Coal water slurry and preparation method thereof

A technology of coal-water slurry and pulverized coal, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of increased production cost and large fuel consumption of incinerators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

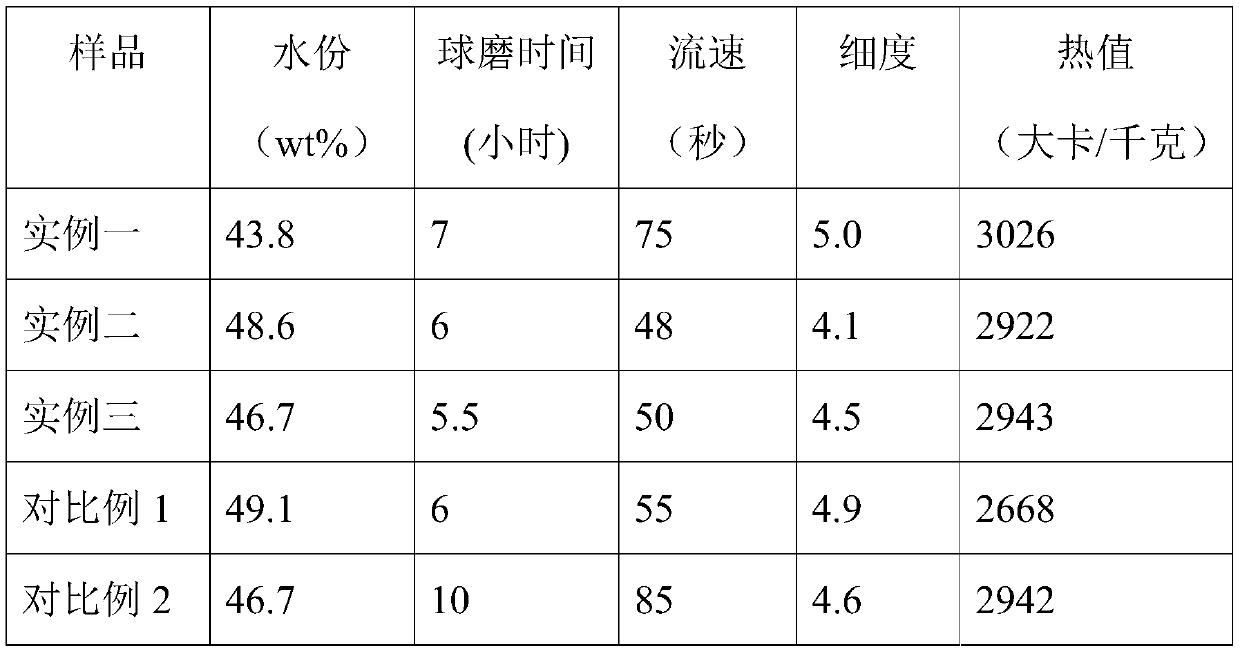

Embodiment 1

[0011] Example 1, preparing coal water slurry containing phenol water and coal tar. The raw materials for preparing the coal-water slurry include: 44% phenol water, 51.7% coal powder, 3% coal tar, 0.5% anion debonding agent A, and 0.8% composite debonding agent B. According to the ratio of raw materials, using phenolic water as the ball milling medium, anionic debonding agent A and coal powder were added to the ball mill and ground for 7 hours; then coal tar and composite debonding agent B were added to the ball mill, and then ground for 5 minutes, that is Coal water slurry with phenol water and coal tar as raw materials can be obtained. The fineness of coal water slurry is 5.0 (characterized by the proportion that cannot pass through the 200 mesh screen), and the flow rate is 75s.

Embodiment 2

[0012] Example 2, preparing coal water slurry containing phenol water and coal tar. The raw materials for preparing the coal-water slurry include: 49% phenol water, 42.3% coal powder, 8% coal tar, 0.2% anionic debonding agent A, and 0.5% composite debonding agent B. According to the ratio of raw materials, using phenolic water as the ball milling medium, anionic debonding agent A and coal powder were added to the ball mill for grinding for 6 hours; then coal tar and composite debonding agent B were added to the ball mill, and then ground for 10 minutes, that is Coal water slurry with phenol water and coal tar as raw materials can be obtained. The fineness of coal water slurry is 4.1 (characterized by the ratio that cannot pass through the 200 mesh screen), and the flow rate is 48s.

Embodiment 3

[0013] Example 3, preparing coal water slurry containing phenol water and coal tar. The raw materials for preparing the coal-water slurry include: 47% phenol water, 47% coal powder, 5% coal tar, 0.5% anionic debonding agent A, and 0.5% composite debonding agent B. According to the ratio of raw materials, with phenol water as the ball milling medium, the anionic debonding agent A and coal powder were added to the ball mill and ground for 6 hours; then coal tar and composite debonding agent B were added to the ball mill, and then ground for 8 minutes, that is Coal water slurry with phenol water and coal tar as raw materials can be obtained. The fineness of coal water slurry is 4.5 (characterized by the ratio that cannot pass through the 200 mesh screen), and the flow rate is 50s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com