Slag system for electroslag remelting containing b-type 9cr heat-resistant steel, preparation method and application method

A technology for electroslag remelting and heat-resistant steel, which is applied in the field of electroslag remelting slag to achieve good slag-gold contact, reduce viscosity and surface tension, and improve resistivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The mass percentage of the chemical composition of the slag system for the electroslag remelting containing B-type 9Cr heat-resistant alloy of the present embodiment is: CaF 2 : 54.2%, Al 2 o 3 : 22%, CaO: 19%, MgO: 3%, B 2 o 3 : 1%, impurity 0.8%; impurity in the unstable oxide SiO 2 The content accounts for 0.6% of the slag system.

[0051] The melting temperature of the slag system is 1338°C, and the viscosity of the slag system is 0.004Pa.s at a temperature of 1600°C.

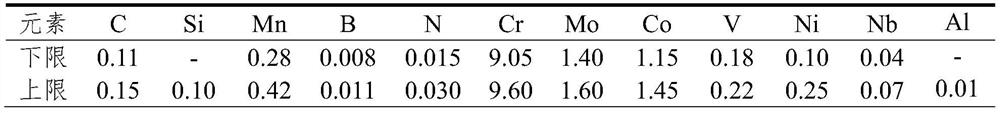

[0052] The above slag system was used for electroslag remelting, and the type of remelting alloy was COST-FB2 steel, whose composition is shown in Table 1. The alloy has a melting point of 1498°C.

[0053] Table 1 Composition requirements of FB2 steel (mass fraction / %)

[0054]

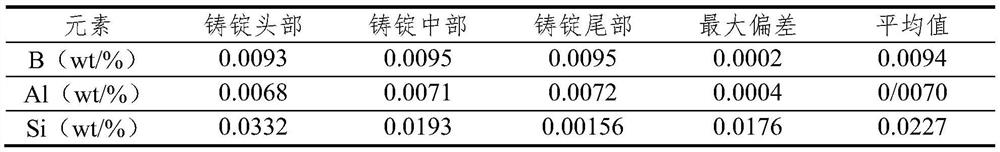

[0055] The content of B in the electrode used for electroslag remelting COST-FB2 steel is 0.01%, the content of Si is 0.05%, and the content of Al is 0.0035%. The diameter of the crystallizer is 350mm, and the qua...

Embodiment 2

[0068] The mass percentage of the chemical composition of the slag system for the electroslag remelting containing B-type 9Cr heat-resistant alloy of the present embodiment is: CaF 2 : 60%, Al 2 o 3 : 17%, CaO: 16.2%, MgO: 3%, B 2 o 3 : 3%, impurity 0.8%; impurity in the unstable oxide SiO 2 The content accounts for 0.7% of the slag system.

[0069] The melting temperature of this slag system is 1305°C. At a temperature of 1600°C, the viscosity of the slag system is 0.005Pa.s.

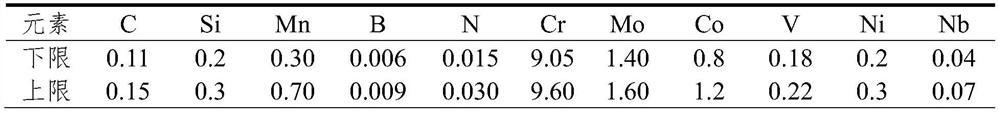

[0070] The above-mentioned slag system is used for electroslag remelting, and the type of remelting alloy is CB2 steel, and its composition is shown in Table 3. The alloy has a melting point of 1489°C.

[0071] Table 3 Composition requirements of CB2 steel (mass fraction / %)

[0072]

[0073] The content of B in the electrodes used for electroslag remelting CB2 steel is 0.009%. The diameter of the crystallizer is 280mm, and the quality of the slag is 23kg. The process of electroslag remelti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com