A kind of manufacturing method of bearing outer ring

A bearing outer ring and processing method technology, applied in the direction of manufacturing tools, metal processing equipment, and machine tools designed for grinding the rotating surface of workpieces, to achieve the effects of difficult operation, automatic processing, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

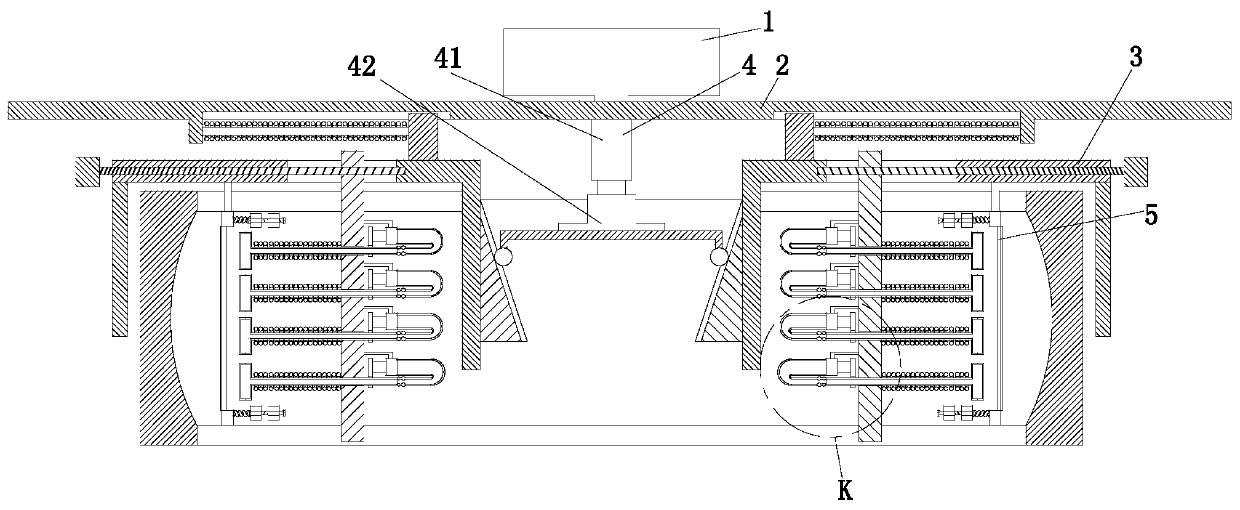

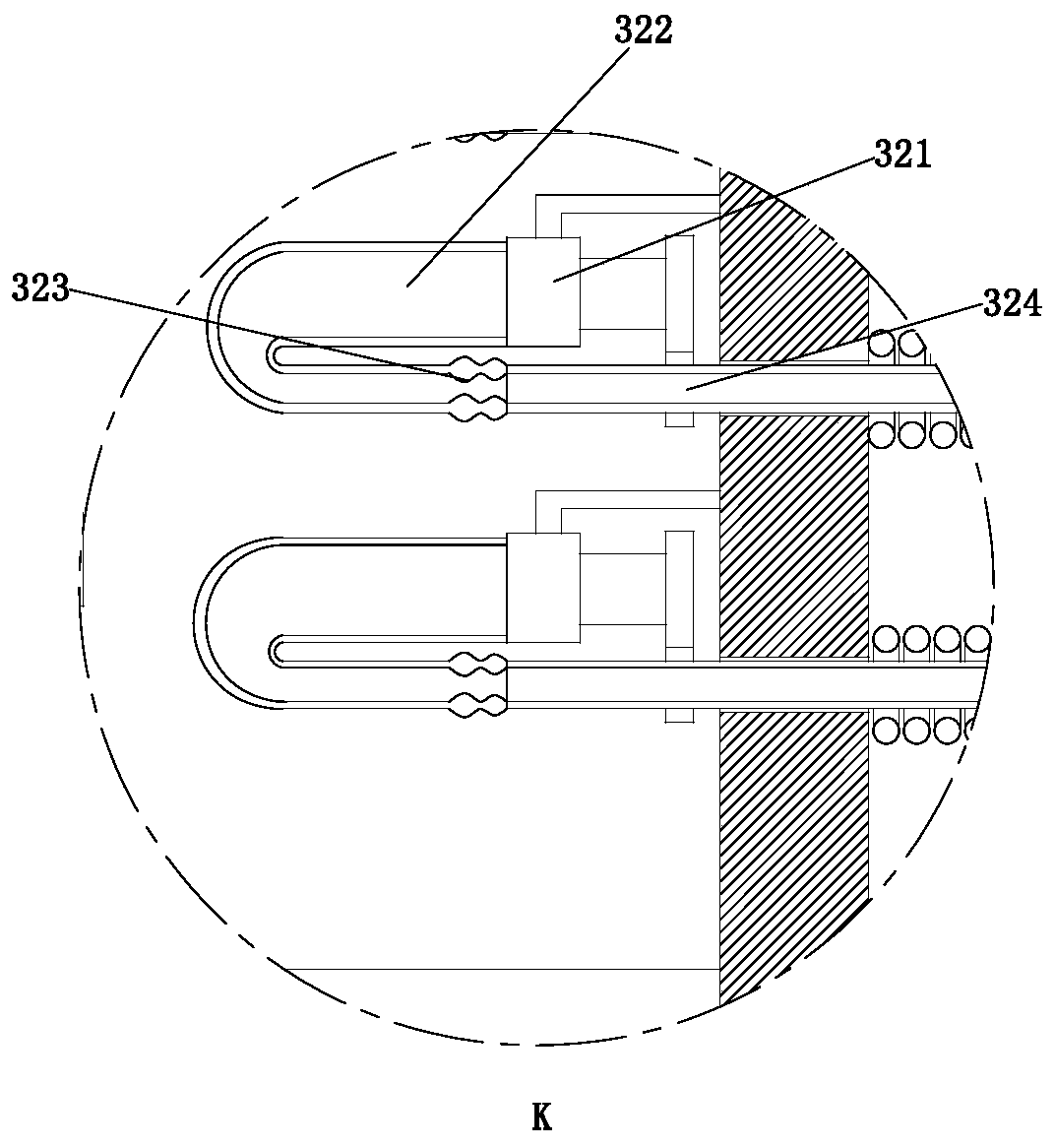

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0036] Such as Figure 1-5 As shown, a method for manufacturing and processing a bearing outer ring mainly includes the following processing steps;

