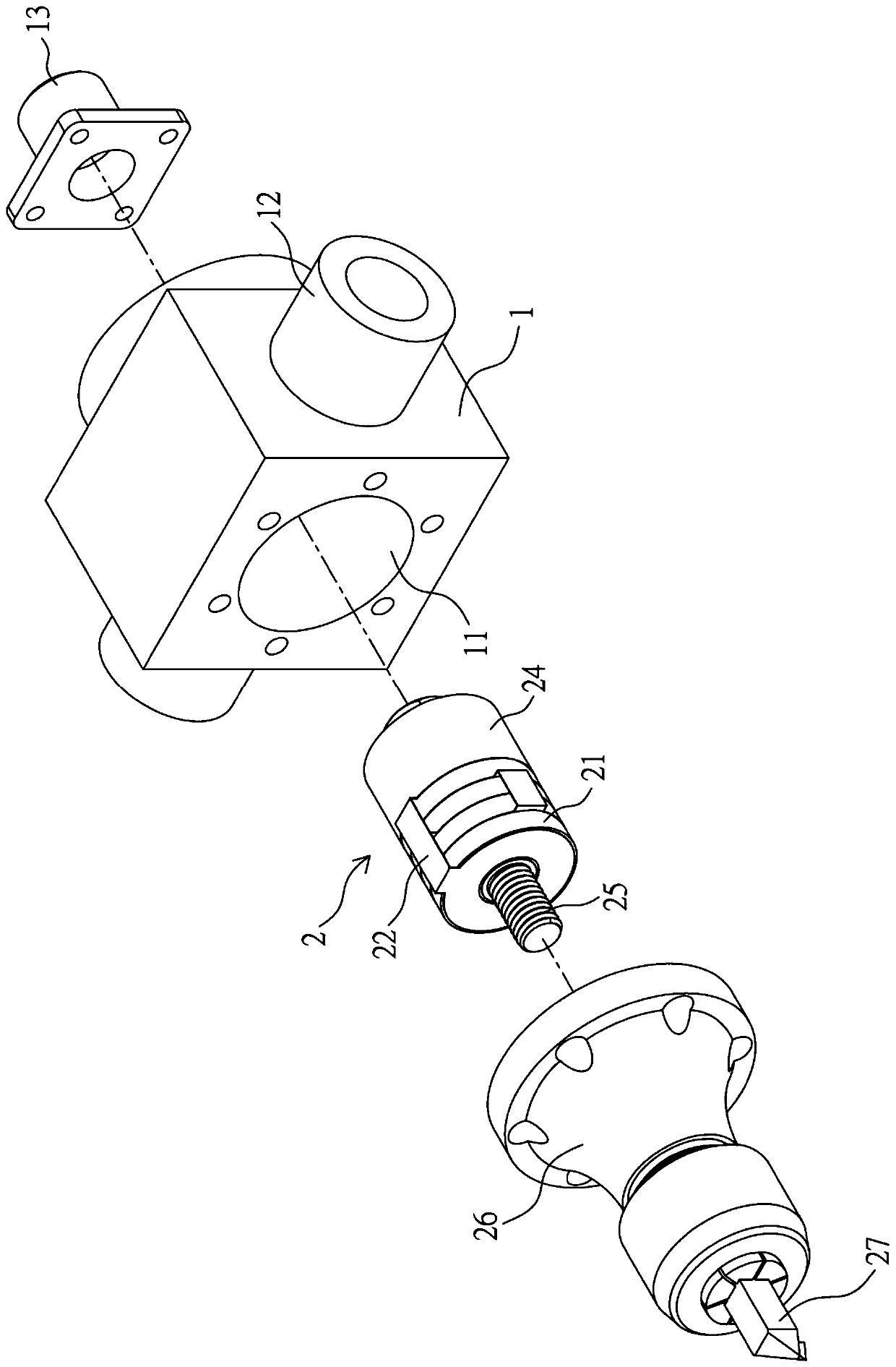

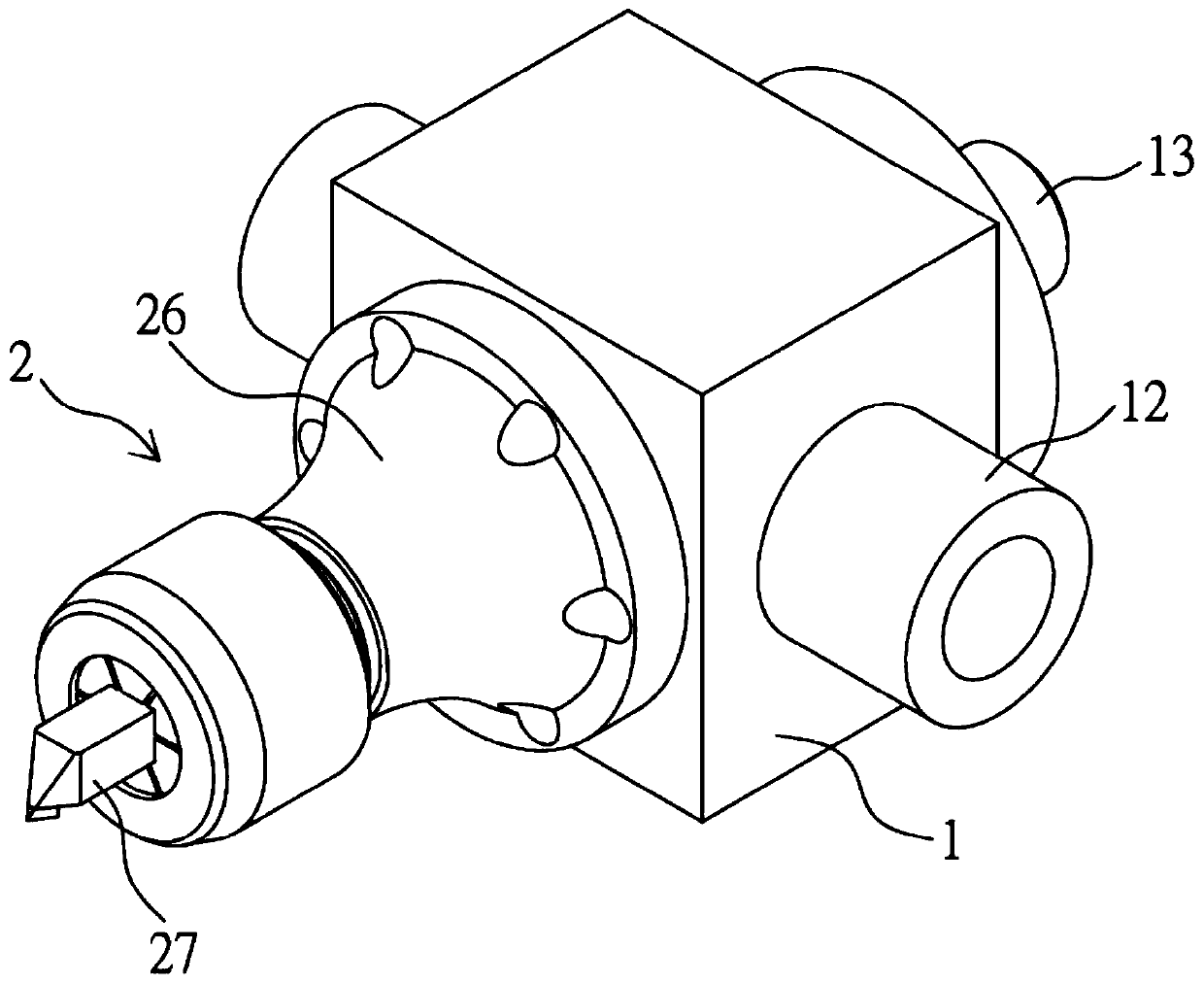

[0044] Figure 2 to Figure 4 As shown, the ultrasonic scraping processing device provided by the present invention includes a housing 1 and a vibration unit 2 .

[0045] The front of the housing 1 has an accommodating space 11 for the vibration unit 2 in the axial direction, and a connecting mechanism 12 is provided on at least one opposite side wall, such as figure 2 As shown, the connection mechanism 12 is an annular cylinder, but it is not limited thereto. In another embodiment, the pair of connection mechanisms 12 is a circular hole. Wherein the pair of connecting mechanisms 12 is provided for connecting and installing on a robot arm or a multi-axis processing machine (shown in image 3 ), so the ultrasonic scraping processing device is connected to the robot arm or the multi-axis processing machine through the connection mechanism 12, and moves with the robot arm or the multi-axis processing machine to perform scraping cutting operations.

[0046] In order to provide D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com