A kind of pretreatment method of epdm colored plastic particles

A plastic granule and pretreatment technology, applied in the field of plastics, can solve the problems affecting the smoothness of adhesive laying and long storage time, and achieve the effects of reducing construction error rate, saving consumption and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The content of the present invention will be described below in conjunction with specific embodiments.

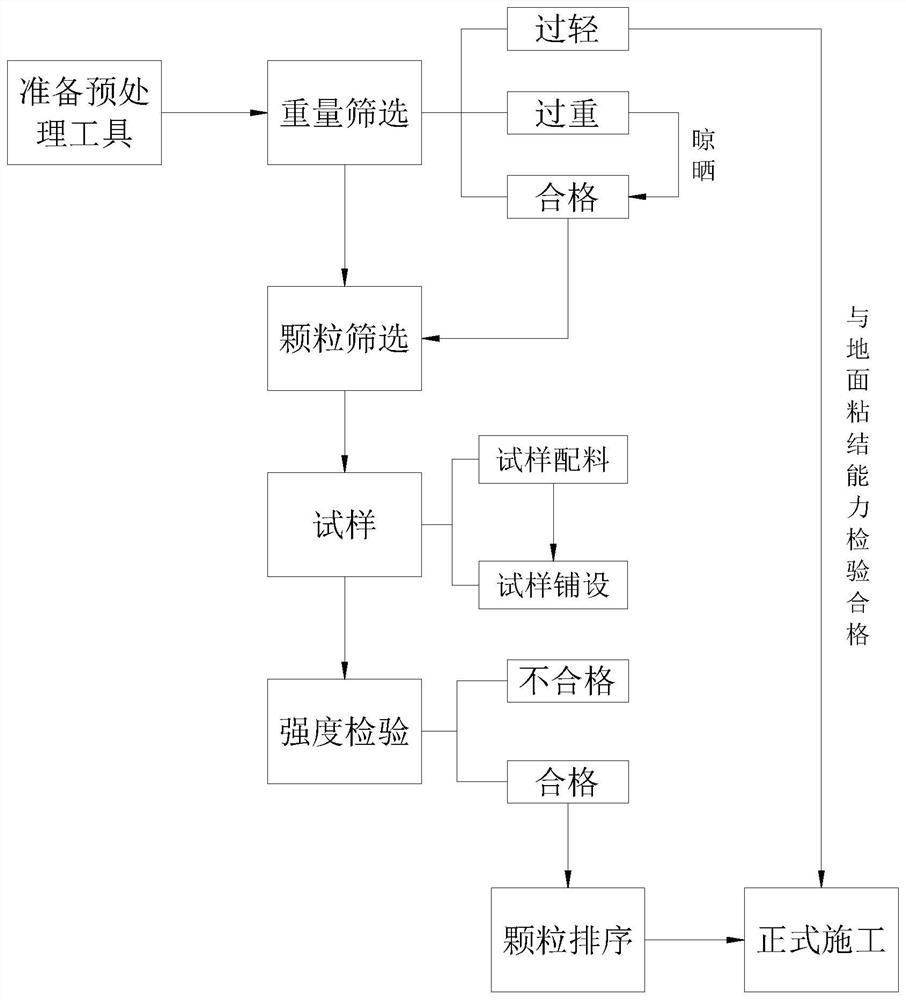

[0017] figure 1 It is the process sequence table of the pretreatment method of the present invention, such as figure 1 Shown, the pretreatment method of the present invention comprises the following steps:

[0018] Step1: Prepare pretreatment tools; the pretreatment tools include: glue, multiple sieve buckets with different sieve hole diameters, EPDM black plastic particles used as the bottom layer, EPDM colored plastic particles, and a weighing scale.

[0019] Step2: Weight screening; EPDM black plastic granules and EPDM colored plastic granules are weighed with a weighing scale in units of delivered packaging bags, and those whose weight is within the acceptable range are kept for the next step.

[0020] Step3: Particle screening. Sieve EPDM black plastic granules and EPDM colored plastic granules separately, and the sieving order is from small to large sieve ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com