[0037] Step 1. The workpiece is fixed, and the bearing outer ring to be processed is fixed by external support, and the fixed bearing outer ring is moved to the outer ring grinding equipment;

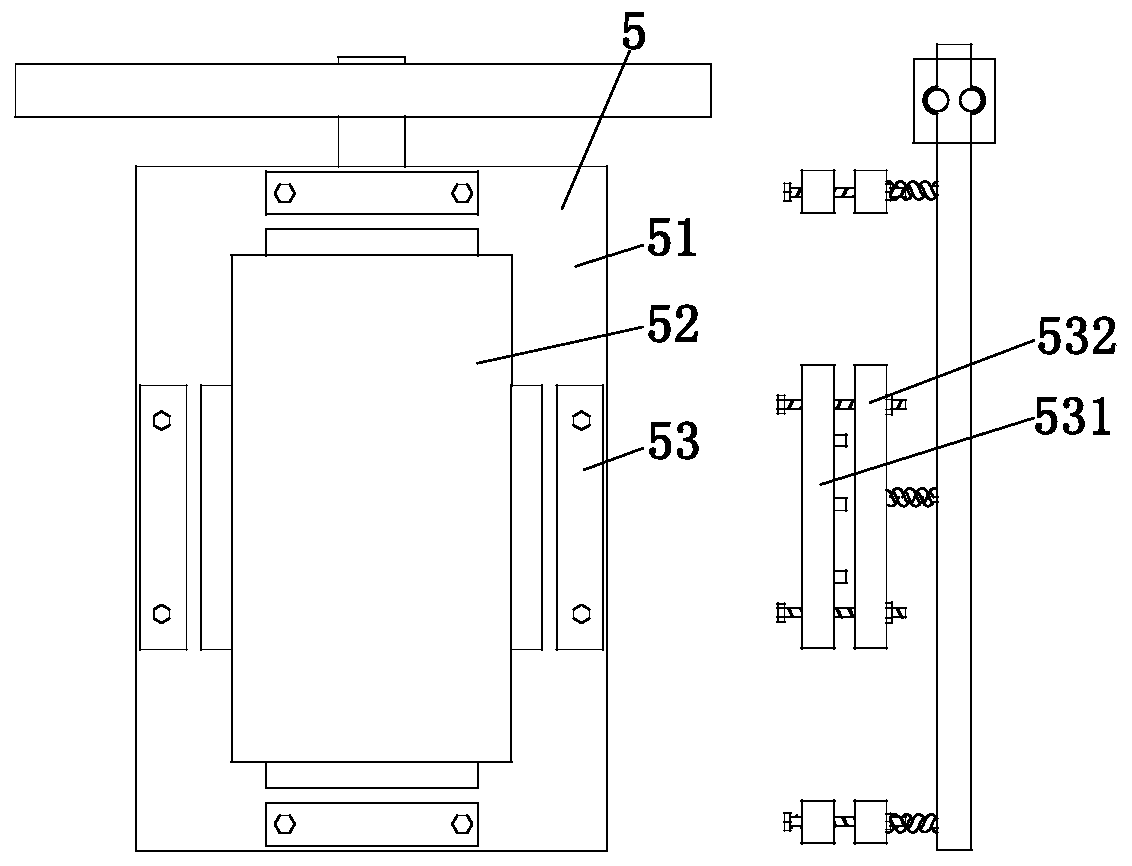

[0038] Step 2: Determine the position. The telescopic movement of the cylinder 41 drives the lower pressure bracket 42 to move up and down, and further drives the inclined fixed block 311 to expand outward or contract inward, thereby realizing the attachment of the actuator 5 to the outer rings of bearings with different diameters. combine;

[0039] Step 3: Fitting the outer ring, manually turning the lead scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com